Thin-film transistor array base plate, display panel and display device

A technology for thin film transistors and array substrates, applied in the display field, can solve the problems of photoresist material isolation columns easily sliding into PLN holes, low cell thickness, and alignment film scratches, etc., so as to improve display quality, improve inversion effect, and improve The effect of surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

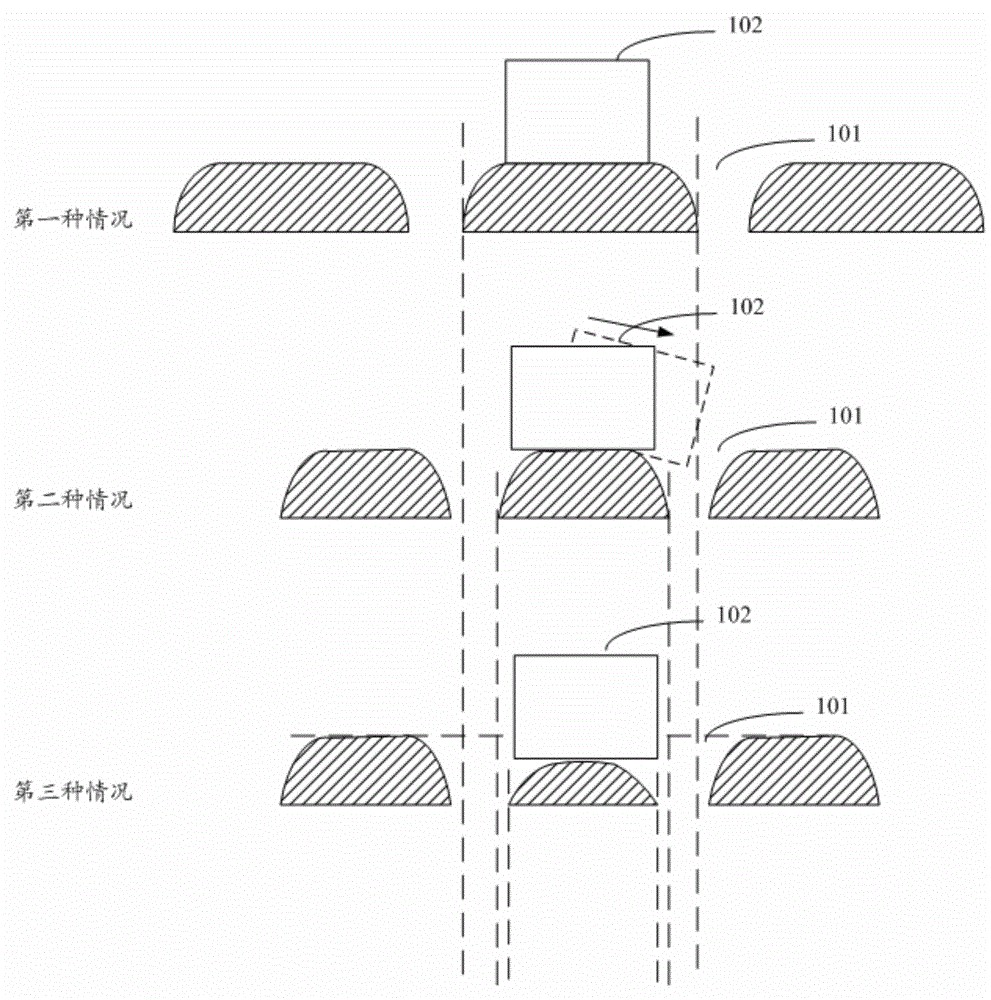

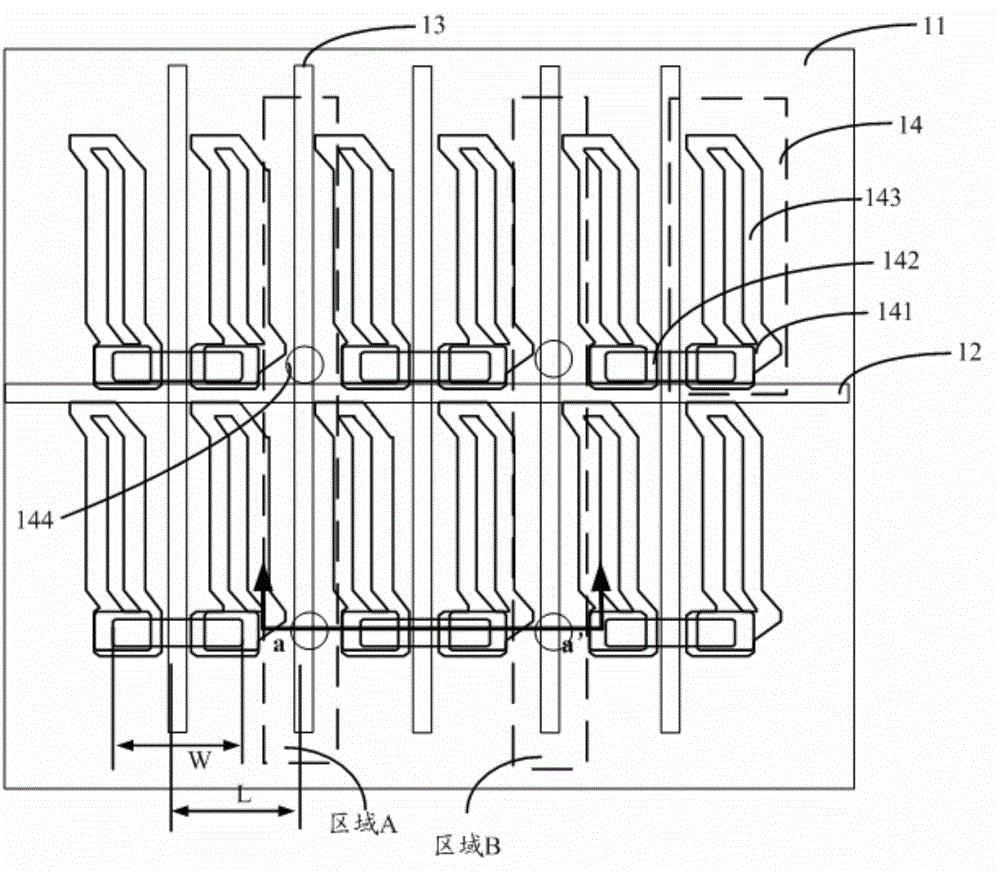

