Potato chip flavoring machine

A technology of seasoning machine and potato chips, which is applied in food mechanical processing, food preparation, food forming, etc. It can solve the problems of affecting the appearance and taste of finished products, high work intensity, and manpower consumption, so as to reduce labor costs and labor intensity. Achieve mechanized production and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

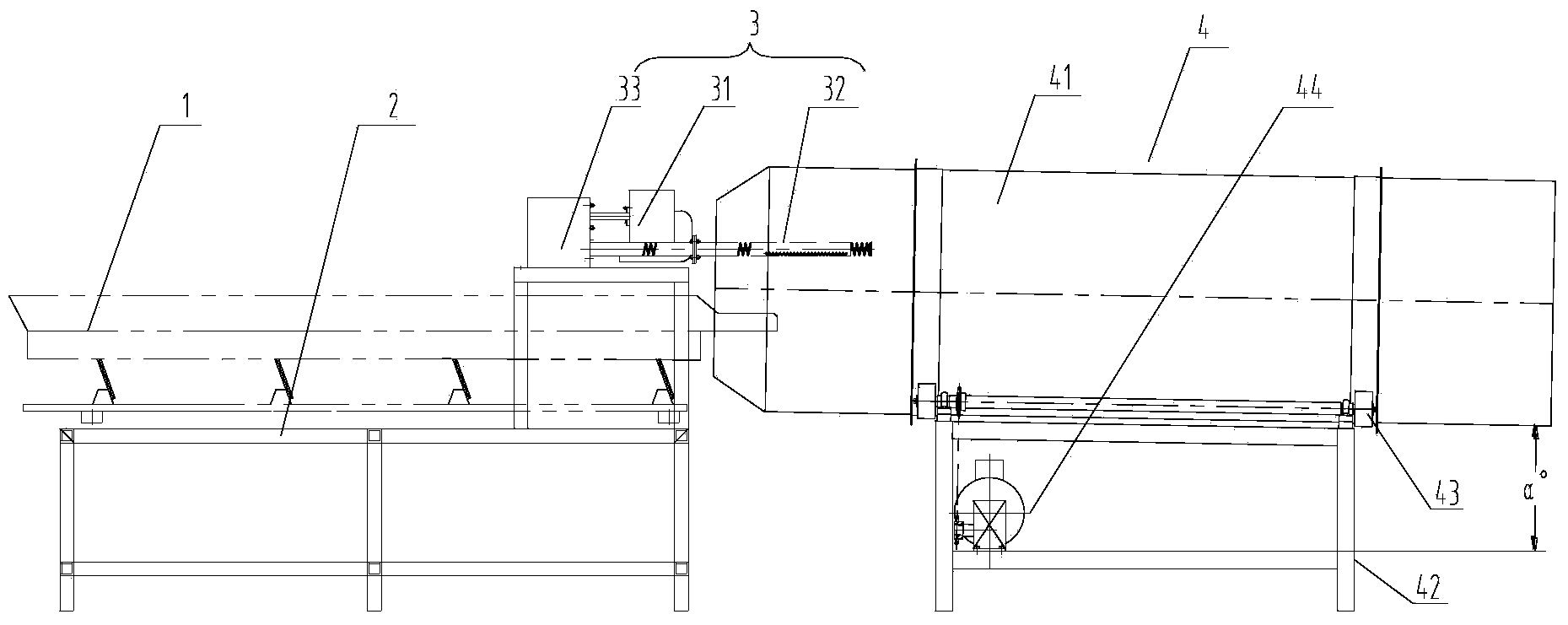

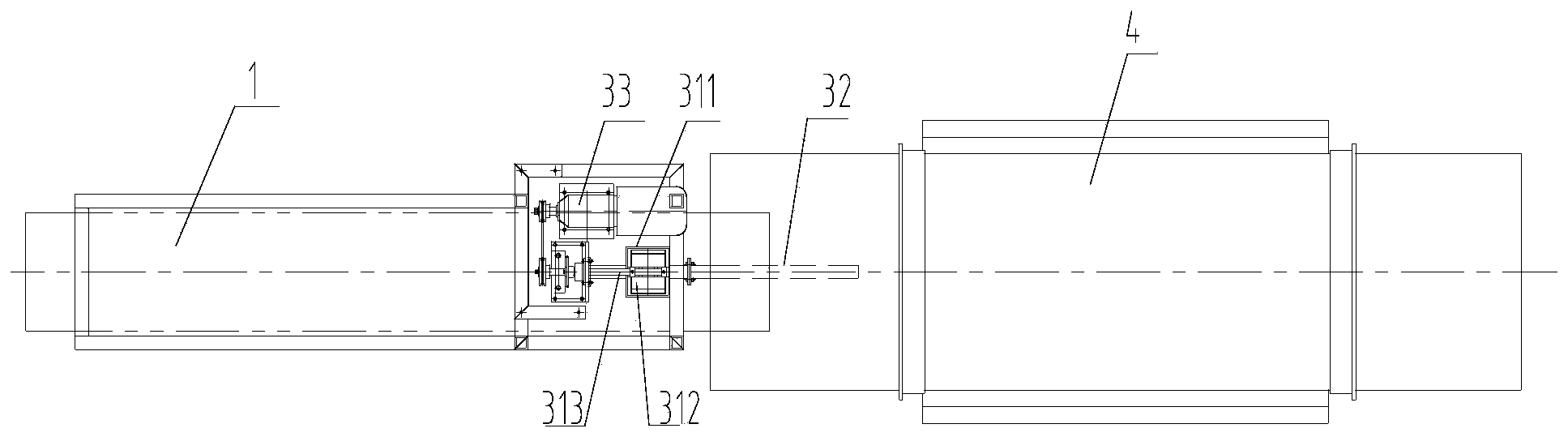

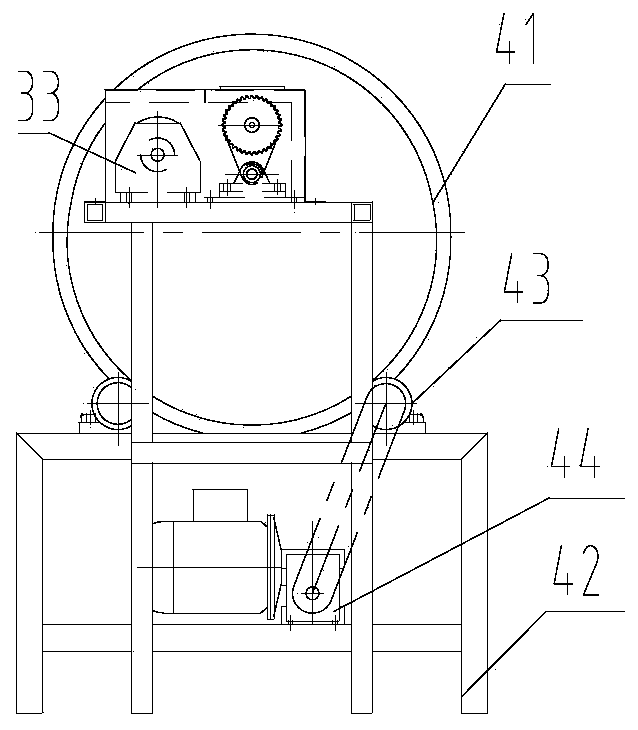

[0030] figure 1 , figure 2 with image 3 It is a potato chip seasoning machine provided by the present invention, which includes a feeding device 1 , a powder mixing device 3 and a homogenizing device 4 . Wherein feeding device 1 is used for conveying French fries or potato chips material; Powder mixing device 3 comprises powder mixing device 31, feeding pipe 32 and first drive motor 33, and feeding pipe 32 is positioned at the below of powder mixing device 31 and mixes powder The mixer 31 is connected, and the various powders that have been stirred are put into the powder mixer, stirred and dropped into the feeding pipe 32, and are transported to the homogenizing device 4 through the feeding pipe 32. The first drive motor 33 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com