Nitrogen desorption device

A nitrogen and desorption technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problem of activated carbon being easy to catch fire, and achieve the effect of overcoming secondary pollution of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

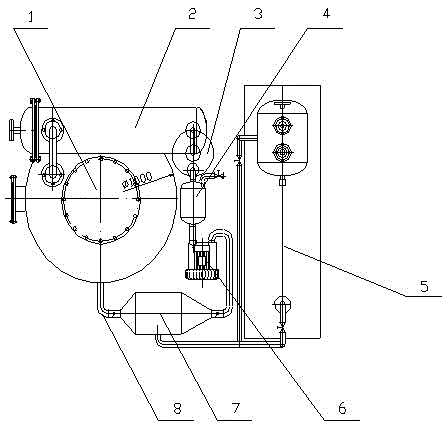

[0008] A nitrogen desorption device, the device includes an adsorber 1, a condenser 2, a solvent bucket 3, a buffer pipe 4, a heating device 5, a desorption fan 6, a nitrogen heater 7 and a nitrogen pipeline 8, and the buffer pipe 4 is provided with a nitrogen inlet, and the buffer pipe 4 is sequentially connected to the desorption blower 6, the nitrogen heater 7, the nitrogen pipeline 8 and the adsorber 1, and the nitrogen heater 7 is provided with a pipeline and connected to the heating device 5, The heating device 5 is filled with heat conduction oil, and the desorption fan 6 introduces nitrogen into the nitrogen heater 7. During the desorption process, the nitrogen is heated to 160-180°C, and the heated nitrogen is sent to the adsorber 1 through the nitrogen pipeline 8. Activated carbon is desorbed and regenerated. After desorption, the solvent is connected to the condenser 2 for condensation. After condensation, the solvent flows into the solvent barrel 3 to complete the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com