Intelligent hydraulic suspension unit and control method thereof

A hydraulic suspension, intelligent technology, applied in the direction of suspension, elastic suspension, interconnection system, etc., can solve the problem of detection of inoperable state, failure of sealing ring buffer mechanism, fatigue failure of cylinder and piston, wear failure, poor control characteristics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

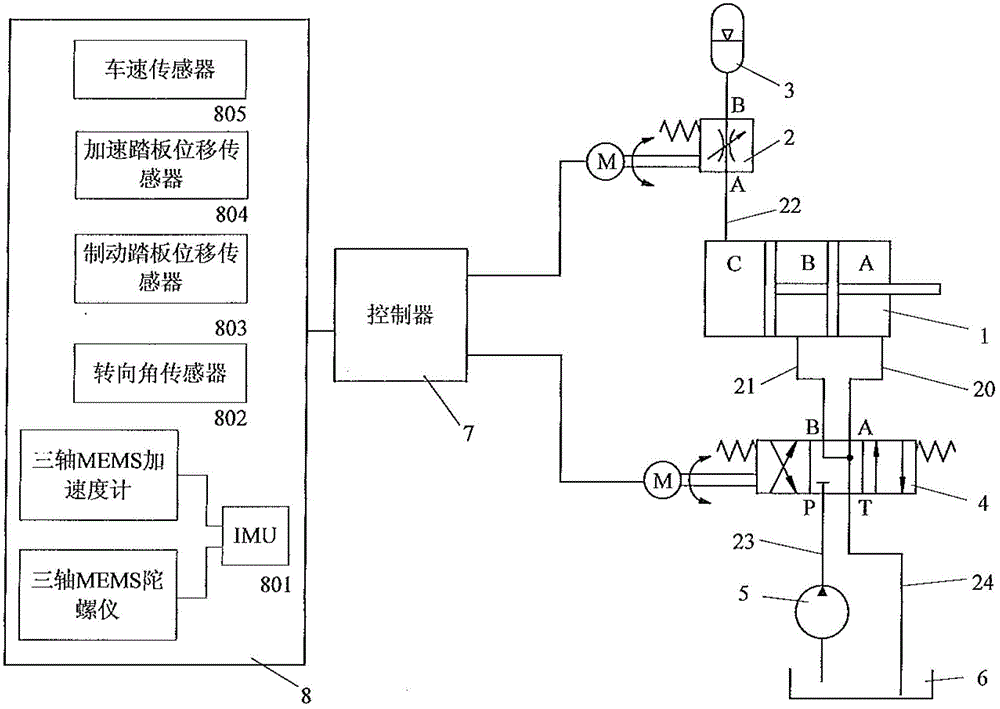

[0047] The schematic diagram of the structure of the hydraulic suspension unit of the present invention is as follows: figure 1 As shown, it consists of a hydraulic cylinder 1, a digital throttle valve 2, an accumulator 3, a digital directional valve 4, a hydraulic pump 5, an oil tank 6, a controller 7 and a motion parameter detection module 8.

