Light guide board and manufacturing method thereof, backlight source module as well as display device

A manufacturing method and technology of a light guide plate, applied to electric light sources, lighting devices, fixed lighting devices, etc., can solve problems such as high cost of implementation and expensive equipment for laser etching, and achieve improved design cycle, convenient manufacturing process, and improved light output. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] combine Figure 1 to Figure 4 , the manufacturing method of light guide plate of the present invention, comprises the steps:

[0038] Place nano-magnetic permeable particles on the substrate 2;

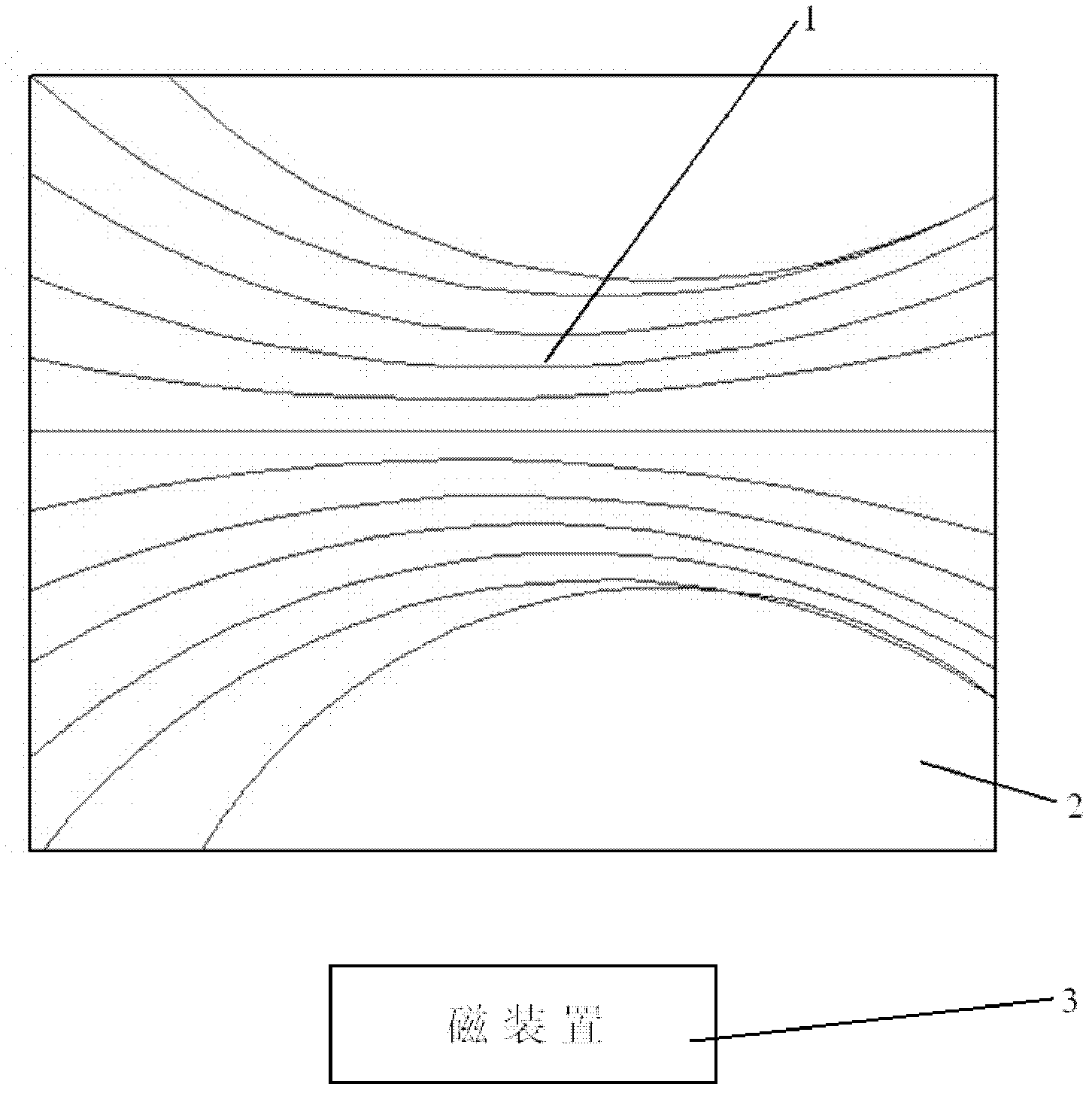

[0039] Place the substrate 2 on which the nano-magnetic permeable particles are placed in a controllable magnetic field, so that the nano-magnetic permeable particles are distributed on the substrate 2 in the form of magnetic force lines 1, such as figure 1 shown;

