Package substrate and manufacturing method thereof, and substrate assembly

A technology for encapsulating substrates and manufacturing methods, which is applied in the direction of printed circuits, electrical components, and circuit devices connected to non-printed electrical components, to achieve the effects of reliable structure, low manufacturing cost, and reduced failure risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

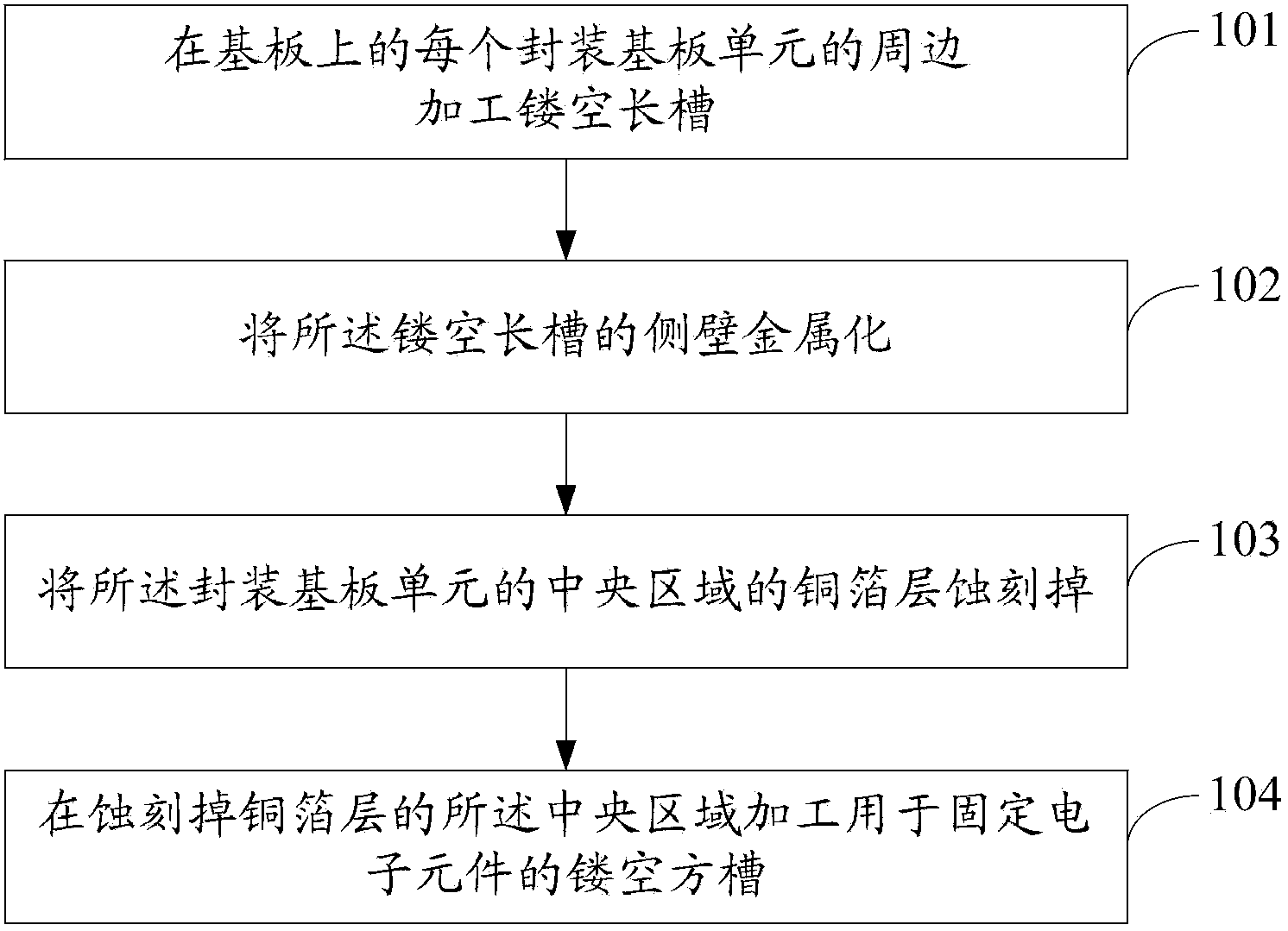

[0021] Please refer to figure 1 , an embodiment of the present invention provides a method for manufacturing a packaging substrate, including:

[0022] 101. Process hollow long grooves on the periphery of each packaging substrate unit on the substrate.