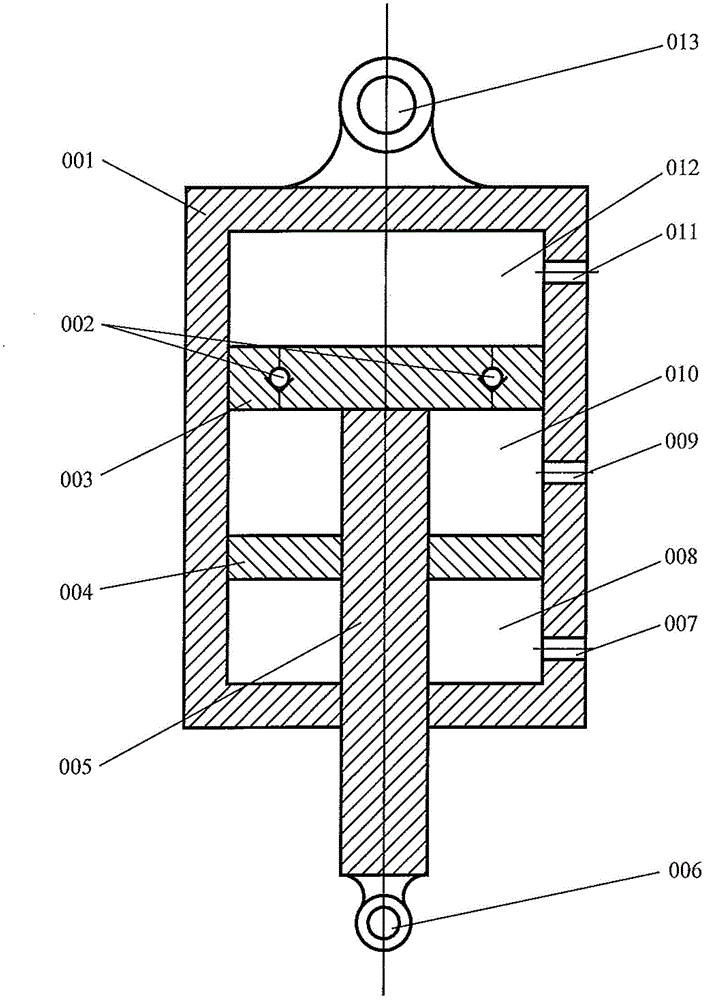

[0048] Schematic diagram of the hydraulic cylinder figure 2 As shown, cylinder 001 is cylindrical, and pistons 003 and 004 divide the cylinder into chamber A 008, chamber B 010 and chamber C 012. Each chamber communicates with the external oil circuit through port 007, port 009 and port 011 Connected, the piston rod 005 rigidly connects the two pistons, the piston 003 is equipped with check valves 002 evenly distributed along the circumferential direction, so that the oil in the B chamber 010 can enter the C chamb...

Embodiment 2

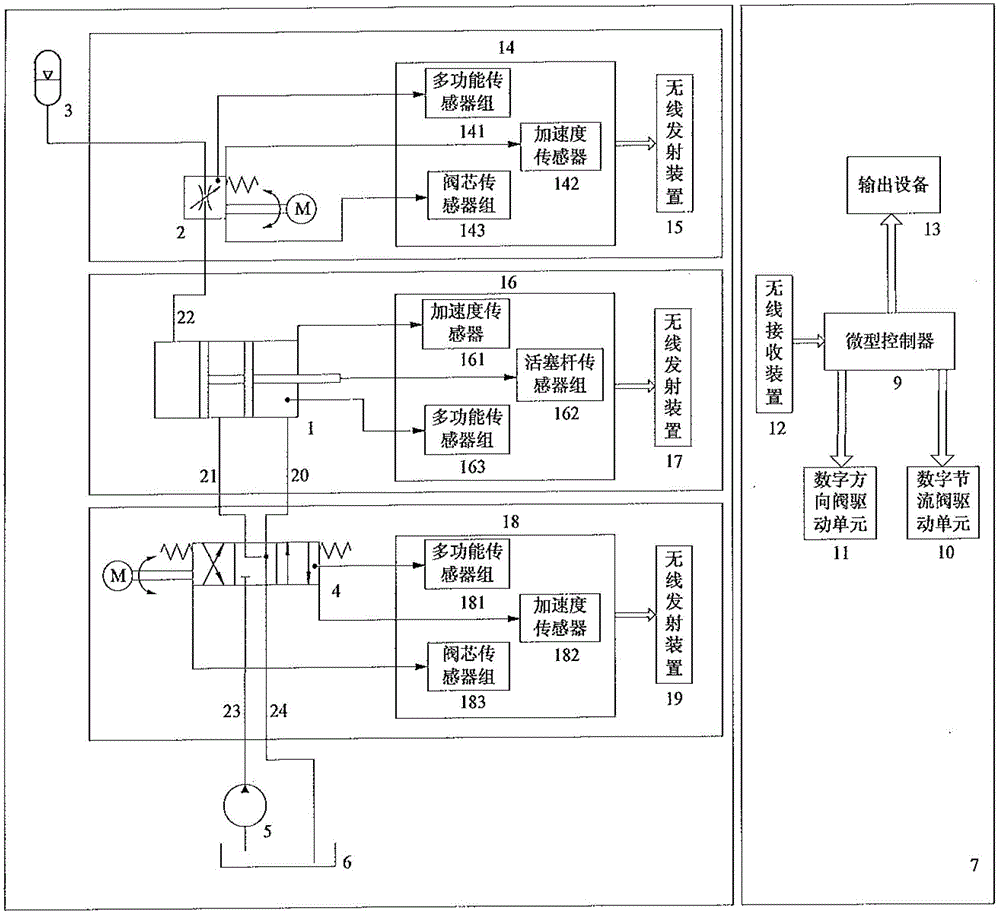

[0097] Embodiment 2 is the same as Embodiment 1, except that the suspension unit is in the active working mode, and each suspension unit is interconnected and controlled. The schematic diagram of the active interconnected suspension system is as follows Figure 6 As shown, the digital directional valve 104 is also shared at this time, and the controller outputs the digital directional valve 104 control signal:

[0098] The interconnection form realizes the interconnection between the hydraulic cylinders of each suspension unit by configuring the oil passages between the four suspension units, so that the oil passages of the compressed chambers are connected and the oil passages of the stretched chambers are connected. The oil passages are configured through a general electromagnetic Reversing valves 501, 502 and 503 are implemented. When the three-position and four-way electromagnetic reversing valve is in the neutral position, the valve ports are connected to each other. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com