A method suitable for upgrading the parameters of the whole production process of inertial measurement unit

An inertial measurement unit and production process technology, applied in measurement devices, program control devices, electrical digital data processing, etc., to reduce the risk of errors, improve production efficiency, and be easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

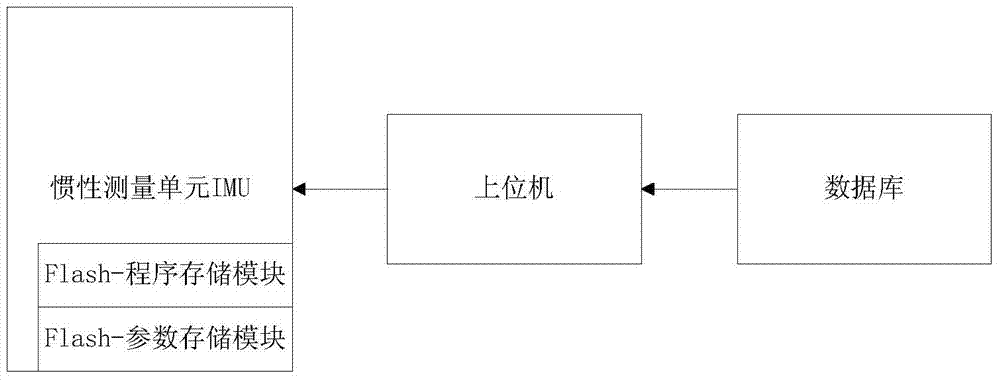

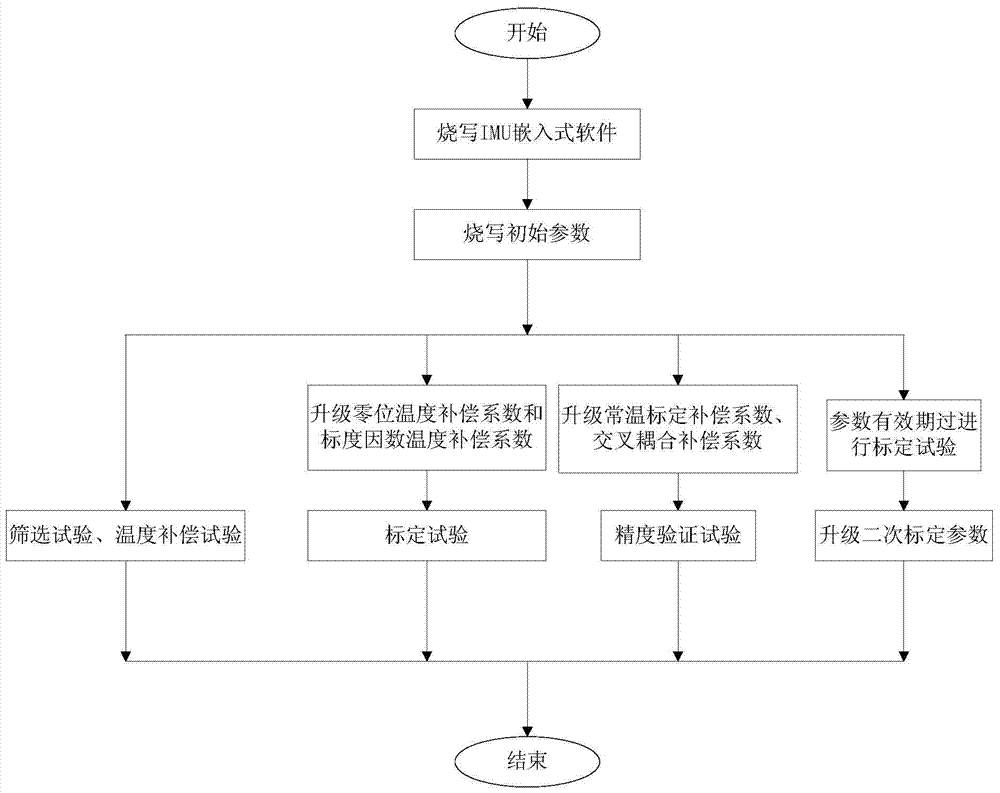

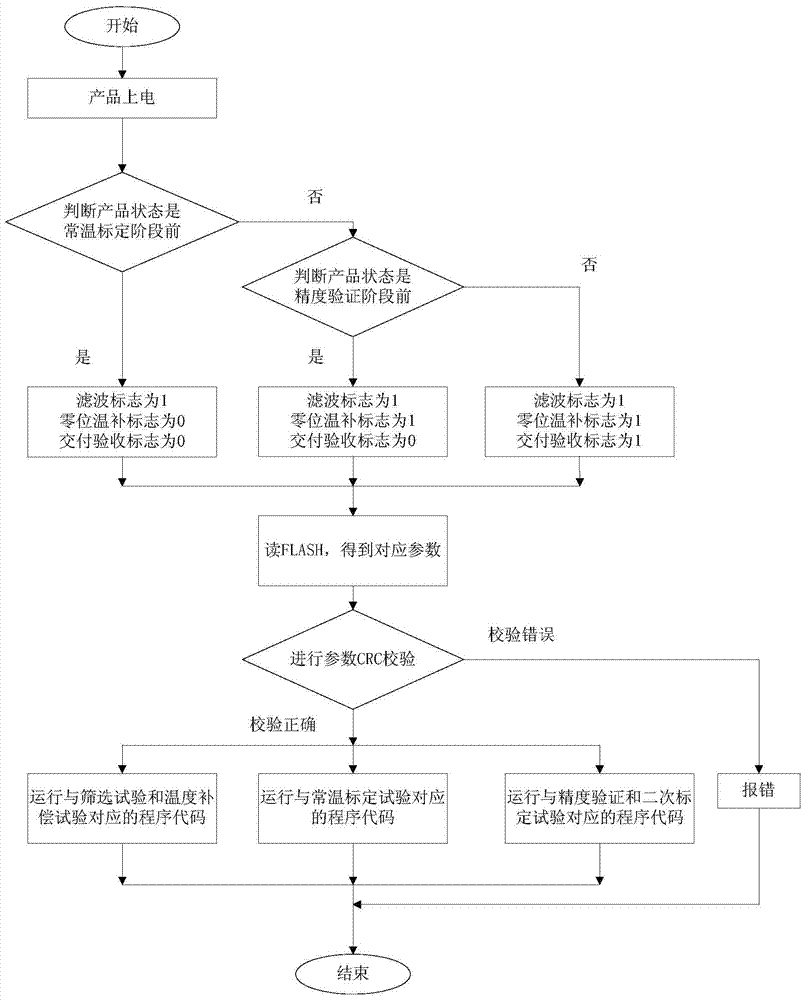

[0027] The method suitable for upgrading the parameters of the inertial measurement unit without opening the cover during the whole production process is used to upgrade the parameters of the inertial measurement unit during the production process, and its purpose is to upgrade the parameters of the inertial measurement unit reliably and efficiently. The characteristics of the present invention are: 1. Adopting the arrangement method of separating embedded programs and parameters, avoiding upgrading embedded programs when upgrading parameters, and reducing the risk of errors caused by manually modifying programs; 2. Using the host computer to read products in the database Parameters, automatically generate a binary parameter file, communicate with the inertial measurement unit, and burn it into the Flash address specified by the inertial measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com