A power system assembly of a two-speed electric vehicle

A power system and electric vehicle technology, applied in vehicle components, control devices, transportation and packaging, etc., can solve the problems of low motor work efficiency, affecting the space layout of the vehicle, increasing mechanical noise, vibration, etc., and achieves compact structure, Reduce the complexity and area, eliminate the effect of mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

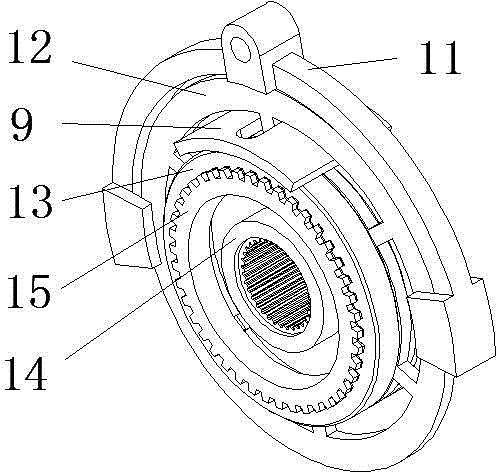

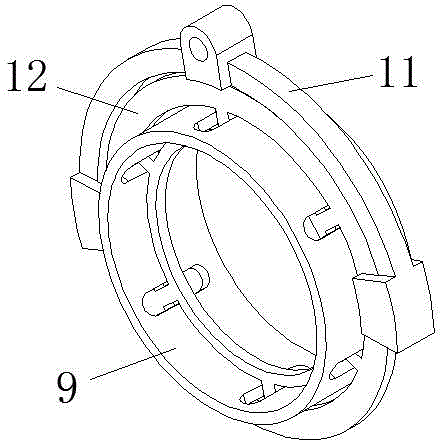

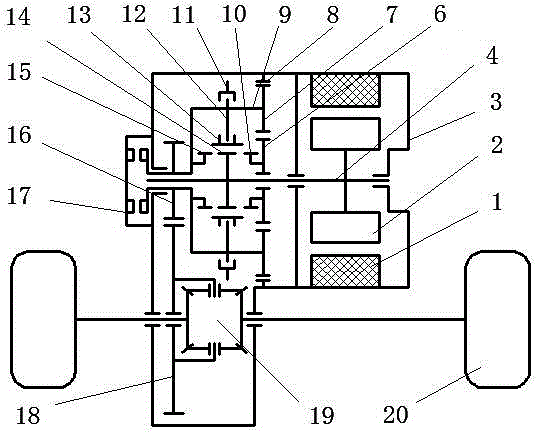

[0021] see figure 1 , a power system assembly of a two-speed electric vehicle includes an electric motor, a single-row planetary gear train, a synchronizer, a single-stage final reducer, a differential, an electromagnetic brake 17 and a housing 3 .

[0022] The stator 1 of the motor is fixedly installed in one side of the housing 3 , and the rotor 2 is connected to one side of the rotor shaft 4 . The other side of the rotor shaft 4 is installed through the bearing on the other side of the housing 3; the middle part of the rotor shaft 4 is provided with a central gear 6, and the meshing sleeve 14 on the synchronizer is fixedly installed. An inner ring gear 8 is fixedly mounted on the housing 3 corresponding to the central gear 6 . The other side of the rotor shaft 4 is provided with a planetary carrier 9, and one side of the planetary carrier 9 is equipped with three planetary gears 7, and the other side of the planetary carrier 9 is in the shape of a tube shaft, and the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com