Cold-rolled steel plate and preparation method thereof

A technology for cold-rolled steel plates and slabs, applied in the field of cold-rolled steel plates and their preparation, can solve the problems of large temperature difference and difficult process control, and achieve the effects of low cost, low process implementation difficulty and excellent market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

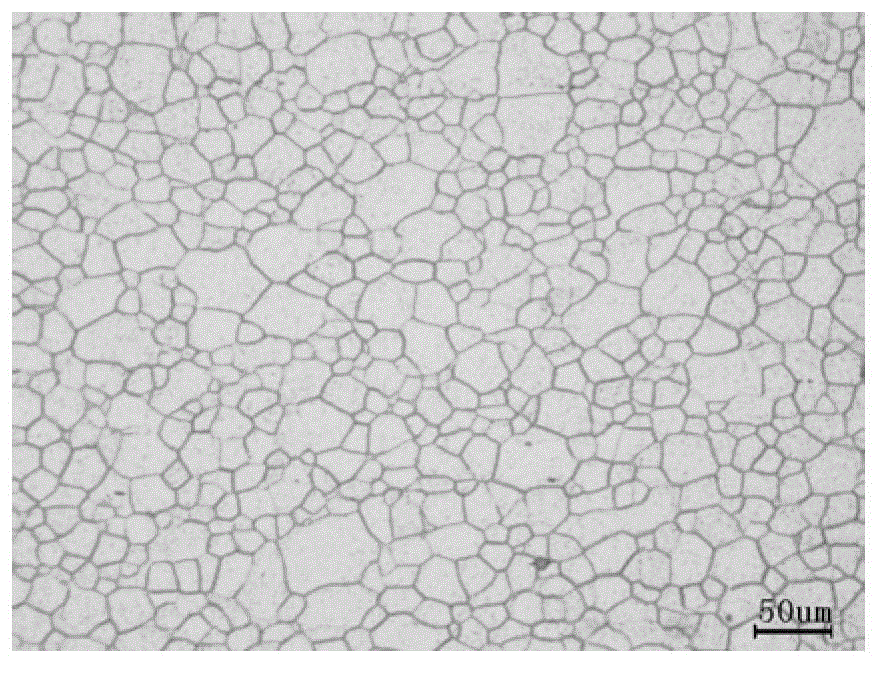

Image

Examples

preparation example Construction

[0012] The invention provides a method for preparing a cold-rolled steel plate. The method comprises: hot-rolling, coiling, cold-rolling, annealing and smoothing of the slab in sequence, wherein the temperature of the hot-rolling is 1100-1300°C, and the The finishing temperature of the hot rolling is 900-1000°C, and the thickness of the intermediate slab obtained after the hot rolling is 2.8-4.5 mm; after the hot rolling and before coiling, the intermediate slab obtained after the hot rolling is cooled to 700-850°C, the cooling rate of the cooling is 55-75°C / s; the coiling temperature is 730-770°C; the reduction rate of the cold rolling is 70-90%; the annealing temperature 800-900°C respectively, the annealing time is 50-70s; the flat elongation of the flat is 0.2-1%.

[0013] In the present invention, the slab can be selected according to production needs, for example, the slab can be a continuous casting slab. Preferably, the weight percent of the components of the slab is:...

Embodiment 1

[0030] This example is used to illustrate the preparation method of the cold-rolled steel plate provided by the present invention.

[0031] The slab is hot-rolled at 1199°C into a 4.0mm-thick intermediate slab, and the final rolling temperature of the hot rolling is 915°C; then cooled to 790°C at a cooling rate of 55°C / s, and then air-cooled for 14s; The coiling machine is coiled into coils, and the coiling temperature is 760°C; then cooled to room temperature (25°C), pickled with hydrochloric acid, and rolled into a cold-rolled sheet of 0.8mm at a reduction rate of 80% on a cold tandem rolling mill; and then Annealed on the continuous annealing unit, the annealing temperature is 850 ℃, the time is 65s; then it is flattened, and the flattened elongation is 0.49%. The mechanical property of the final cold-rolled steel plate is the yield strength R eL 135MPa, tensile strength R m 274MPa, elongation after break A 80 is 49.0%, the plastic strain ratio r 90 2.9, work hardening ...

Embodiment 2

[0034] This example is used to illustrate the preparation method of the cold-rolled steel plate provided by the present invention.

[0035] The slab is hot-rolled at 1100°C into a 3.0mm-thick intermediate slab, and the final rolling temperature of the hot rolling is 925°C; then cooled to 750°C at a cooling rate of 65°C / s, and then air-cooled for 12s; The coiling machine is coiled into coils, and the coiling temperature is 732°C; then cooled to room temperature (25°C), pickled with hydrochloric acid, and rolled into 0.8mm cold-rolled sheets at a reduction rate of 73% on a cold tandem rolling mill; and then Annealed on the continuous annealing unit, the annealing temperature is 868 ℃, the time is 55s; then it is flattened, and the flattened elongation is 0.68%. The mechanical property of the final cold-rolled steel plate is the yield strength R eL 143MPa, tensile strength Rm 285MPa, elongation after break A 80 is 47.5%, the plastic strain ratio r 90 2.8, work hardening expone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com