Manufacturing method and drive unit for a drive unit for a motor vehicle servo drive

A technology of servo drive device and drive unit, which is applied in the direction of electromechanical devices, transmission parts, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

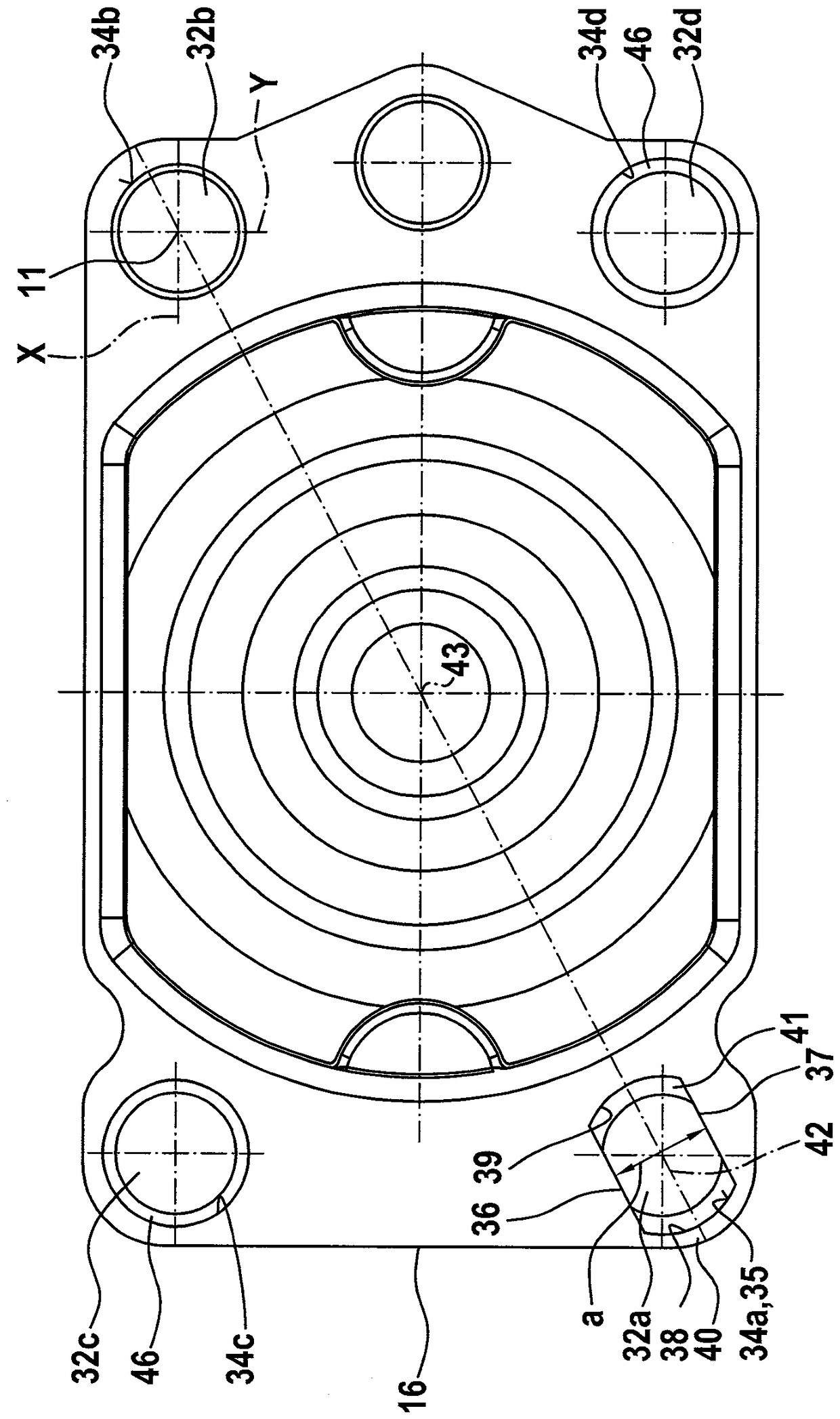

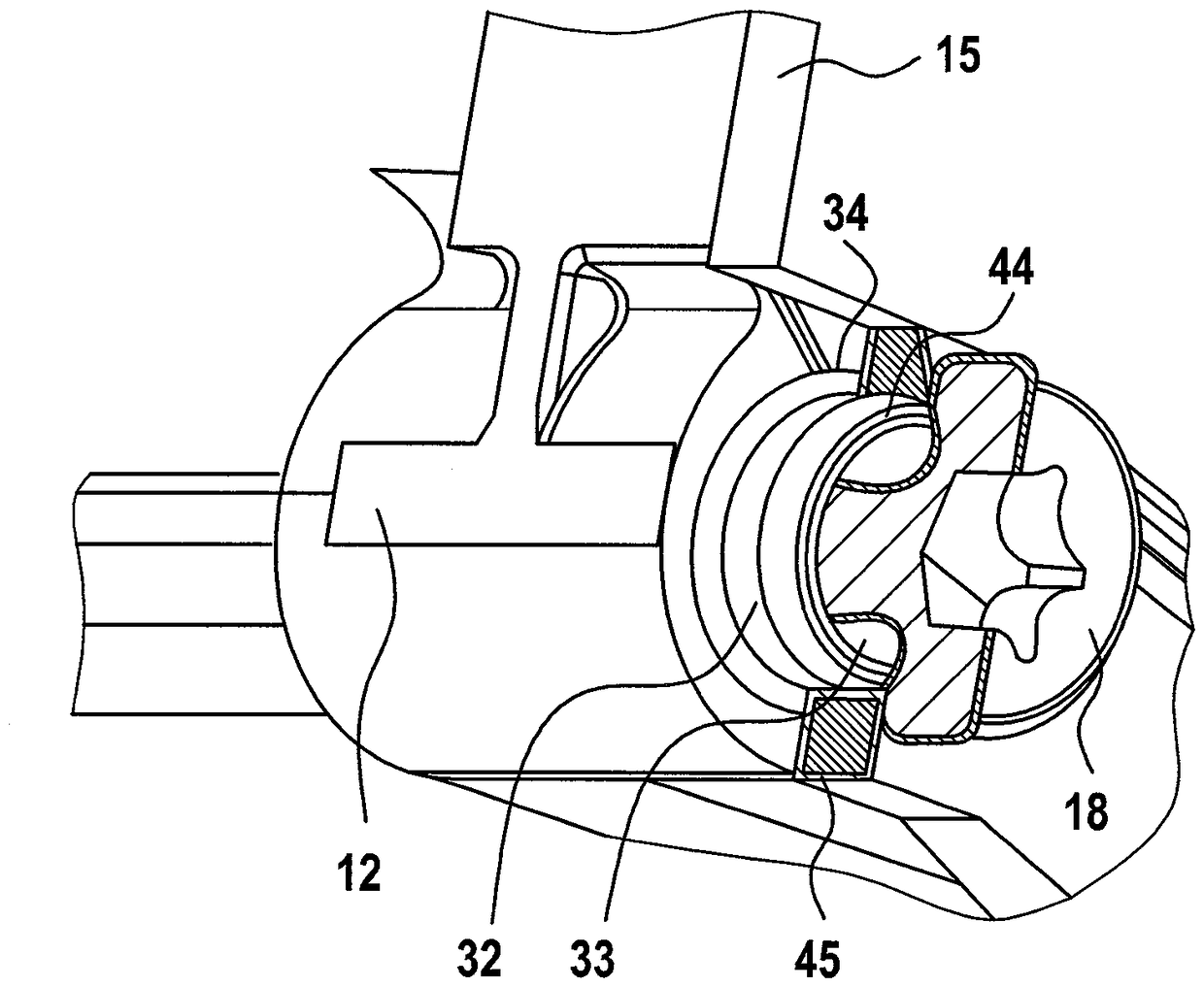

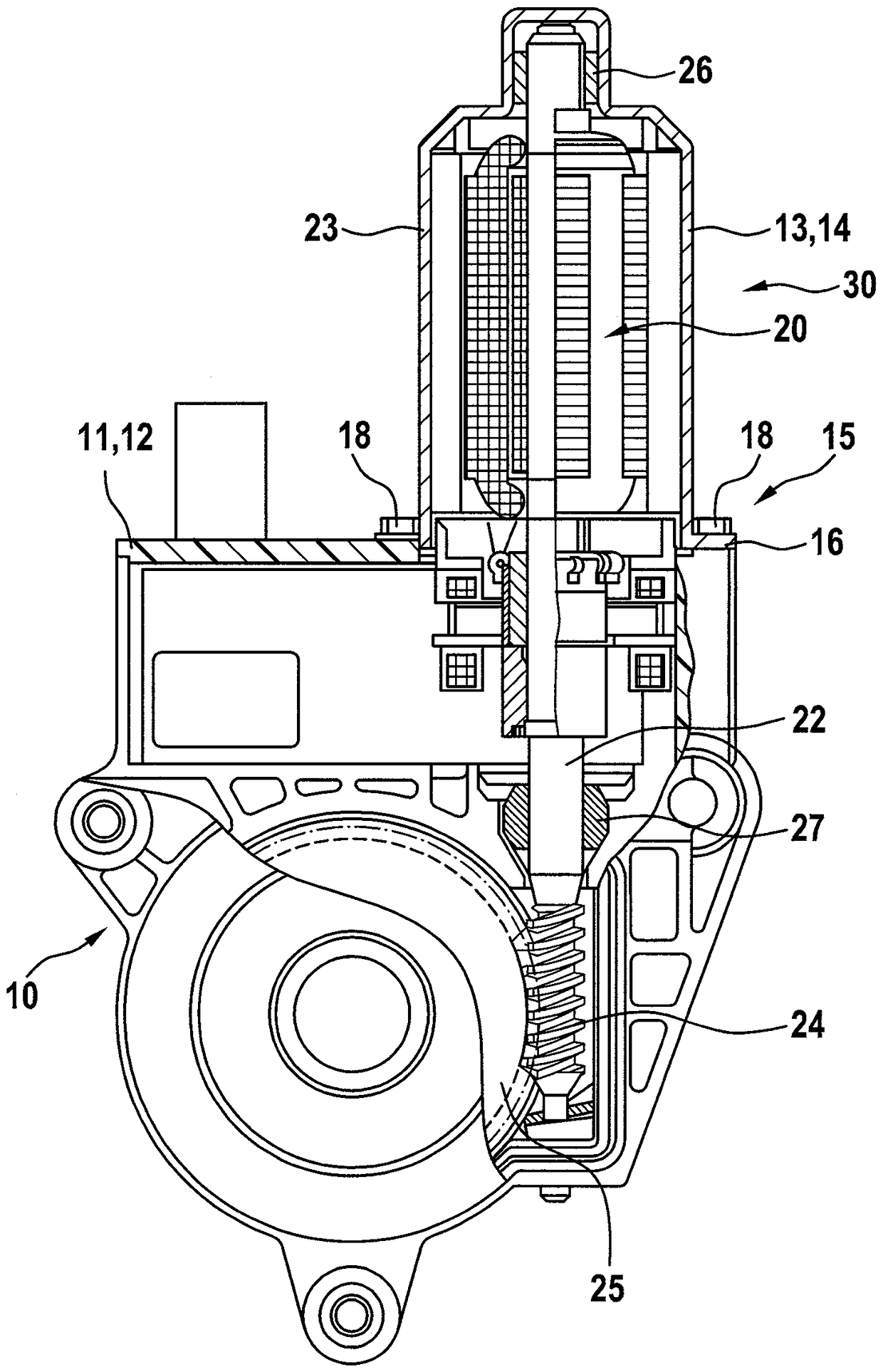

[0021] exist figure 1 The drive unit 10 shown in is provided as an actuating drive in a motor vehicle, in particular for adjusting elements not shown, such as window panes, seats, sunroof, etc. For this purpose, the drive unit 10 , which is designed as a transmission drive unit 10 , comprises a first housing part 11 , preferably made of plastic, designed as an injection molded part, which is designed in the form of a transmission housing 12 . The transmission housing 12 is connected to a second housing part 13 which serves as a motor housing and is designed in the form of a so-called pole pot 14 . The second housing part 13 is produced from sheet metal and is designed as a deep-drawn part. Fastened between the two housing parts 11 , 13 in a coupling region 15 on the end face of the transmission housing 12 via a surrounding ring formed on the second housing part 13 housing flange 16. For a releasable connection between the two housing parts 11 , 13 , a total of four fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com