A two-component emulsion type polyacrylate pressure-sensitive adhesive and its preparation method and application

A polyacrylate and emulsion type technology, which is applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of low comprehensive performance of pressure-sensitive adhesives, decline, and large particle size of emulsions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

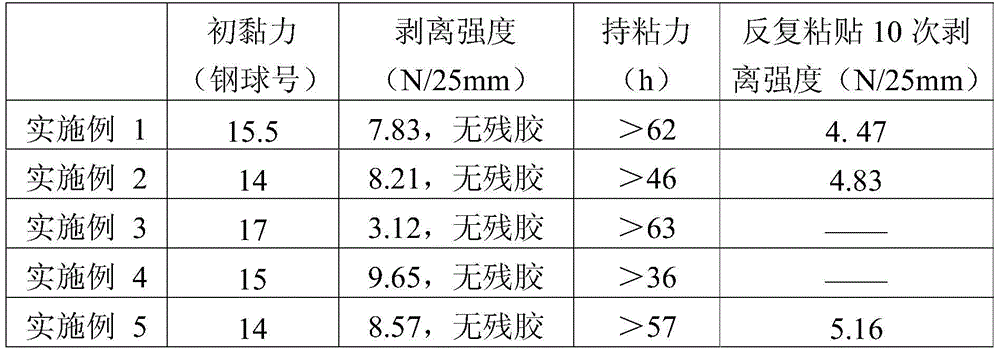

Examples

Embodiment 1

[0082] A preparation method of a two-component emulsion type polyacrylate pressure-sensitive adhesive, specifically comprising the following steps:

[0083] (1) Under the condition that the rotating speed is 400r / min stirring, put 25g deionized water, 0.4g 3-allyloxy-2-hydroxy-1-propanesulfonic acid sodium salt, 0.3g ammonium persulfate into the beaker , stir for 10 minutes and mix well; adjust the rotation speed to 800~1000r / min, then slowly add 30g butyl acrylate, 1.5g hydroxyethyl acrylate, 6g methyl acrylate, 20g isooctyl acrylate, 0.4g acrylic acid, 0.6g carboxyethyl acrylate base acrylate mixture, continue to stir for 10 minutes to obtain pre-emulsion I a ; Take out 2 g of pre-emulsion I a After that, add the remaining pre-emulsion I to the a Add 0.045g of chain transfer agent (dodecyl mercaptan) to the mixture, and disperse for 10 minutes under the dispersing condition of rotating speed 800~1000r / min to obtain pre-emulsion I b .

[0084] (2) add 25g deionized water,...

Embodiment 2

[0089] A preparation method of a two-component emulsion type polyacrylate pressure-sensitive adhesive, specifically comprising the following steps:

[0090] (1) Under the condition of stirring at a rotating speed of 400r / min, mix 50g of deionized water, 0.6g of 1-allyloxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether Ammonium sulfate and 0.5g of ammonium persulfate were placed in a beaker, stirred for 10 minutes and mixed evenly; the rotation speed was adjusted to 800-1000r / min, and then 30g of butyl acrylate, 2g of hydroxyethyl acrylate, 10g of methyl methacrylate, 15g of methyl methacrylate were slowly added. A mixture of isooctyl acrylate, 0.4 g acrylic acid, 0.8 g carboxyethyl acrylate, 0.1 g buffer (sodium carbonate), and continue stirring for 10 minutes to obtain pre-emulsion I a ; To pre-emulsion I a Add 0.08g of chain transfer agent (dodecyl mercaptan) to the mixture, and disperse for 10 minutes under the dispersing condition of rotating speed 800~1000r / min ...

Embodiment 3

[0095] A preparation method of a two-component emulsion type polyacrylate pressure-sensitive adhesive, specifically comprising the following steps:

[0096](1) Under the condition of stirring at a rotating speed of 400r / min, mix 25g of deionized water, 0.5g of 1-allyloxy-3-(4-nonylphenol)-2-propanol polyoxyethylene (10) ether Ammonium sulfate and 0.3g potassium persulfate were placed in a beaker, stirred for 10 minutes and mixed evenly; the rotational speed was adjusted to 800-1000r / min, and then 38.5g butyl acrylate, 1.4g hydroxyethyl acrylate, 8g methyl acrylate, 16.5 A mixture of g isooctyl acrylate, 0.4 g acrylic acid and 0.6 g carboxyethyl acrylate, and continue stirring for 10 minutes to obtain pre-emulsion I a ; Take out 3 g of pre-emulsion I a After that, add the remaining pre-emulsion I to the a Add 0.06g of chain transfer agent (octadecyl mercaptan) to the medium, and disperse for 10 minutes under the dispersing condition of rotating speed 800~1000r / min to obtain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com