Conductive anti-falling filtering bag and preparation method thereof

An anti-shedding and filter bag technology, applied in the field of filter bags, can solve the problems that the filter bag does not have the anti-static function, the static electricity of the filter bag is not eliminated in time, the fiber of the filter bag is cracked, etc. Electrostatic properties, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

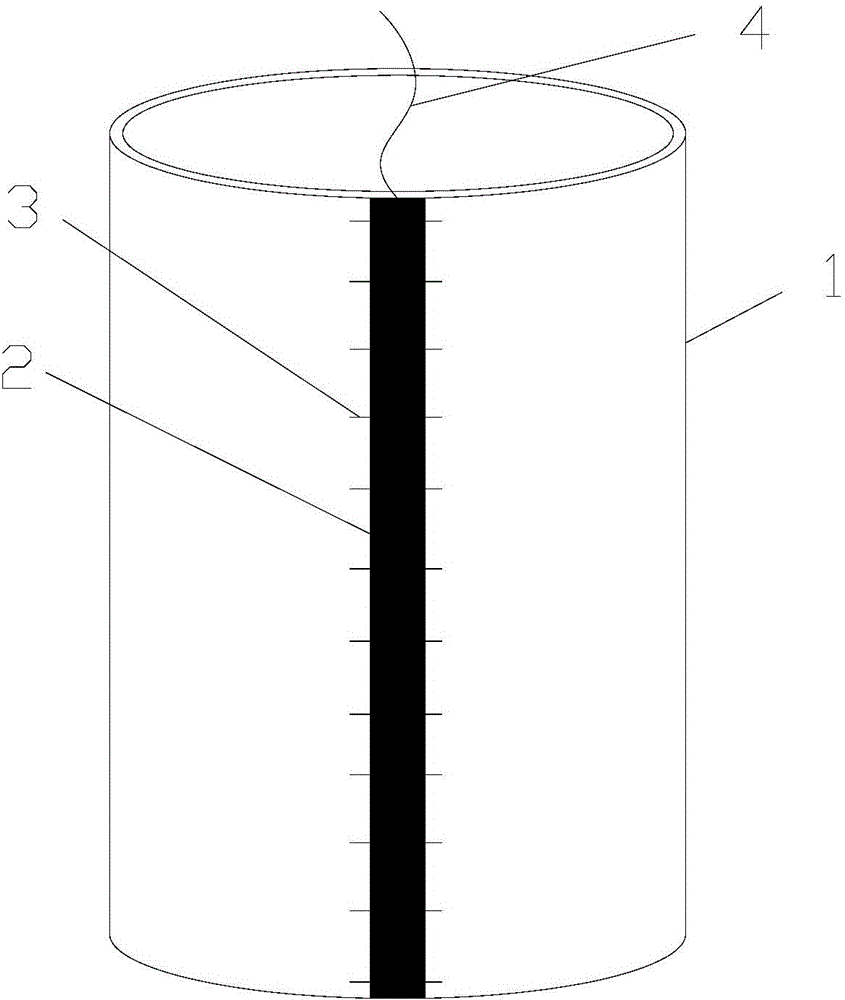

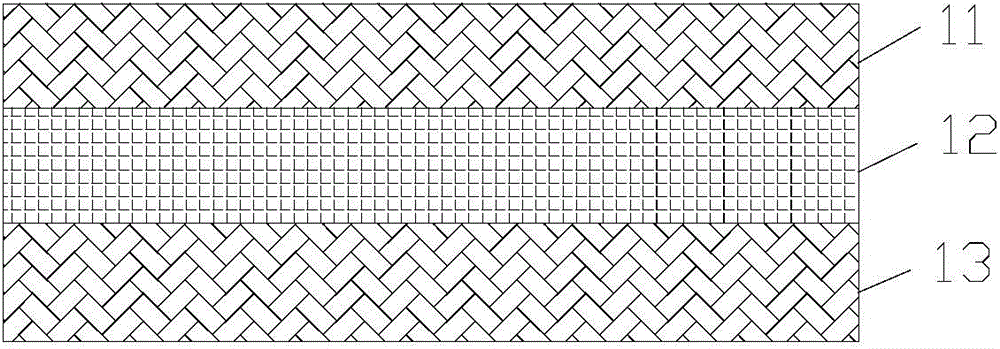

[0024] see figure 1 , figure 2 , a conductive anti-shedding filter bag provided in this embodiment, the filter bag includes a bag body 1, the bag body 1 is a three-layer composite filter material structure, and the three-layer composite filter material structure sequentially includes a dust-receiving layer 11, The base fabric layer 12 and the bottom layer 13, the dust-repellent layer 11 and the bottom layer 13 are all made of one or more fibers in polyester fibers, acrylic fibers, polyimide fibers, polyphenylene sulfide fibers, and polytetrafluoroethylene fibers. The net structure formed by disorderly entangleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com