Device for drying a workpiece and method for operating such a device

A technology for drying and workpieces, which is applied in the field of drying vehicle body-device, which can solve the problems such as the deterioration of painted surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

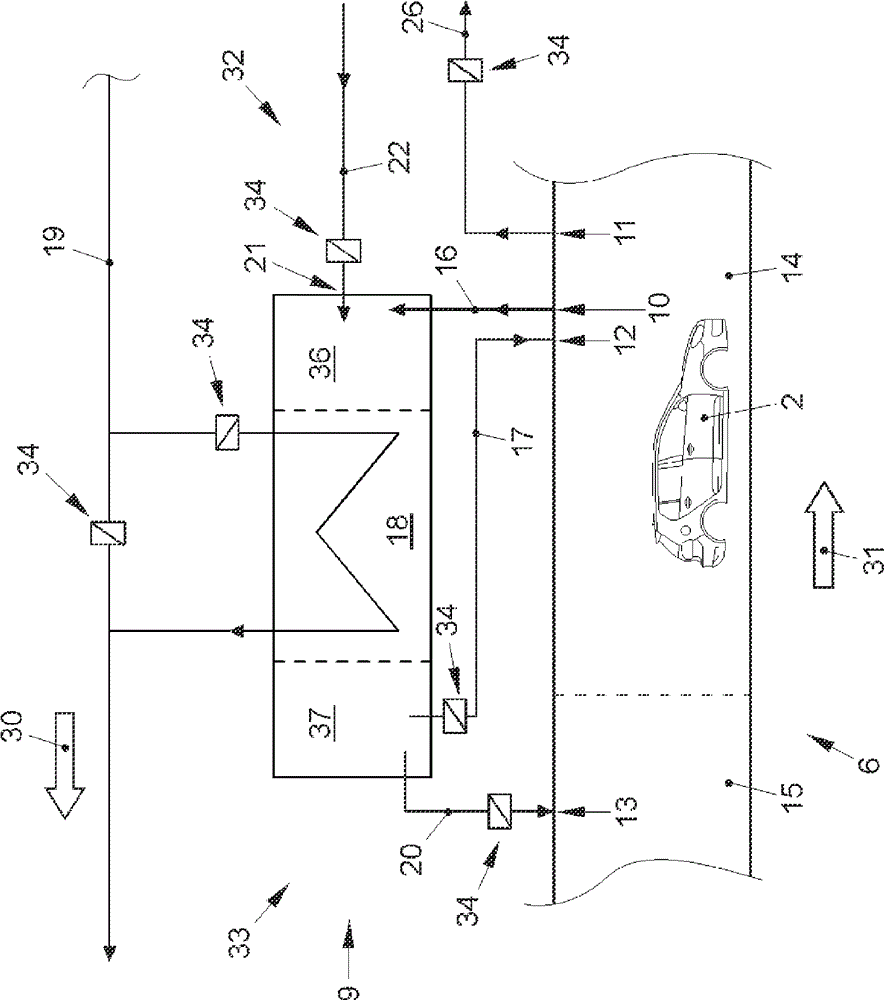

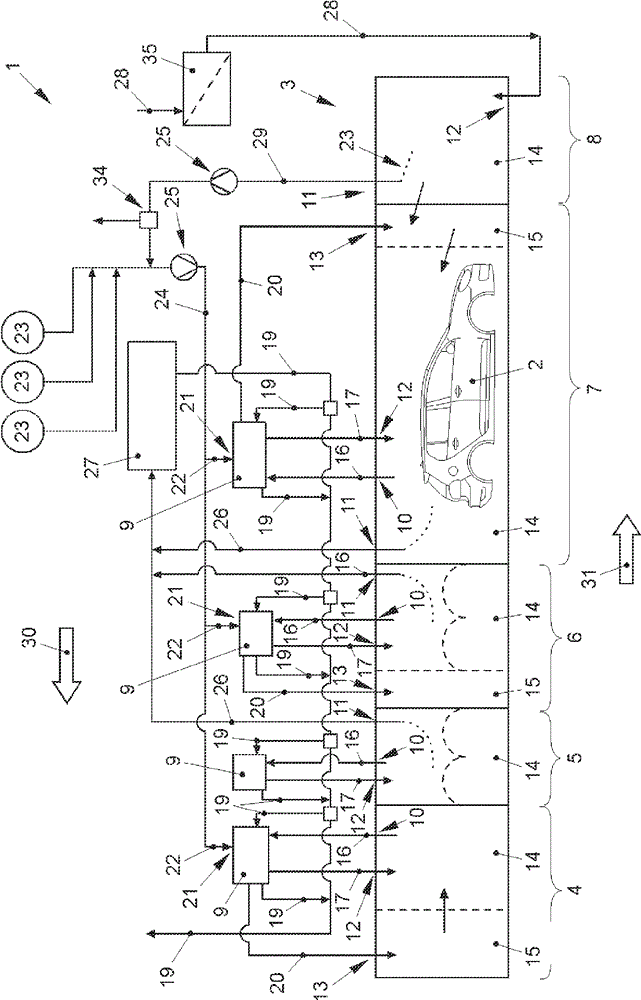

[0073] figure 1 A first embodiment of a device 1 for drying workpieces 2 is shown. The workpiece 2 is a vehicle body in the embodiment shown in the figures. The device 1 comprises a drying tunnel 3 comprising a plurality of tunnel sections 4 , 5 , 6 , 7 , 8 .

[0074] Some of the channel sections 4, 5, 6, 7 are associated with circulating air heaters 9 and each of the channel sections 4, 5, 6, 7, 8 comprises at least one air outlet 10, 11 and at least one air outlet Entrance 12,13. The air in the process chambers 14 of the channel sections 4 , 5 , 6 , 7 is circulated and heated in the circulating air heater 9 . The circulating air is fed from the air outlet 10 as chamber exhaust air 16 to the circulating air heater 9 and is then returned as chamber supply air 17 via the air inlet 12 into the process chamber 14 .

[0075] Each recirculating air heater 9 is included in the figure 2 A heat exchanger 18 is shown in , in which heat energy can be transferred from the hot prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com