Shell mould for manufacturing aircraft turbomachine bladed elements using the lost-wax moulding technique and comprising screens that form heat accumulators

A lost-wax casting and turbine unit technology, used in manufacturing tools, casting molding equipment, casting mold components, etc., can solve problems such as non-reach, and achieve the effects of reduced shrinkage, good fluidity, and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

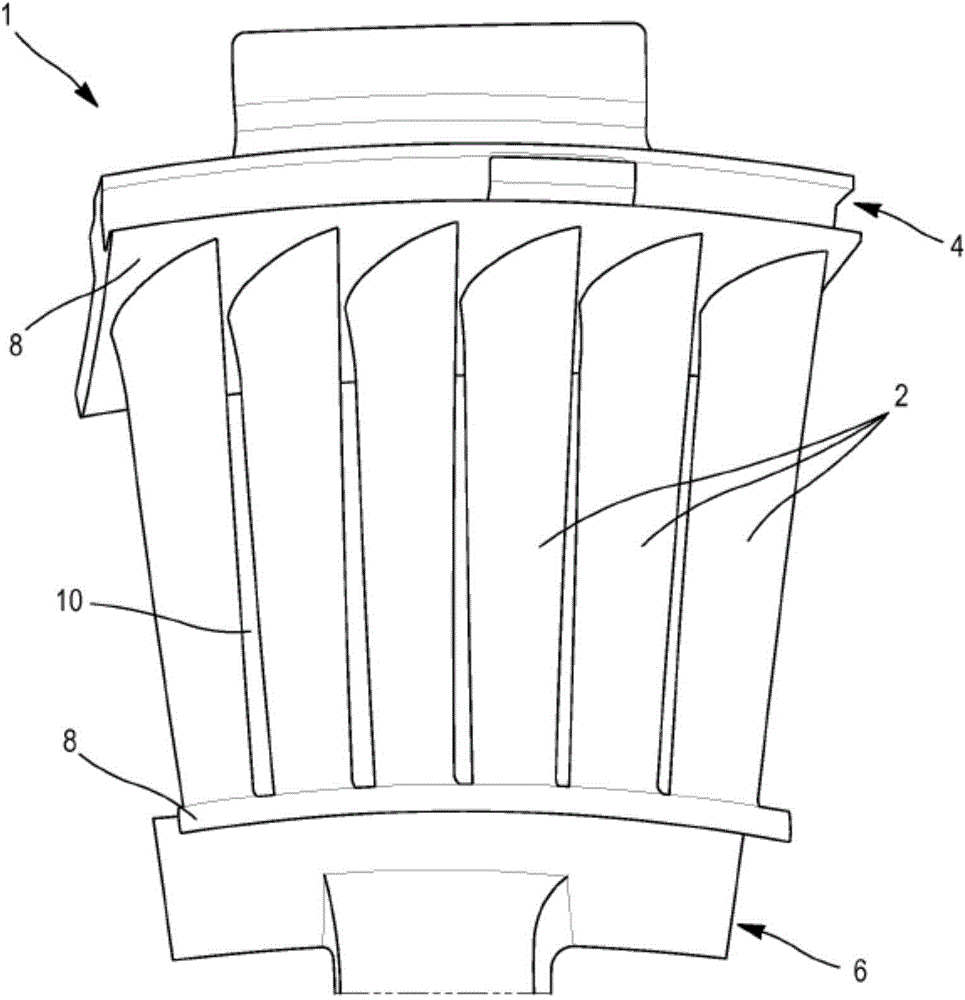

[0075] Referring to Figure 1 , there is shown a sector 1 of a turbine low pressure supply for an aircraft turbomachine. The sector comprises a plurality of blades 2 arranged between a first end 4 and a second end 6 . The two ends 4, 6 form outer and inner coronal sectors, respectively, and each comprise a platform 8 which delimits a main airflow 10 of the airflow. In addition to the platform 8 for additional aerodynamic functions, each end also includes a conventional structure that allows the bladed member to be mounted on the turbomachine model.