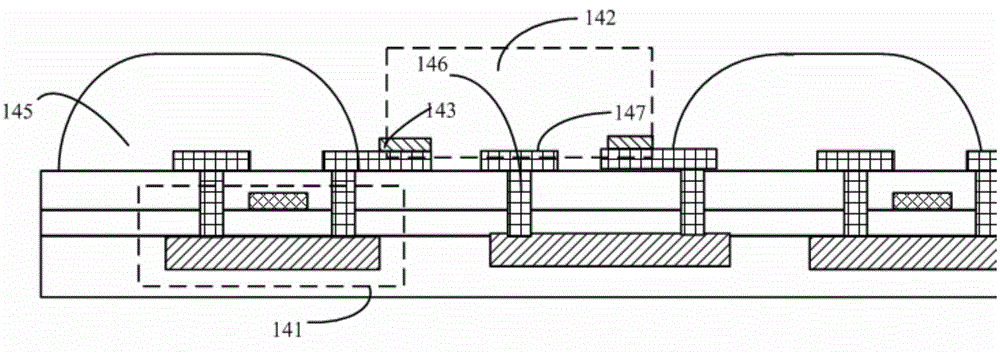

[0046] When reducing the size of each pixel unit in order to increase the pixel display density of the LCD, due to process limitations, the through hole needs to maintain the original size, such as figure 1 shown in the second case. At this time, due to the short distance between the adjacent through holes 101, when the through holes are formed by etching, an arc will appear at the supporting position where the spacer column 102 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com