Bamboo batten mat production line

A bamboo mat and production line technology, which is applied to wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of distortion, high production cost and cracking of bamboo mats, so as to improve the utilization rate and reduce the waste rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing example the present invention is described in further detail:

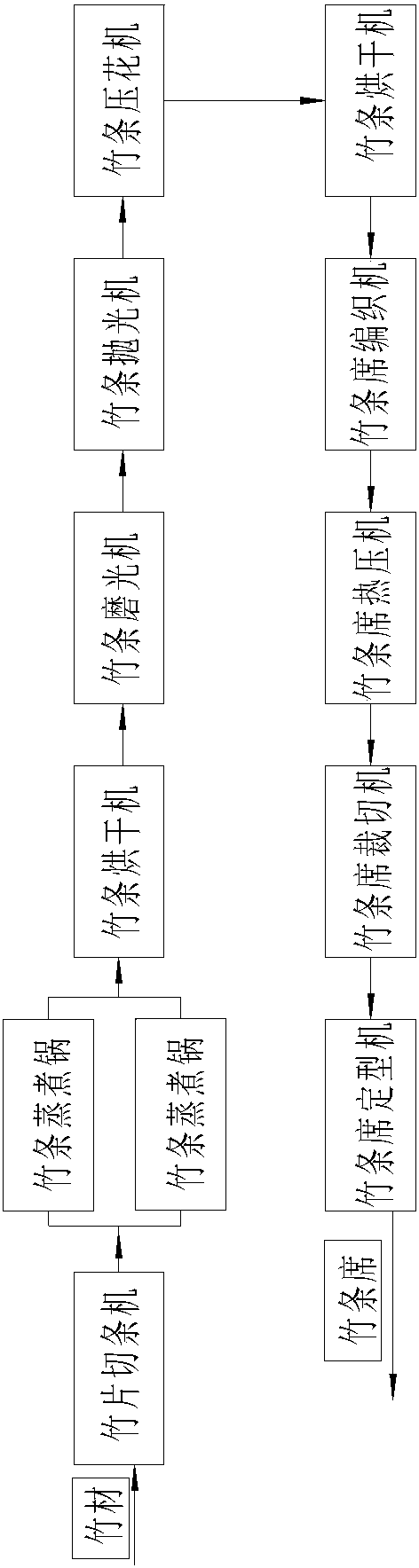

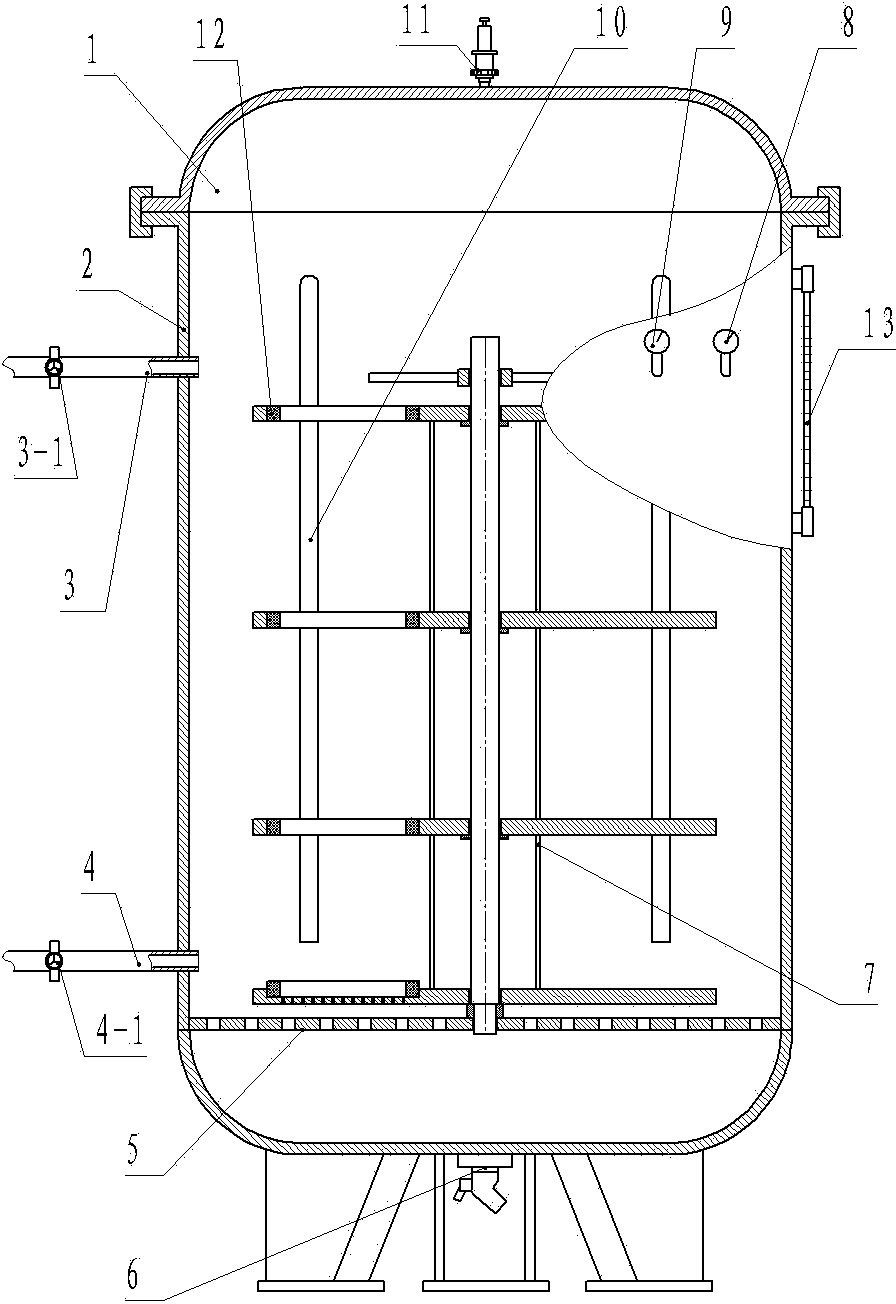

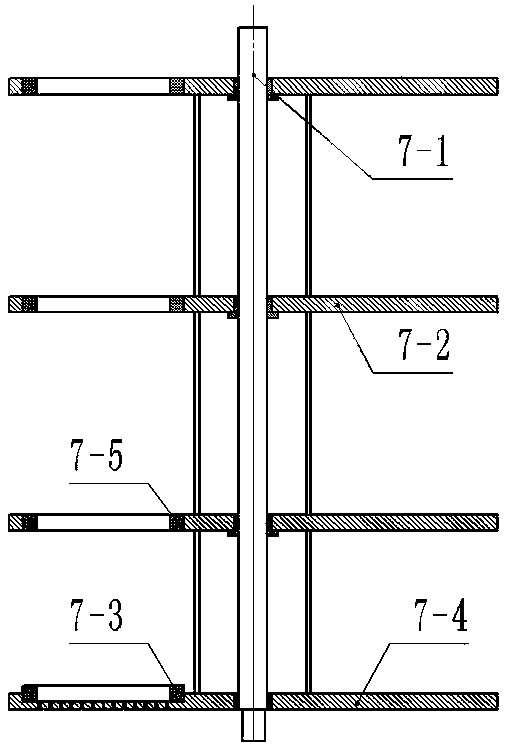

[0014] like figure 1 The bamboo mat production line shown includes a bamboo strip cutting machine, a bamboo strip polishing machine connected by a conveyor belt, a bamboo strip polishing machine, a bamboo strip embossing machine, a bamboo strip drying machine, a bamboo strip mat weaving machine, a bamboo strip mat Strip mat hot press machine, bamboo strip mat cutting machine and bamboo strip mat shaping machine, present embodiment is equipped with two bamboo strip cooking pots and a bamboo strip oven between bamboo strip cutting machine and bamboo strip polishing machine Dryer; such as figure 2 , image 3 and Figure 4 The shown bamboo cooking pot includes a pot body 2 and a cover body 1 installed on the pot body 2, and a water inlet pipe 3 connected to a check valve 3-1 is installed on the pot body 2, and a check valve 4-1 is connected to the pot body 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com