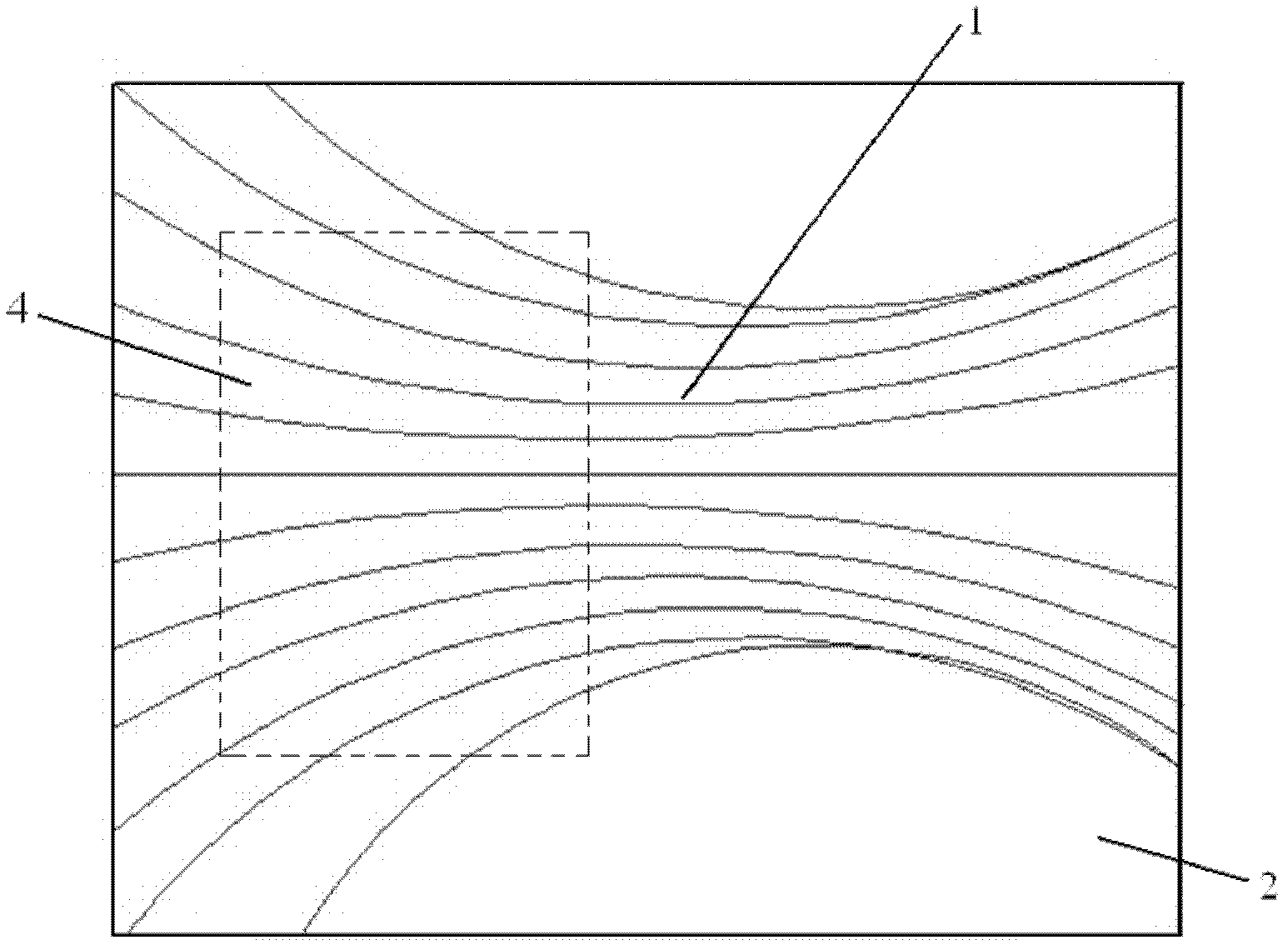

[0040] Select the setting area 4 on the substrate, such as figure 2 shown;

