Method of forming conformal metal silicide films

一种金属硅化物、金属硅化物层的技术,应用在金属材料涂层工艺、气态化学镀覆、涂层等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

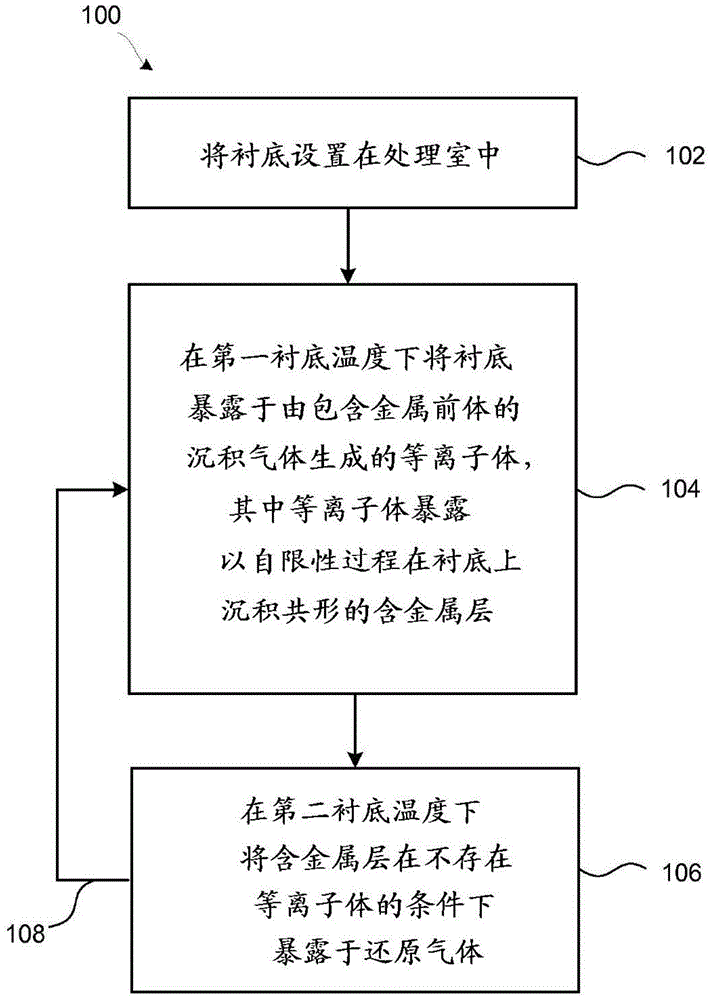

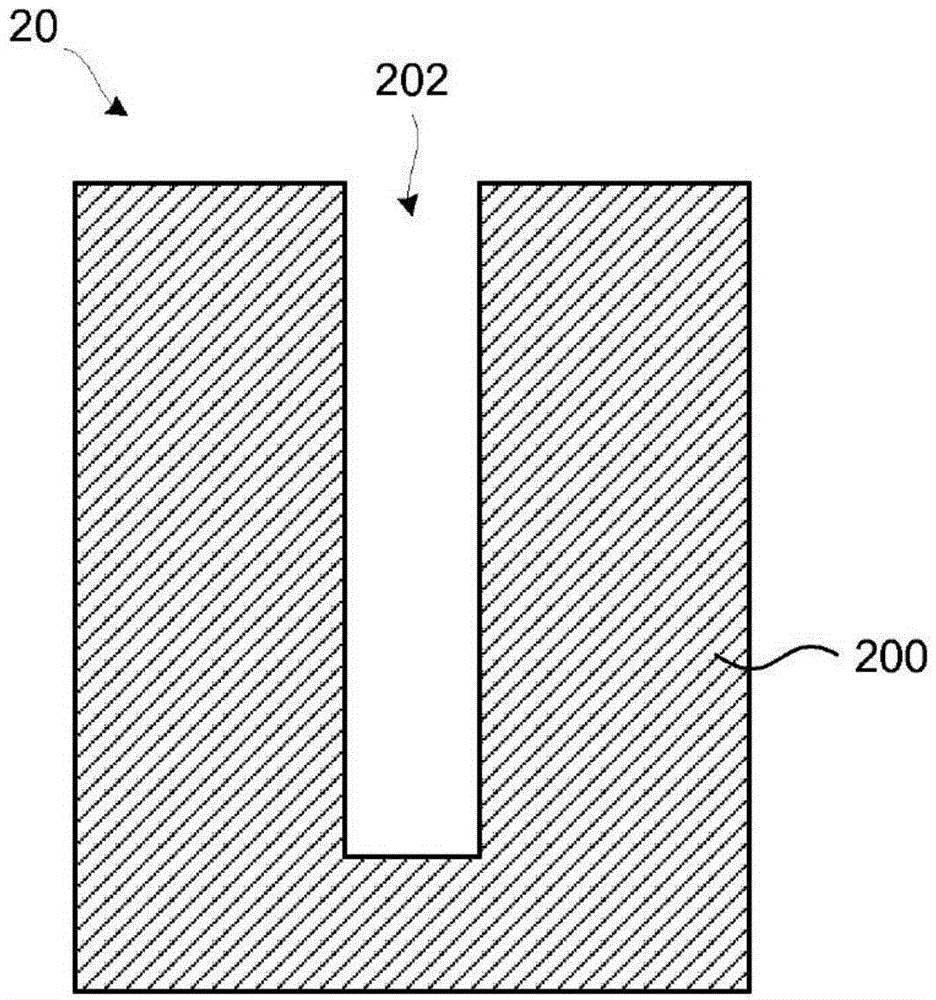

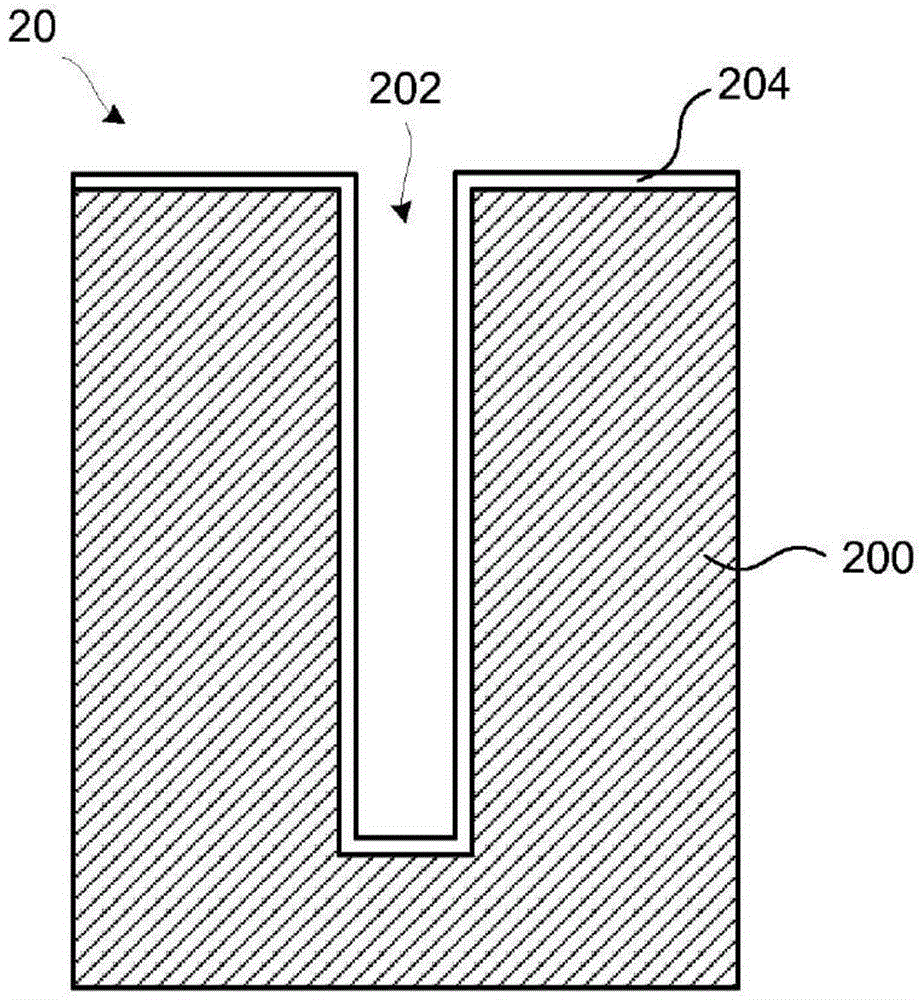

[0018] Methods for forming a conformal metal suicide layer on a substrate are disclosed in various embodiments. The metal silicide layer may, for example, comprise titanium silicide (e.g. TiSi x ), molybdenum silicide (such as MoSi x ), tungsten silicide (WSi x ), tantalum silicide (such as TaSi x ), or vanadium silicide (VSi x ), or a combination of two or more of them.

[0019] Those skilled in the relevant art will appreciate that the various embodiments may be practiced without one or more of the specific details, or may be practiced with other alternatives and / or additional methods, materials, or components. In other instances, well-known structures, materials, or operations are not shown or described in detail to avoid obscuring aspects of various embodiments of the invention. Also, for purposes of illustration, specific numbers, materials and configurations are set forth in order to provide a thorough understanding of the invention. Furthermore, it should be under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com