Solar energy battery resisting potential-induced attenuation and manufacture method thereof

A technology of solar cells and potential-induced attenuation, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of low electrical performance and lower electrical performance parameters of photovoltaic modules, achieve superior electrical insulation characteristics, improve electrical performance, and be good The effect of electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

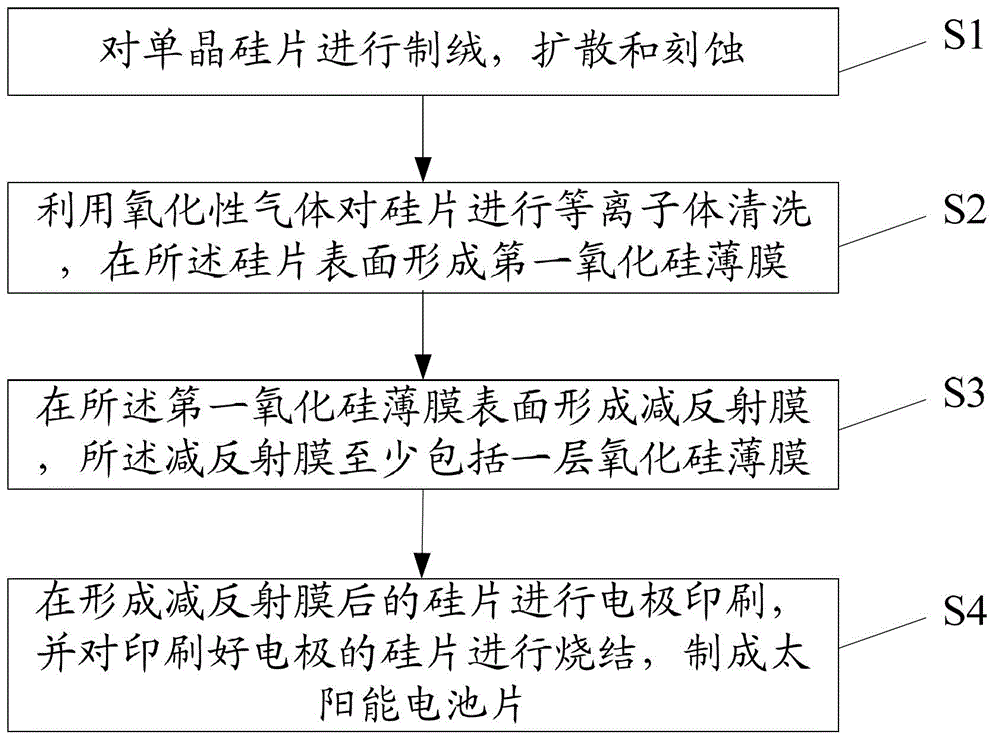

[0038] Such as figure 1 As described above, the embodiment of the present invention provides a method for manufacturing a solar cell, including:

[0039] Step S1: performing texturing, diffusion and etching on the monocrystalline silicon wafer. It should be noted that the single crystal silicon wafer may be a P-type single crystal silicon wafer or an N-type single crystal silicon wafer, which is not limited in the present invention. In the embodiment of the invention, the manufacturing method of the solar cell provided by the present invention is introduced in detail by taking the single crystal silicon wafer as an example of a P-type single crystal silicon wafer. Therefore, in one embodiment of the present invention, said performing texturing, diffusion and etching on the single crystal silicon wafer specifically includes: performing acid texturing, phosphorus diffusion and etching on the P-type single crystal silicon wafer.

[0040] Step S2: Plasma cleaning the silicon waf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com