Distributed variable-frequency control system

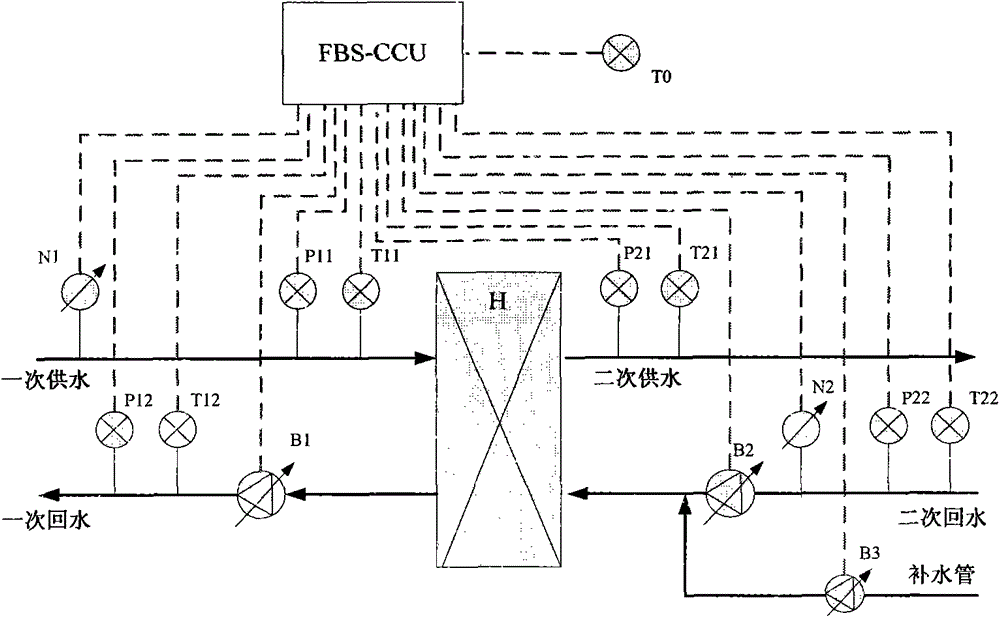

A frequency conversion control, distributed technology, applied in heating systems, heating methods, household heating and other directions, can solve problems such as hydraulic imbalance, excessive capital use of pressure head, uneven heating and cooling of heating systems, etc., to save thermal energy, It is convenient for remote monitoring and the effect of reducing the lift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

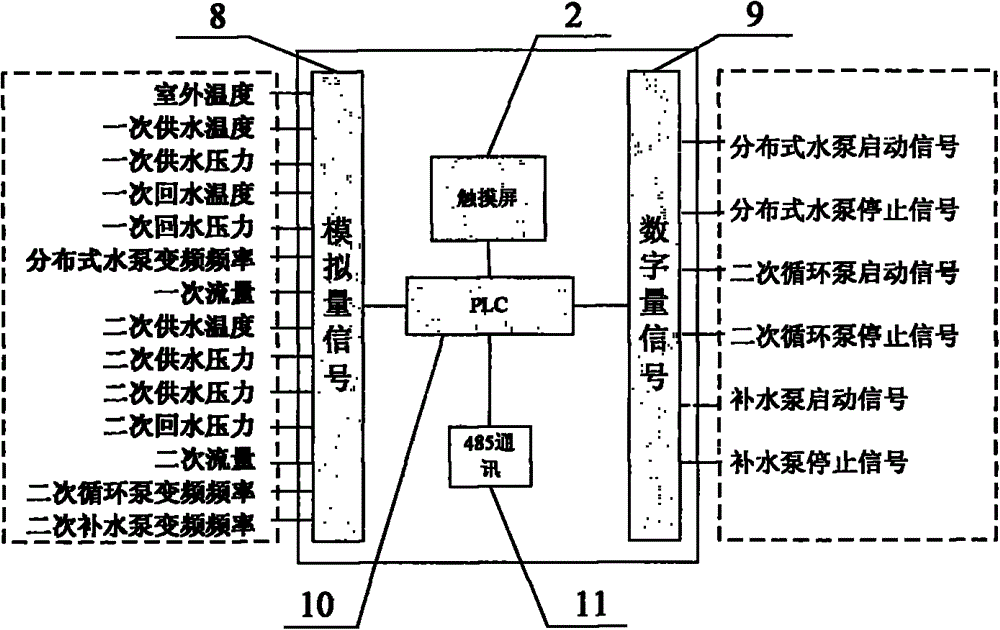

[0018] The invention consists of five parts, liquid crystal touch screen (2), controller PLC (10), analog signal module (8), digital signal module (9) and 485 communication module (11).

[0019] In the present invention, after the start of power-on, the controller PLC (10) is first initialized, then the analog signal module (8) is initialized, the digital signal module (9) is initialized, and the working parameters are set through the touch key keyboard of the liquid crystal touch screen (2), Then check the signals collected by the analog signal module (8) and the digital signal module (9), return abnormally, and continue the operation of the control program normally. The control acquisition is displayed through the liquid crystal touch screen (2), and for the controlled equipment, through the compensation control function and the PID control algorithm calculation of the control software of the present invention, the parameters set by the analog signal module (8) and the touch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com