Rotary groove cutting device

A beveling device and rotary cutting technology, used in shearing devices, pipe shearing devices, accessories of shearing machines, etc., can solve the problems of inconvenient operation, low cutting efficiency, cumbersome structure, etc. The effect of slow cutting and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

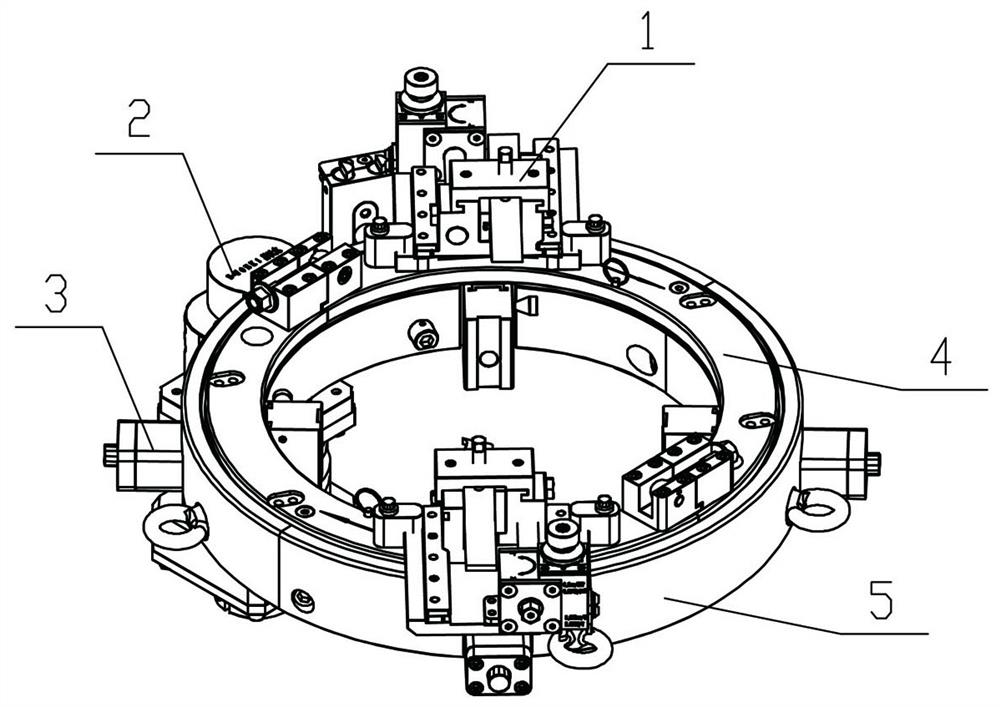

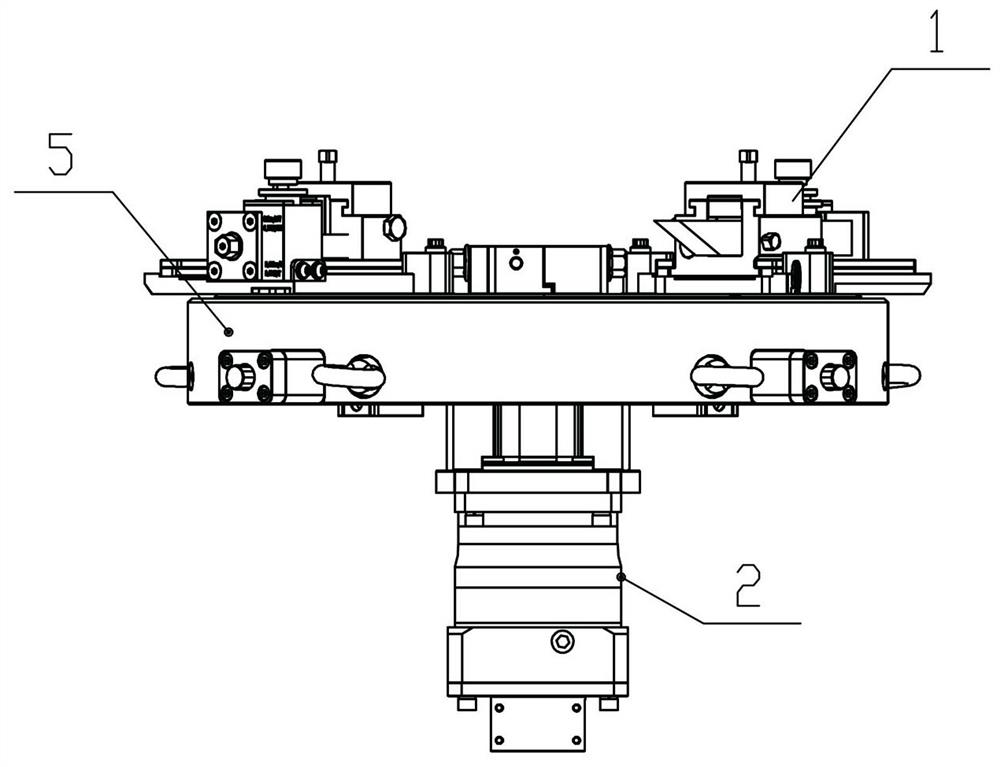

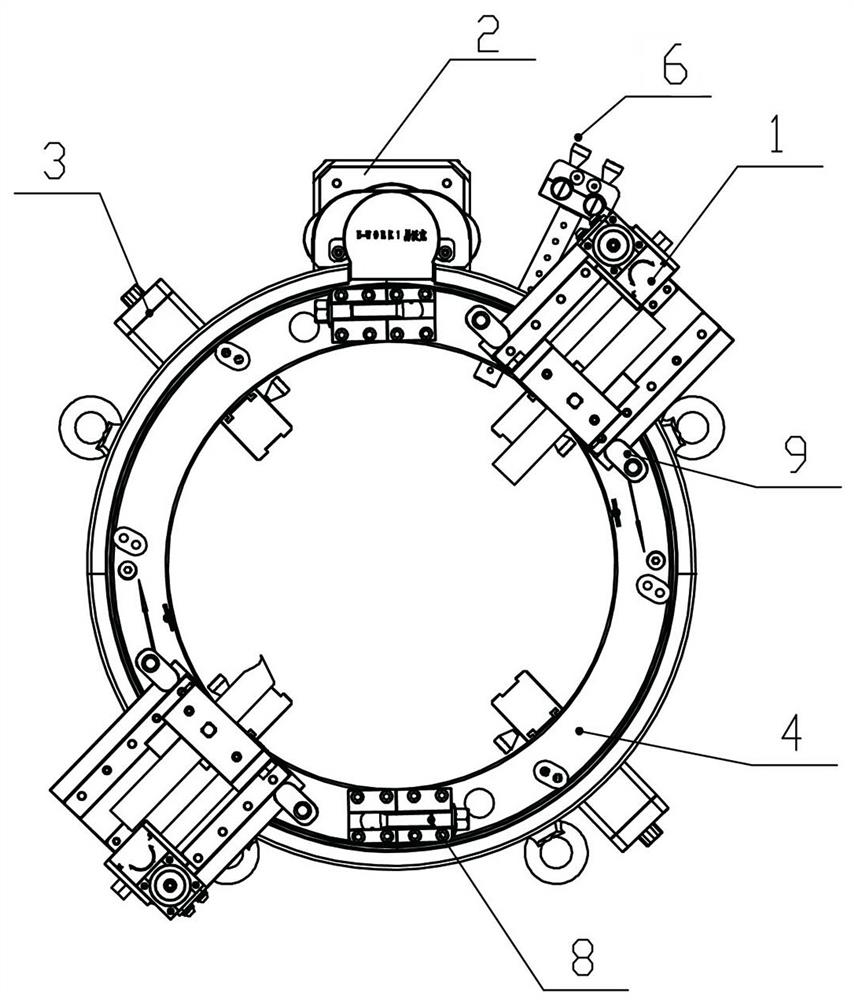

[0046]A rotary cutting beveling device, comprising a feed feed tool holder 1, a speed reduction mechanism 2, a lifting lug bolt 7, a rotation fixing device 8, a tool holder fixing plate 9, a telescopic leg 3, a moving coil device 4, a speed regulating feed The feeding device 6, the ring fixing device 5 and the supporting intelligent control system, the feed tool holder 1 includes a tool holder bottom plate 1-1, and the top side of the tool holder bottom plate 1-1 is provided with a sliding seat 1-6, and the sliding seat 1- 6 is a U-shaped groove structure, the top of the sliding seat 1-6 is provided with a sliding cover 1-4 for sliding connection, the sliding seat 1-6 is provided with a cutter 1-3, and the bottom of the cutter 1-3 passes through the first in the U-shaped groove. The tool holder backing plate 1-22 is fixed, the top of the tool 1-3 is fixed by the compression bolt 1-5 set in the slide cover 1-4, one side of the tool 1-3 is fixed to the side of the U-shaped groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com