Cover-excavation construction method of composite wall of subway station and mobile side wall formwork trolley

A technology for subway stations and construction methods, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems affecting project progress, heavy workload, and long time consumption, and achieve reliable construction quality, improved construction quality, and simple operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

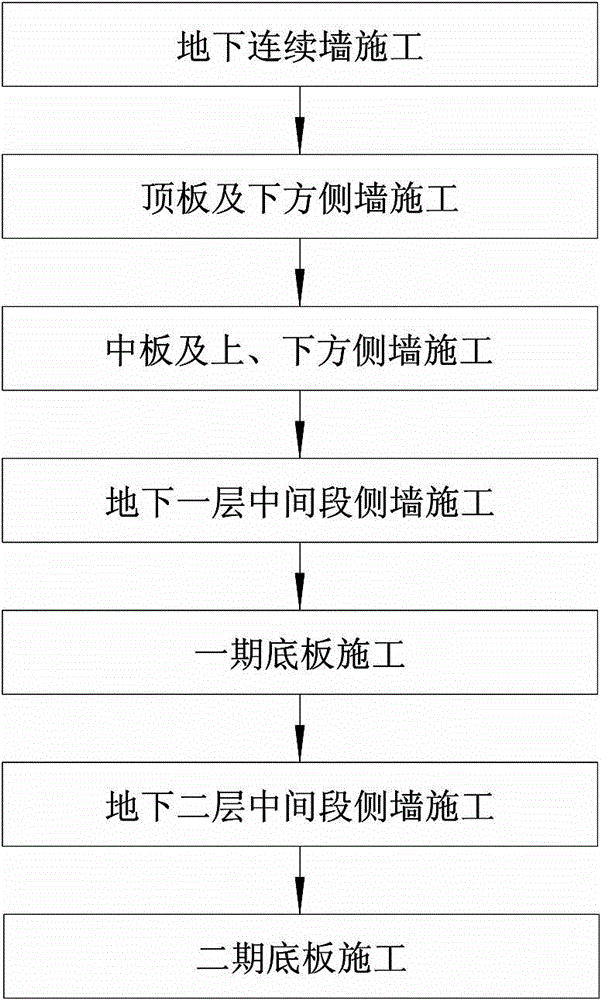

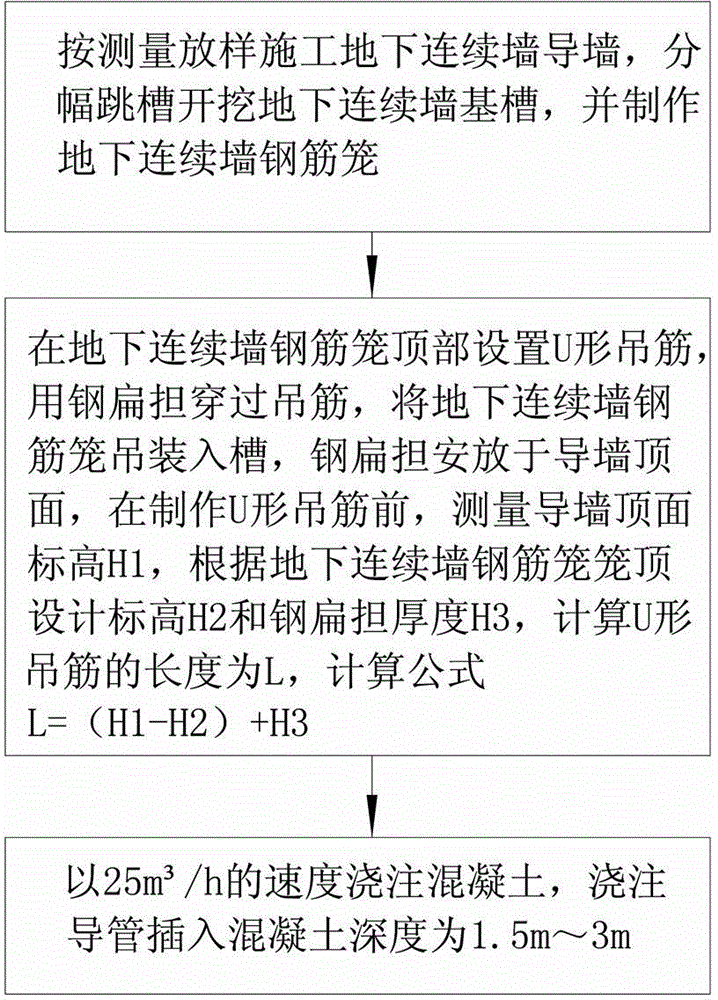

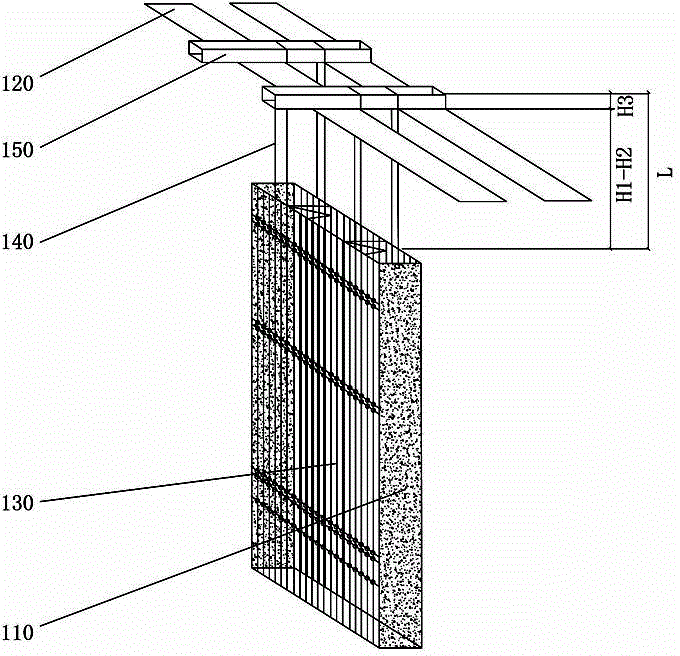

[0040] Figure 1 to Figure 4 Shown is an embodiment of the construction method for the superimposed wall of the subway station by cover and digging upside down according to the present invention. In the construction method of the superimposed wall of the subway station by cover and digging upside down in the present embodiment, the superimposed wall comprises a pair of underground continuous walls 100, which are designed For the top plate 200, the middle plate 300, the first-stage base plate 400 and the second-stage base plate 500 between a pair of underground diaphragm walls 100, and the side walls 600 arranged along the inside of a pair of underground diaphragm walls 100, the walls and plates are as follows Step construction:

[0041] S1: Construction of underground diaphragm wall 100;

[0042] S2: Construction of the roof 200 and the side wall 610 below the roof: chiseling and cleaning of the underground diaphragm wall 100: Excavate the foundation pit of the roof and the 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com