Automatic-clamping and precise-positioning mechanism of pipeline in flash butt welding

An automatic clamping and flash butt welding technology, which is applied to welding equipment, tubular objects, welding equipment, etc., can solve the problems of reducing the production efficiency of pipeline flash butt welding equipment, the inability to guarantee the precise requirements of flash butt welding, and the deviation of manual installation accuracy. , to achieve the effect of simple structure, low manufacturing cost and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

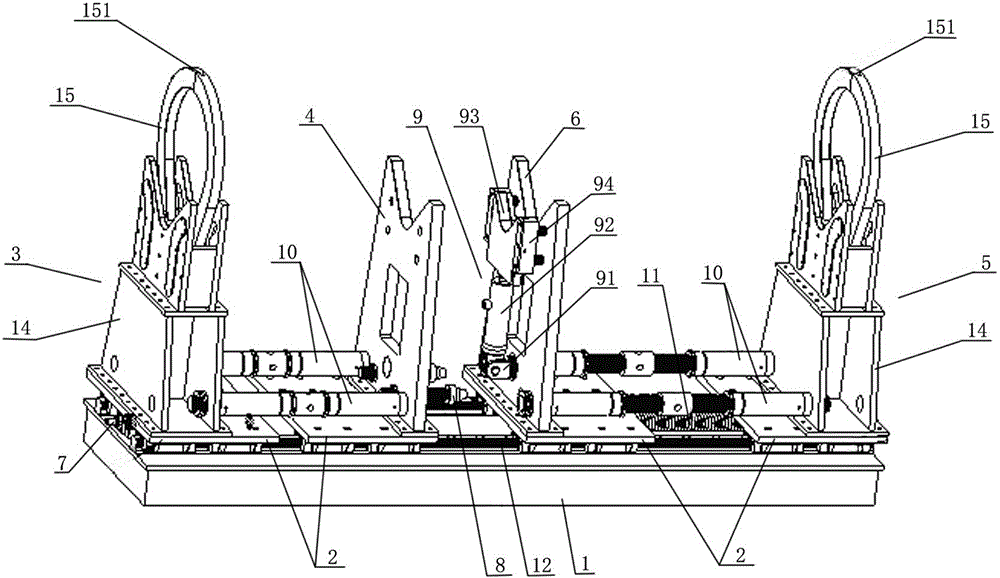

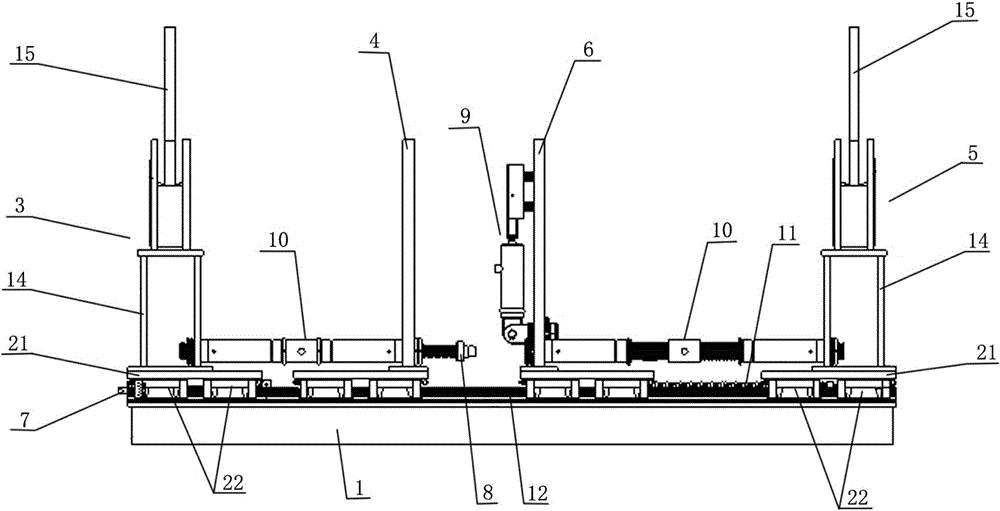

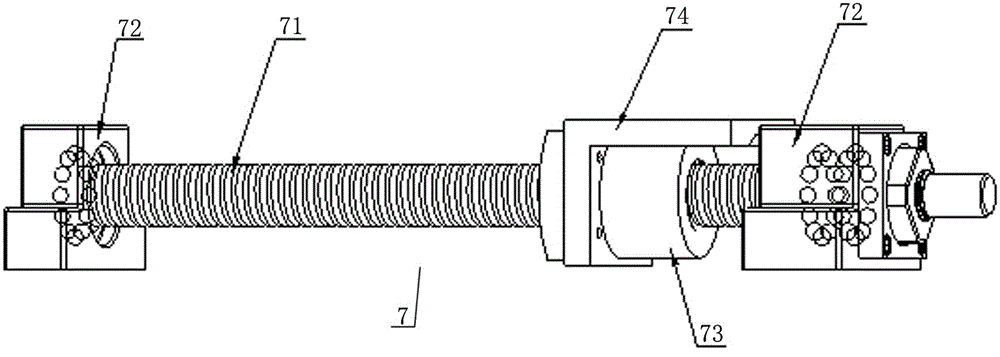

[0019] Such as Figure 1-Figure 7 As shown, the flash butt welding pipe automatic clamping precision positioning mechanism of the present invention includes a base 1, a walking mechanism A and a The traveling mechanism B, the gripping mechanism A3 arranged on one of the sliding platforms 2 of the traveling mechanism A and the support frame A4 connected with the gripping mechanism A3 on the other sliding platform 2, and one of the sliding mechanisms arranged on the traveling mechanism B The holding mechanism B5 on the platform 2 and the support frame B6 connected with the holding mechanism B5 on the other sliding platform 2 are provided with a wire for driving the walking mechanism A to walk between the walking mechanism A and the base 1. Rod drive mechanism 7, the support frame A4 is provided with a distance column 8 that can be adjusted to contact with the support frame B6 during use, and the side of the support frame B6 near the distance column 8 is provided with a longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com