[0023] In this embodiment, the processing of the packaging substrate unit starts from a larger substrate, such as a double-sided copper-clad laminate. Several regularly arranged packaging substrate units are planned on the larger substrate. The plurality of packaging substrate units are arranged in an array, horizontally in rows and vertically in columns.

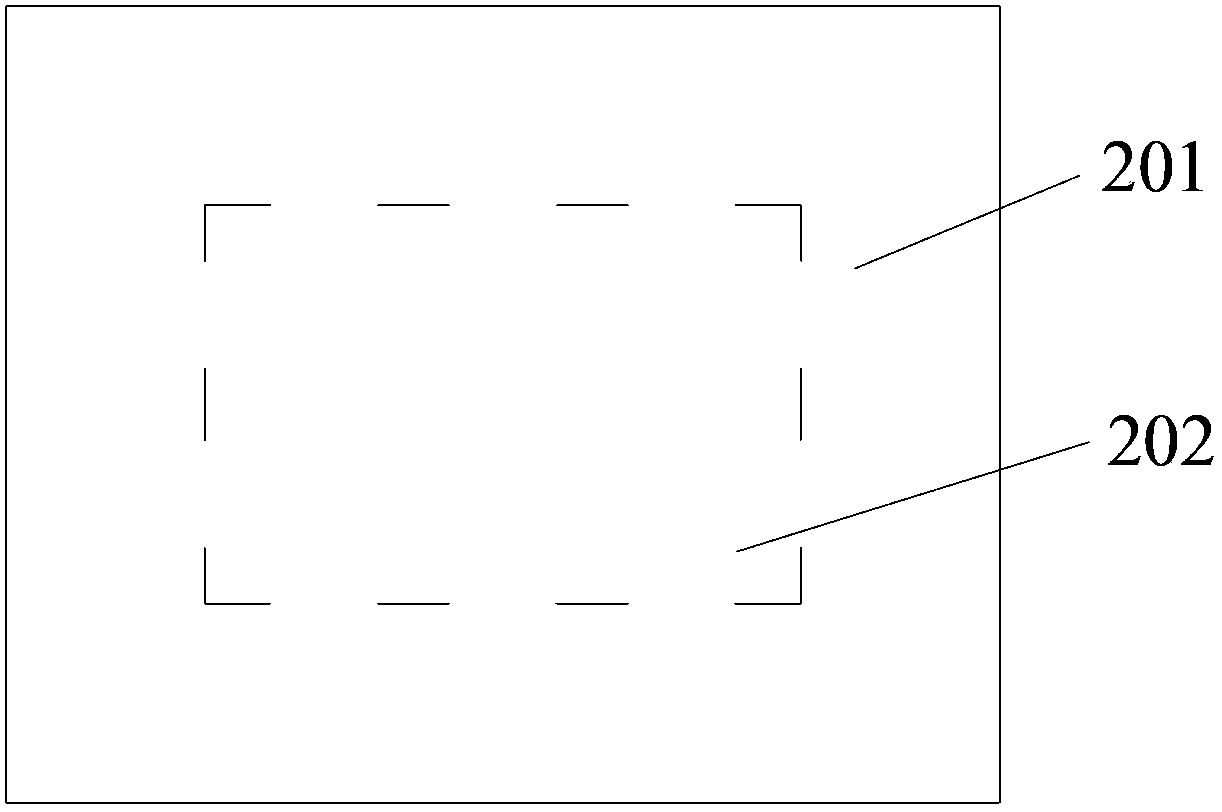

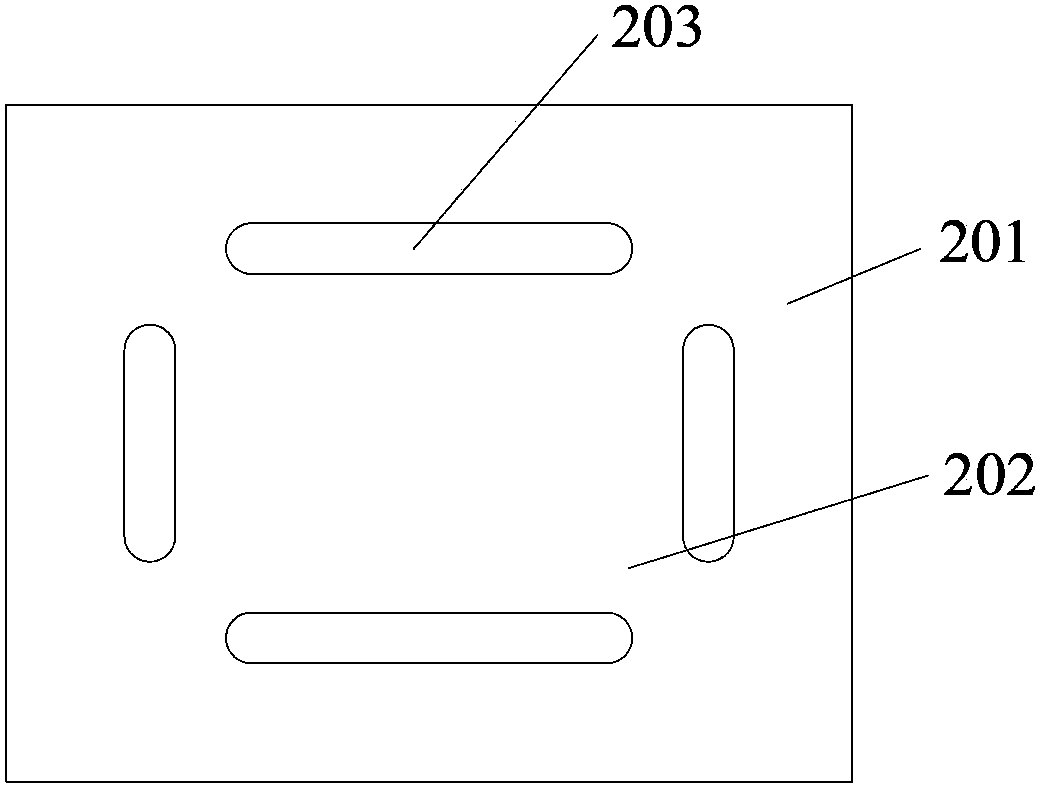

[0024] figure 2 A package substrate unit 202 on the substrate 201 is shown, and the dotted line box in the figure is the boundary of the package substrate unit 202 . In this step, if image 3 As shown, the hollow long grooves 203 can be processed along the dotted square frame on the periphery of the package substrate unit 202 , specifically, four hollow long grooves 2...

Embodiment 2

[0039] Please refer to Figure 10 The embodiment of the present invention provides a packaging substrate unit 202, the central area of the packaging substrate unit 202 is provided with a hollowed out square groove 209 for fixing electronic components, and the surrounding side walls of the packaging substrate unit 202 are processed for The metallization layer 205 for electromagnetic shielding of the electronic components.

other Embodiment approach

[0040]In other implementation manners, the four corner portions of the packaging substrate unit 202 may be respectively processed with metallized through holes 204 . A layer of nickel-gold or nickel-palladium-gold may be plated on the copper foil layer on the sealing-rotation substrate unit 202 and the surrounding sidewalls.

[0041] Please refer to Figure 11 , the embodiment of the present invention also provides a substrate assembly, including: the packaging substrate unit 202 as described above, the electronic components 301 embedded in the hollow square grooves opened by the packaging substrate unit 202, and respectively press-fitted on the packaging substrate unit 202. The upper and lower substrates 302 on both sides of the packaging substrate unit 202 are packaged, and the electronic components 301 are electrically connected to the circuit patterns on the upper substrate or the lower substrate.

[0042] As above, the embodiment of the present invention provides a packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com