Online fault detecting system and method for magnetron

A fault detection and magnetron technology, applied in the field of magnetron working state detection system, can solve problems such as inability to deal with complex faults in the industrial field and single detection physical quantity, so as to improve reliability and completeness, improve working environment, and ensure The effect of real-time and correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] specific implementation plan

[0042] The preferred examples of the present invention are given below to further illustrate the present invention, but not to limit the present invention.

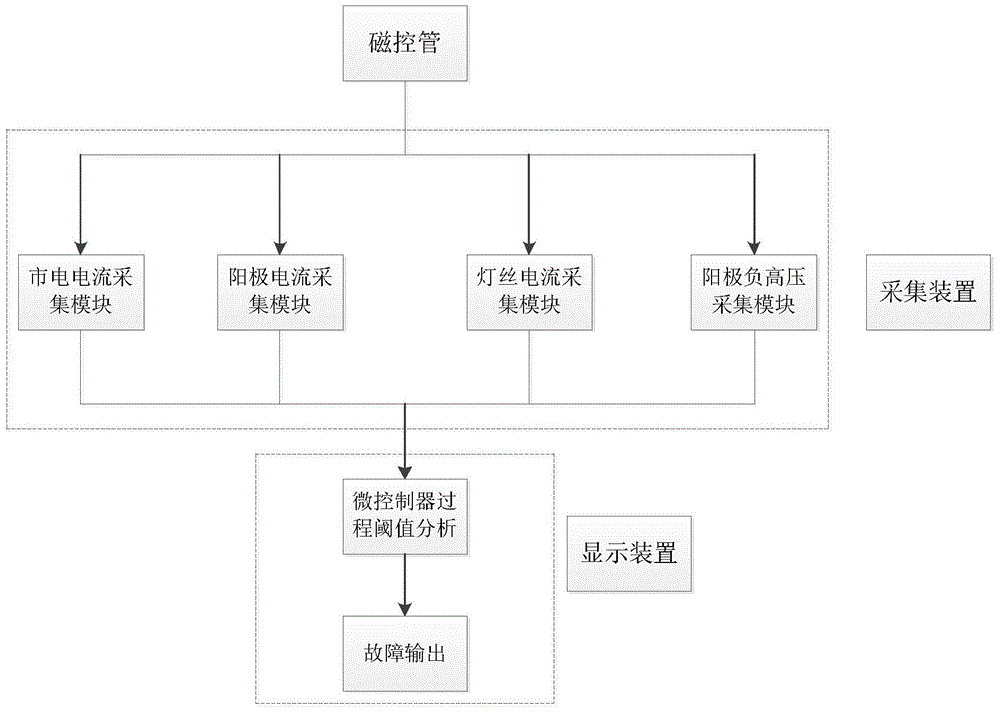

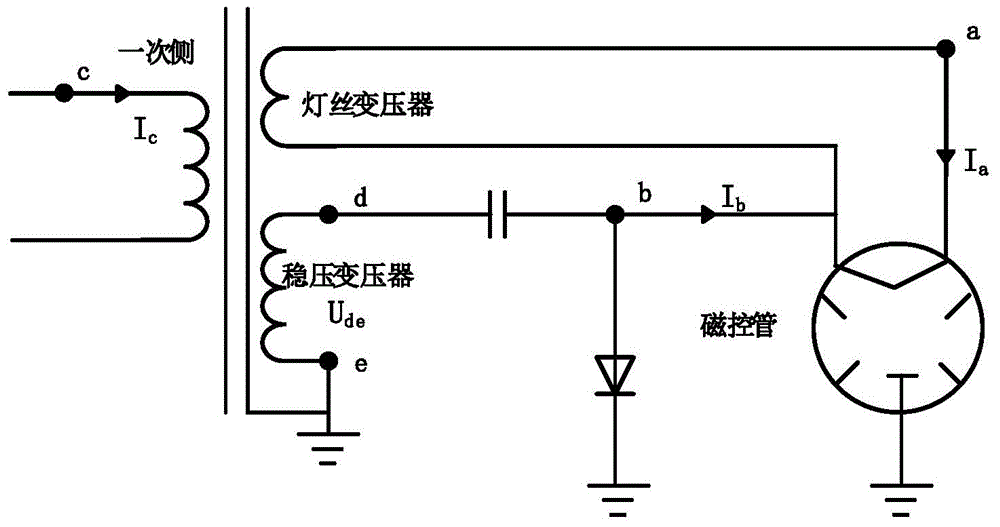

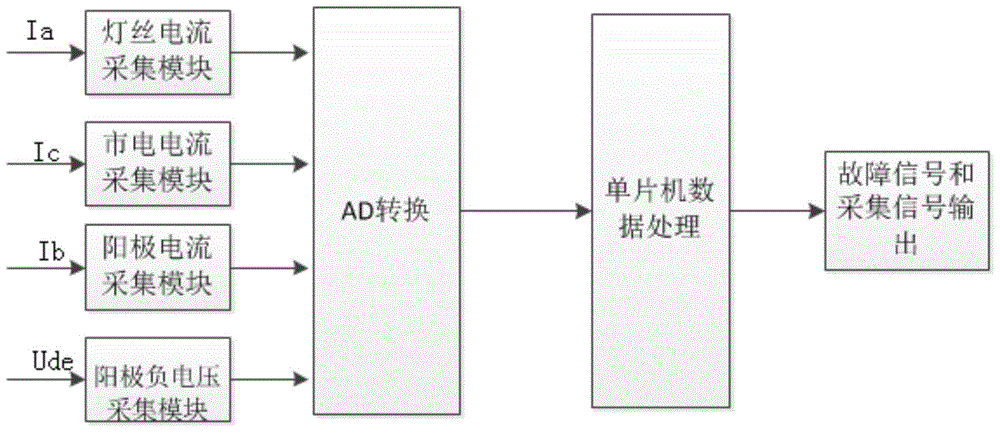

[0043] as attached Figure 1-4 As shown, the present invention relates to a magnetron online fault detection system, comprising a magnetron working circuit, a collection device connected to the magnetron working circuit, and a display device connected to the collection device; the collection device includes an integrated On a circuit board and work independently to collect the filament current I a , mains current I c , anode negative high voltage U de , anode current I b The filament current I a Acquisition module, mains current I c Acquisition module, anode negative high voltage U de Acquisition module, anode current I b An acquisition module and a single-chip microcomputer for analog-to-digital conversion and data processing; the display device is used to receive the collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com