Mechanical alloy plate panel surface strengthening device

A technology of mechanical strengthening and alloy plate, which is applied in the field of mechanical strengthening device and mechanical strengthening device of alloy plate surface, which can solve the problems of inability to strengthen, general effect, large equipment volume, etc., and achieve easy installation and disassembly, flexible use and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

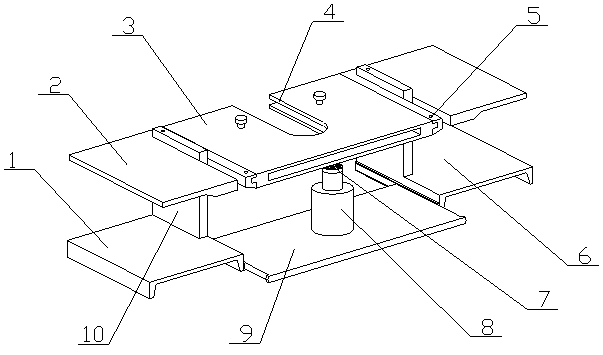

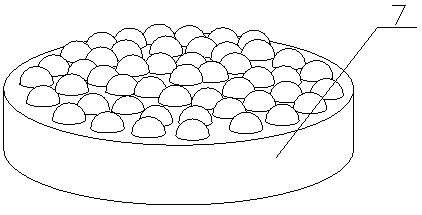

[0027] A mechanical strengthening device for the surface of an alloy plate in the present invention is realized in the following way: a mechanical strengthening device for the surface of an alloy plate in the present invention consists of a main base (1), a side fixing plate (2), a guide splint (3), and an impact groove ( 4), fixed screw (5), auxiliary base (6), impact head (7), impact cylinder (8), support plate (9) and vertical plate (10), the two main bases (1) are respectively placed The two ends of the supporting plate (9), the main base (1) is a plate-shaped structure, and both sides are respectively bent downwards, and the side of the main base (1) close to the supporting plate (9) has a chute , and stuck on the supporting plate (9), the chute extends from one end of the base to the other end, the two ends of the supporting plate (9) are respectively set with limit blocks near one side, and the impact cylinder (8) is placed In the middle of the supporting plate (9), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com