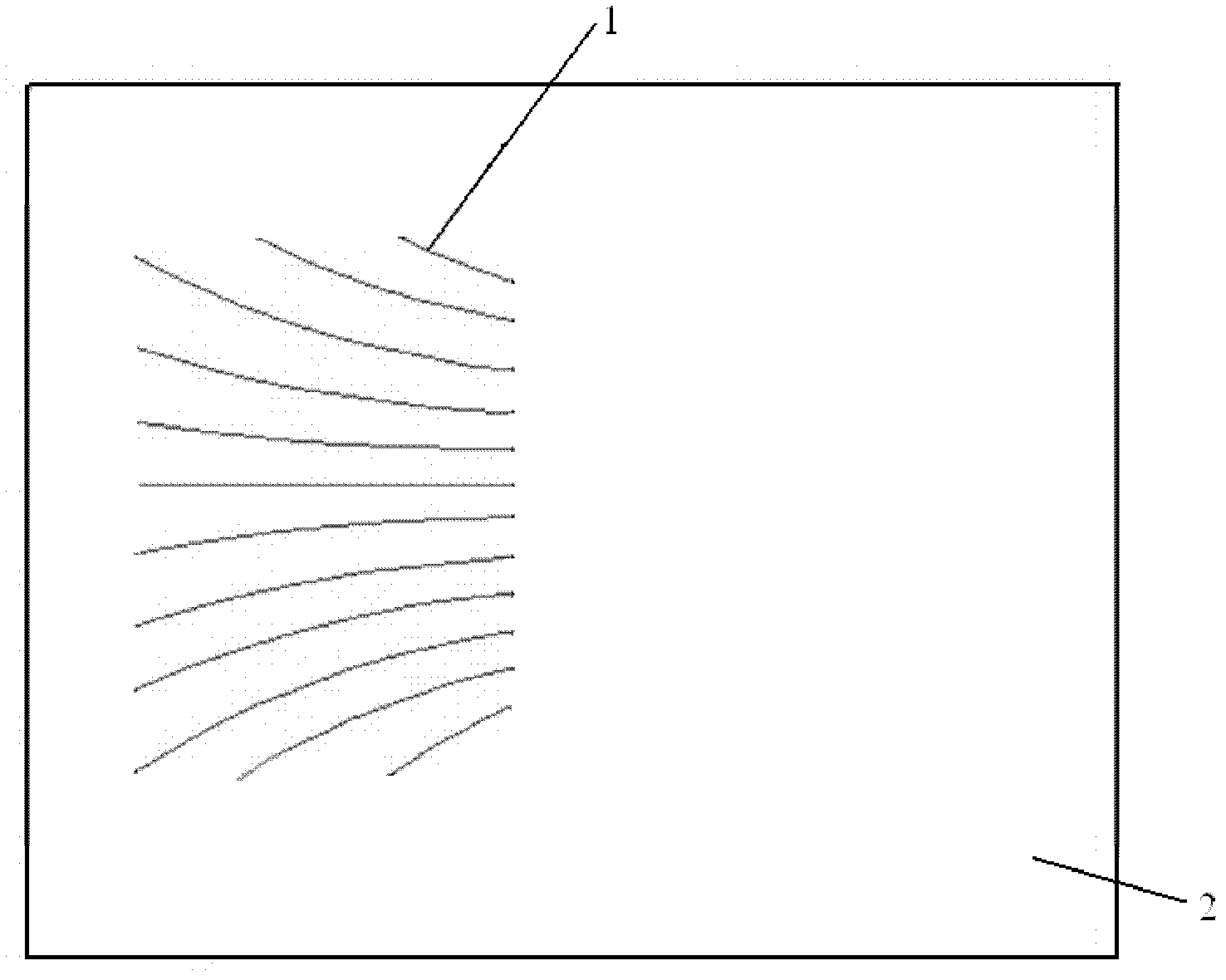

[0041] Place a light-transmitting plate above the selected area 4, and fix the distribution pattern of the magnetic field lines 1 in the nano-magnetic permeable particles located in the set area 4 on the light-transmitting plate, such as Figure 4 As shown, the preparation of the light guide plate 5 is completed.

[0042] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com