A kind of milling and grinding zirconia ceramics and its preparation method

A zirconia ceramic, milling technology, applied in the field of dental material production, to achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

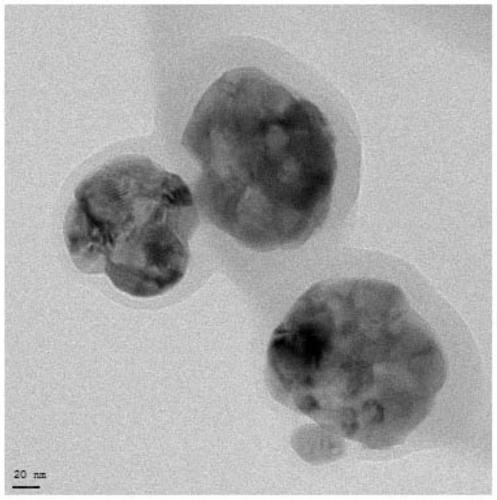

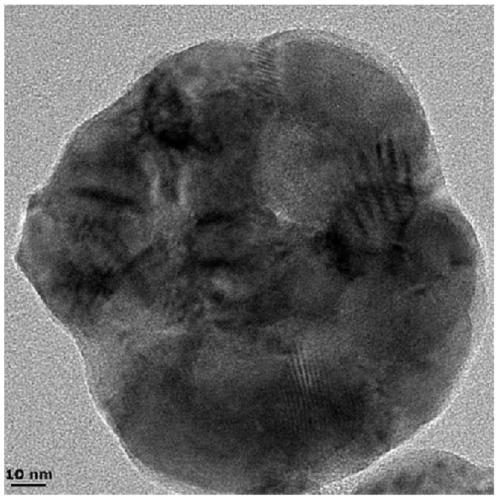

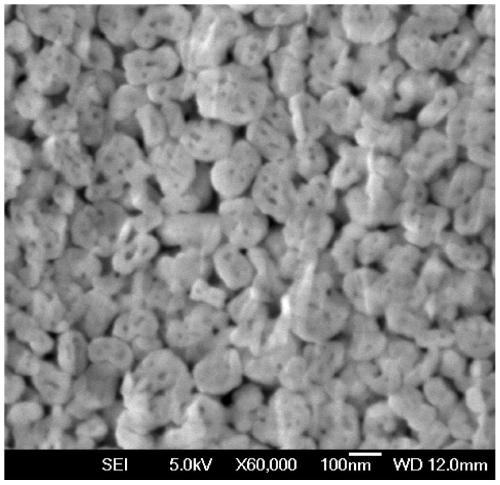

[0049] 1. Orderly merger of nanocrystals to form grains with mesoscopic crystal structure (that is, preparation of nano primary particles to controlly agglomerate into nano secondary particles)

[0050] 1.1 Controllable agglomeration of nano primary particles into nano secondary particles (grains with mesoscopic crystal structure) white powder preparation

[0051] Co-precipitation method: using zirconium and yttrium water-soluble compounds as precursors, through external heating and precise control of liquid-phase co-precipitation reactions, calcination processes and additives to produce controllable agglomeration of primary nanoparticles with different grain sizes Nano secondary particles. The precipitant is NH 4 HCO 3 and NH 3 ·H 2 O mixed solution, where NH 4 HCO 3 The volume fraction of ≤50%. The precursor solution includes a zirconium water-soluble compound: zirconium hydroxide (ZrO(OH) 2 ·nH 2 O≥99%), zirconium oxychloride (ZrOCl 2 ·8H 2 O≥99%), zirconium nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com