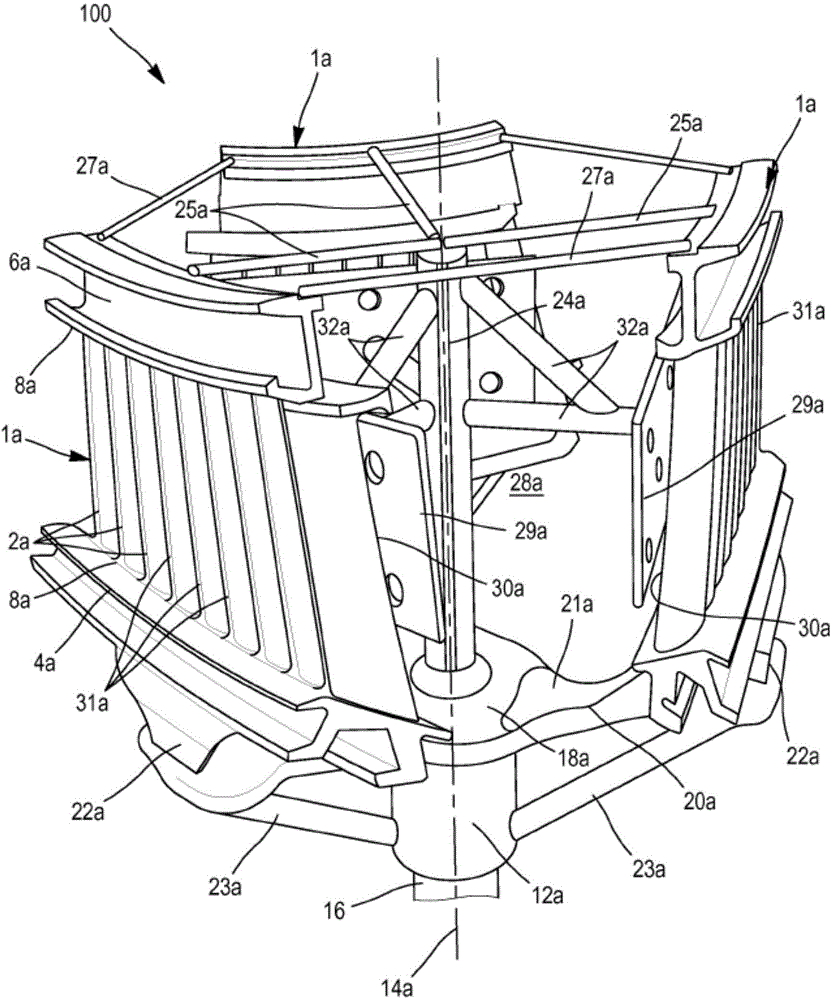

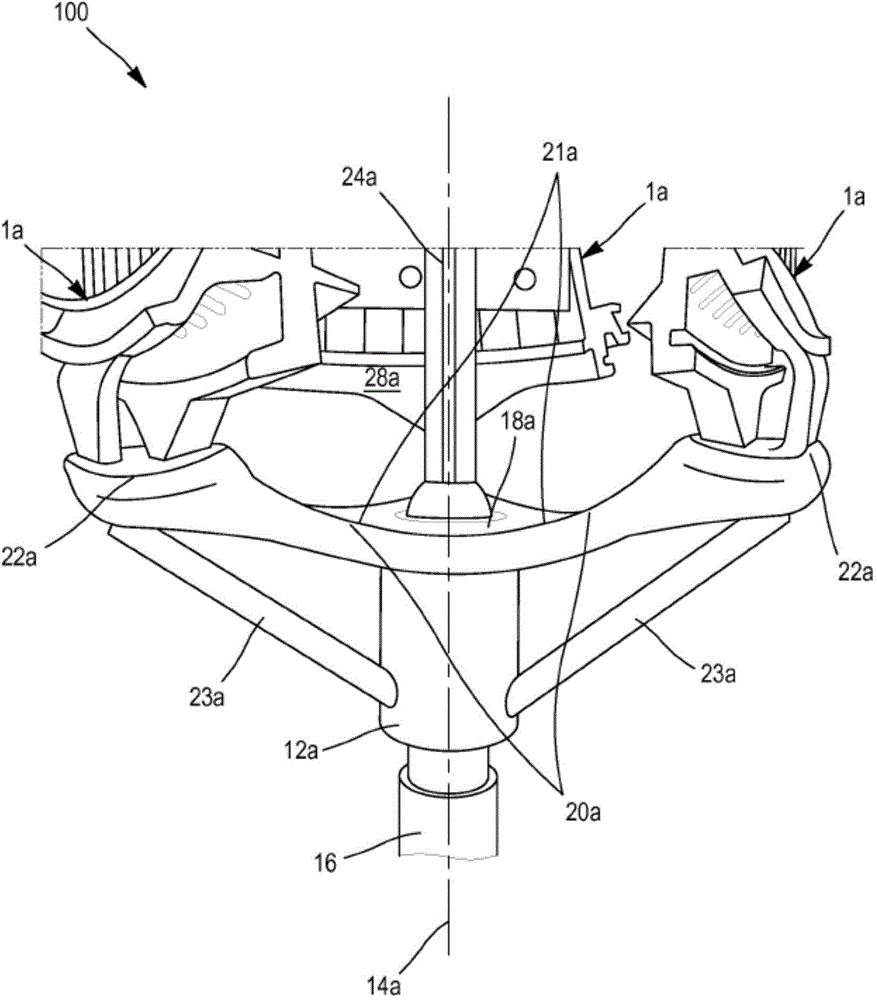

[0076] The object of the present invention is to manufacture a feeder sector 1 by the method of lost wax casting, a preferred embodiment of which will now be described with reference to FIGS. 2 to 6 .

[0077] First, a model, also called a replica, is made of wax, around which the ceramic shell mold that is intended to be formed later is made.

[0078] In FIGS. 2 to 4 , the model 100 is shown in a reversed position relative to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com