Polycrystalline silicon rod carrying tool, and polycrystalline silicon rod retrieval method

A technology of polysilicon rods and fixtures, applied in chemical instruments and methods, silicon, silicon compounds, etc., can solve problems such as difficulties, collapses, and dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

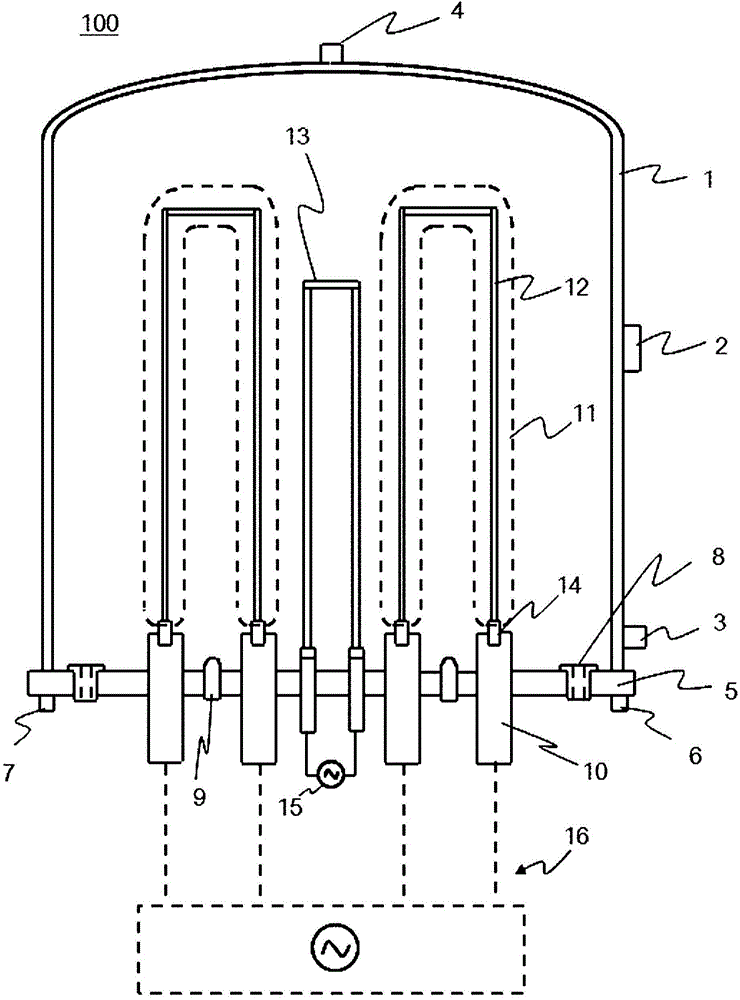

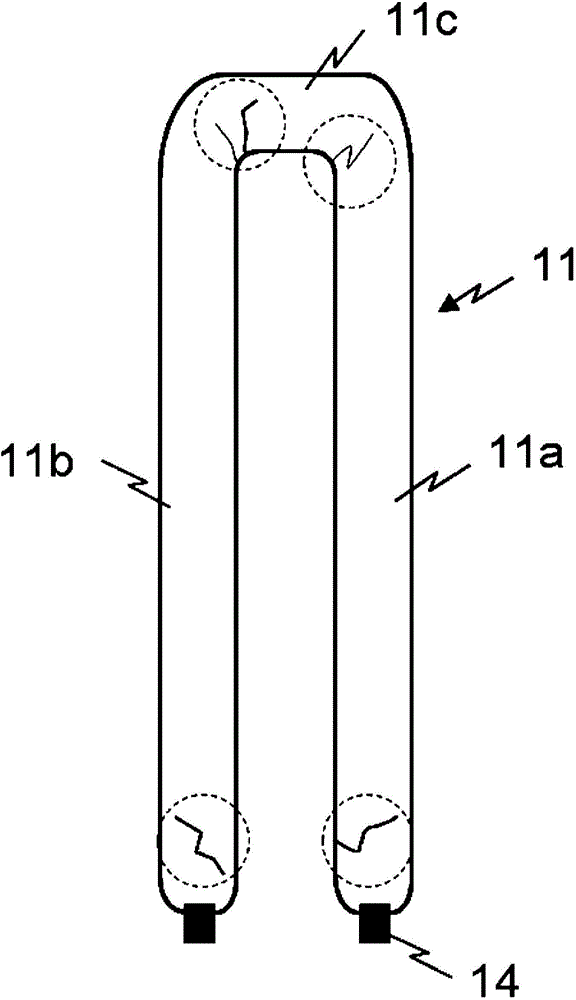

[0040] figure 1 It is a cross-sectional schematic explanatory diagram showing an example of the structure of the reaction furnace 100 when producing polycrystalline silicon rods according to the present invention. The reaction furnace 100 is a device for obtaining polycrystalline silicon rods 11 by vapor-phase-growing polycrystalline silicon on the surface of a silicon core wire 12 by the Siemens method, and is composed of a substrate 5 and a bell jar 1 .

[0041] Arranged on the substrate 5 are: a metal electrode 10 for supplying current to the silicon core wire 12; a gas nozzle 9 for supplying process gases such as nitrogen, hydrogen, and trichlorosilane gas; and a reaction waste gas outlet 8 for discharging waste gas.

[0042] The bell jar 1 is provided with a refrigerant inlet 3 and a refrigerant outlet 4 for cooling the bell jar 1 , and a viewing window 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com