Wine box facial tissue automatic positioning and forming machine as well as automatic positioning and adjusting method

A technology of automatic positioning and adjustment method, applied in paper/cardboard containers, container manufacturing machinery, decorative arts, etc., can solve the problems of low efficiency of manual positioning, achieve accurate alignment, ensure alignment accuracy, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention are described with reference to the above drawings.

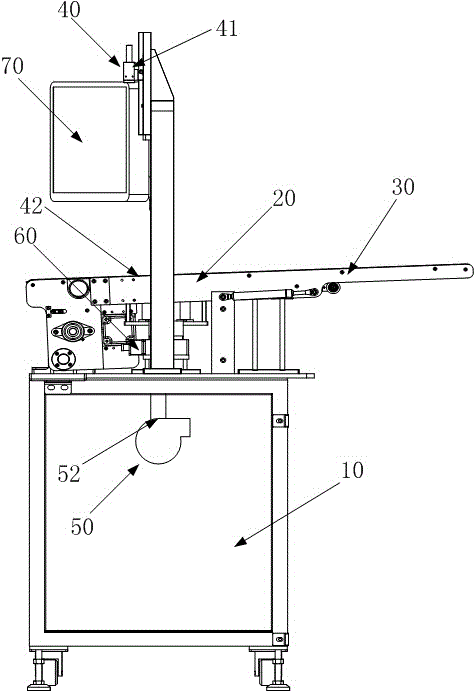

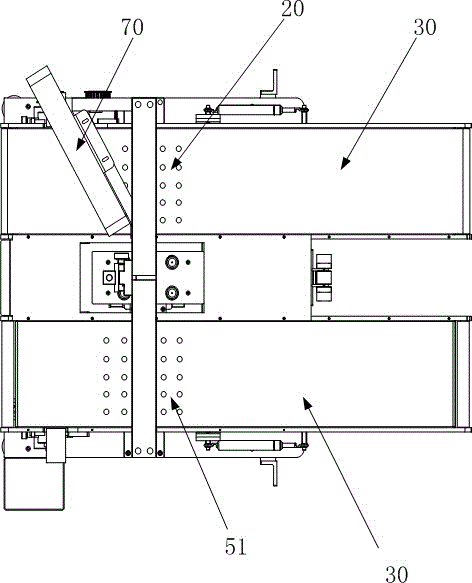

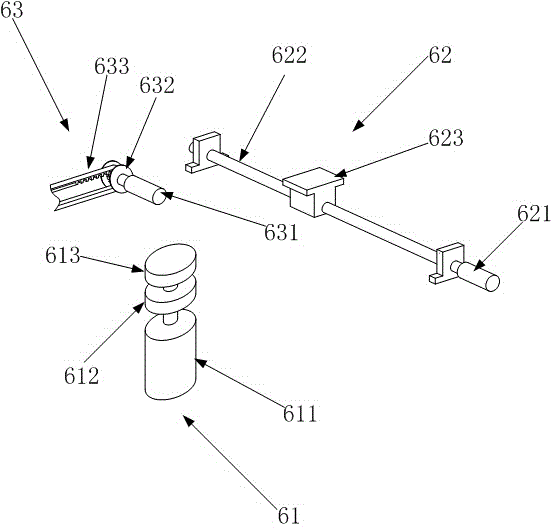

[0011] Depend on Figure 1 to Figure 3 It can be seen from the figure that the wine box face paper automatic positioning molding machine of the present invention includes a frame 10, a positioning platform 20 arranged on the frame 10, and a transmission mechanism 30 for transporting the face paper to the positioning platform 20, and also includes a frame set on the positioning platform 20. The imaging device 40 on the positioning platform 20, the positioning mechanism 50 and the adjustment mechanism 60 arranged between the frame 10 and the positioning platform 20, further include a control system 70 for controlling the positioning mechanism 50 and the adjustment mechanism 60, so The camera system 40 is electrically connected to the control system 70 . The camera device 40 includes a CCD camera 41 arranged above the positioning platform 20 , and a backlight 42 arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com