Hot roller carrying device

A technology of handling device and hot roller, applied in the direction of lifting device, etc., can solve the problems of injury, inconvenience, low work efficiency, etc., and achieve the effect of convenient movement, saving man-hours, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

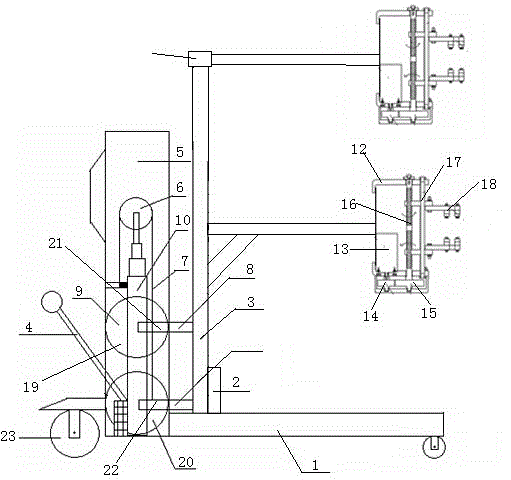

[0017] Such as figure 1 A heat roller handling device is shown, which is composed of a body body 1, a first motor 2, a column 3, a hydraulic lifting mechanism, and a heat roller clamping mechanism. , channel steel track 5, runner 6, chain 7, lifting rod 8, track wheel 9, hydraulic cylinder 10, gear 11, described hydraulic cylinder 10 is arranged in the channel steel track 5, and its top is provided with runner 6, The bottom end is fixedly installed on the vehicle body itself 1; one end of the chain 7 is fixed on the vehicle body 1, and the other end is connected to the elevating rod 8 around the runner 6, and one end of the elevating rod 8 is connected to the chain that moves up and down along the channel steel track 5. The center axis of the track wheel 9 is connected, and the other end is connected horizontally with the column 3; the hydraulic rod 4 is fixedly installed at the lower part of the hydraulic cylinder 10; the upper hot roller clamping mechanism connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com