Motor shaft quenching equipment

A technology for quenching equipment and motor shafts, applied in the direction of quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of low production efficiency, pollution, and large difference in quenching hardness, etc., to improve production efficiency, reduce labor intensity, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

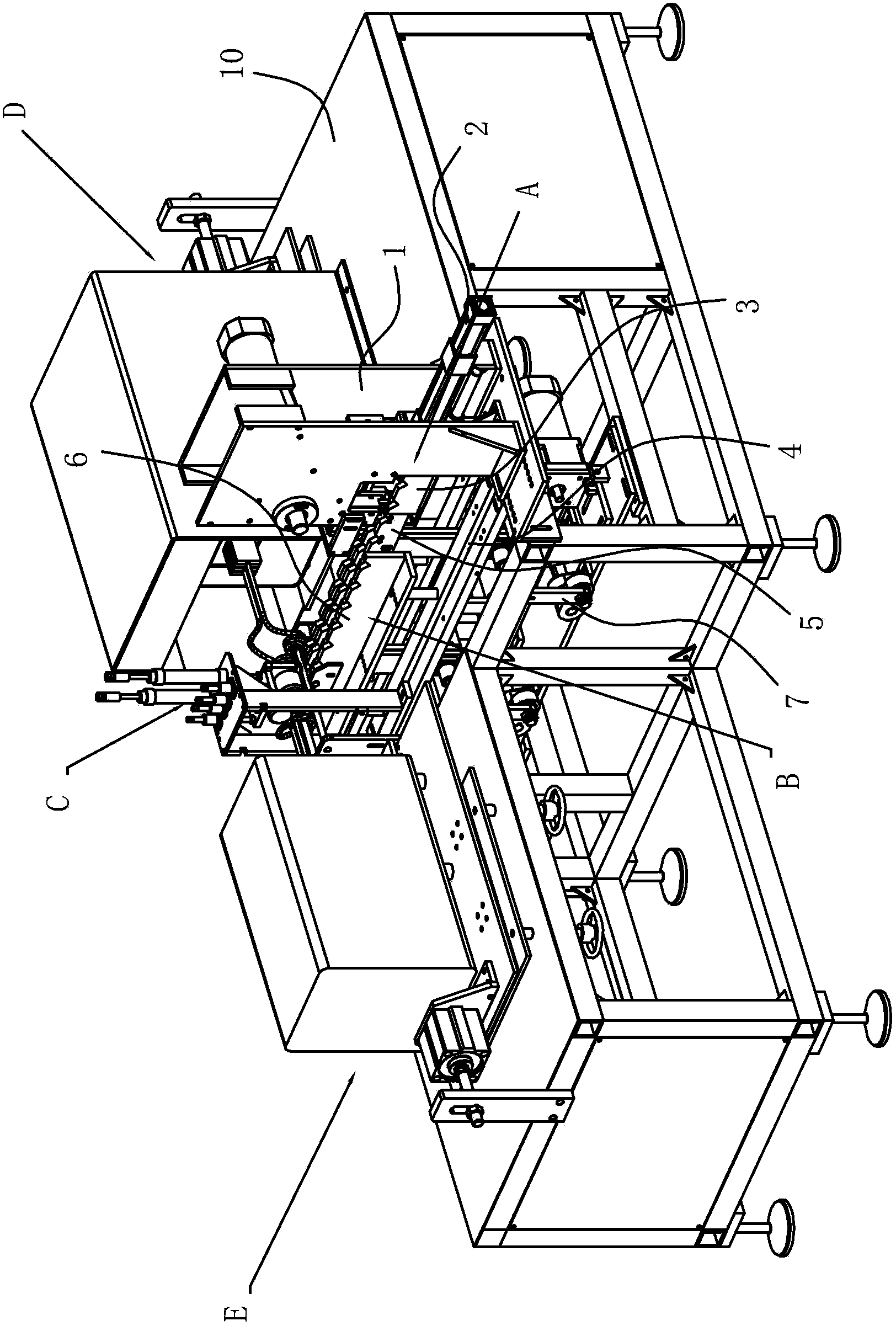

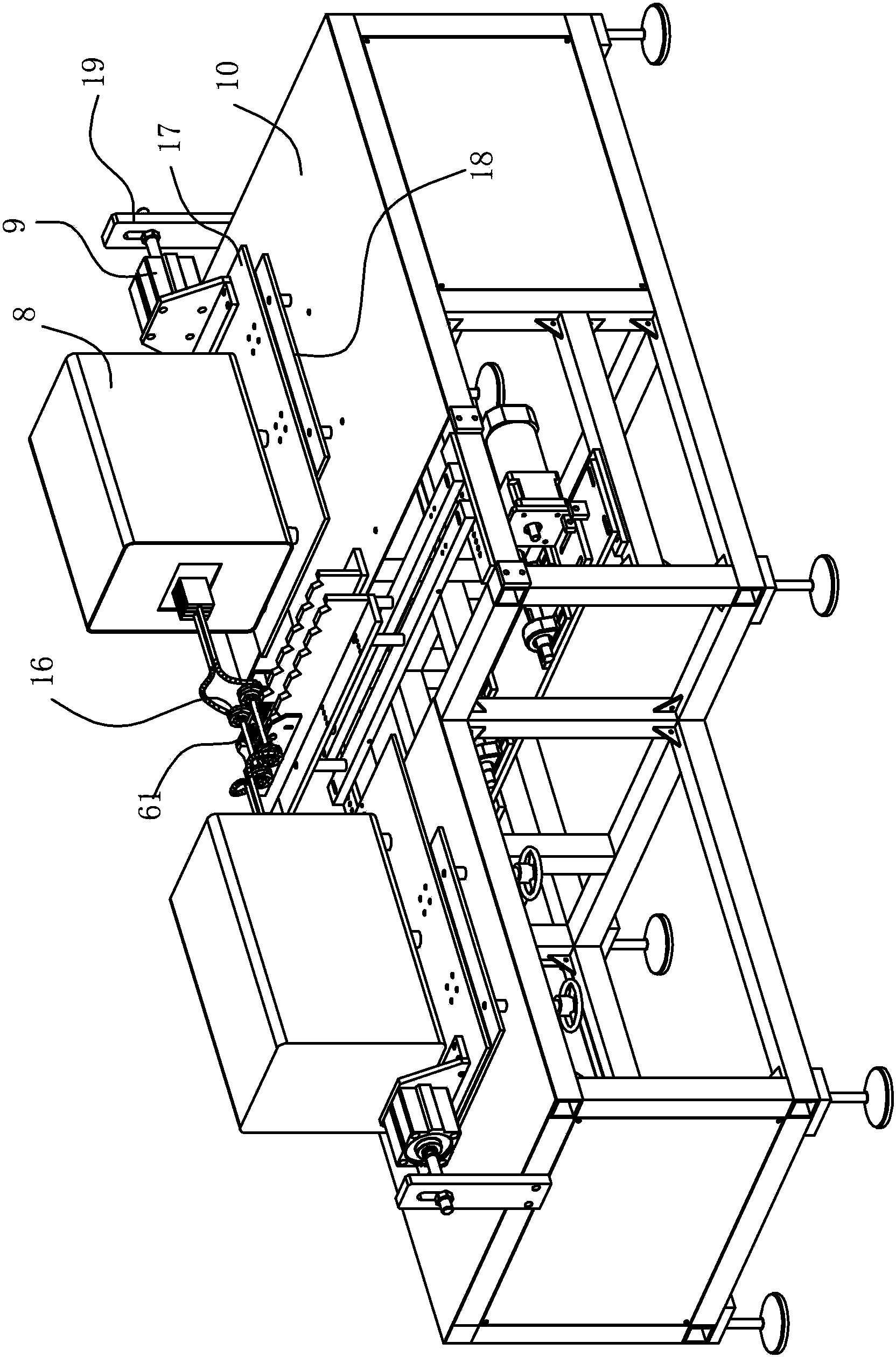

[0029] As shown in the figure, a fully automatic serial excitation motor shaft quenching equipment is mainly composed of automatic discharge and feeding mechanism A, automatic feeding and discharging mechanism B, pressing and rotating mechanism C, quenching sending and retracting mechanism, cooling mechanism and program control Composed of the system, the automatic discharge feeding mechanism A and the automatic feeding and discharging mechanism B are sequentially set on a strip-shaped machine base 4 from the back to the front;

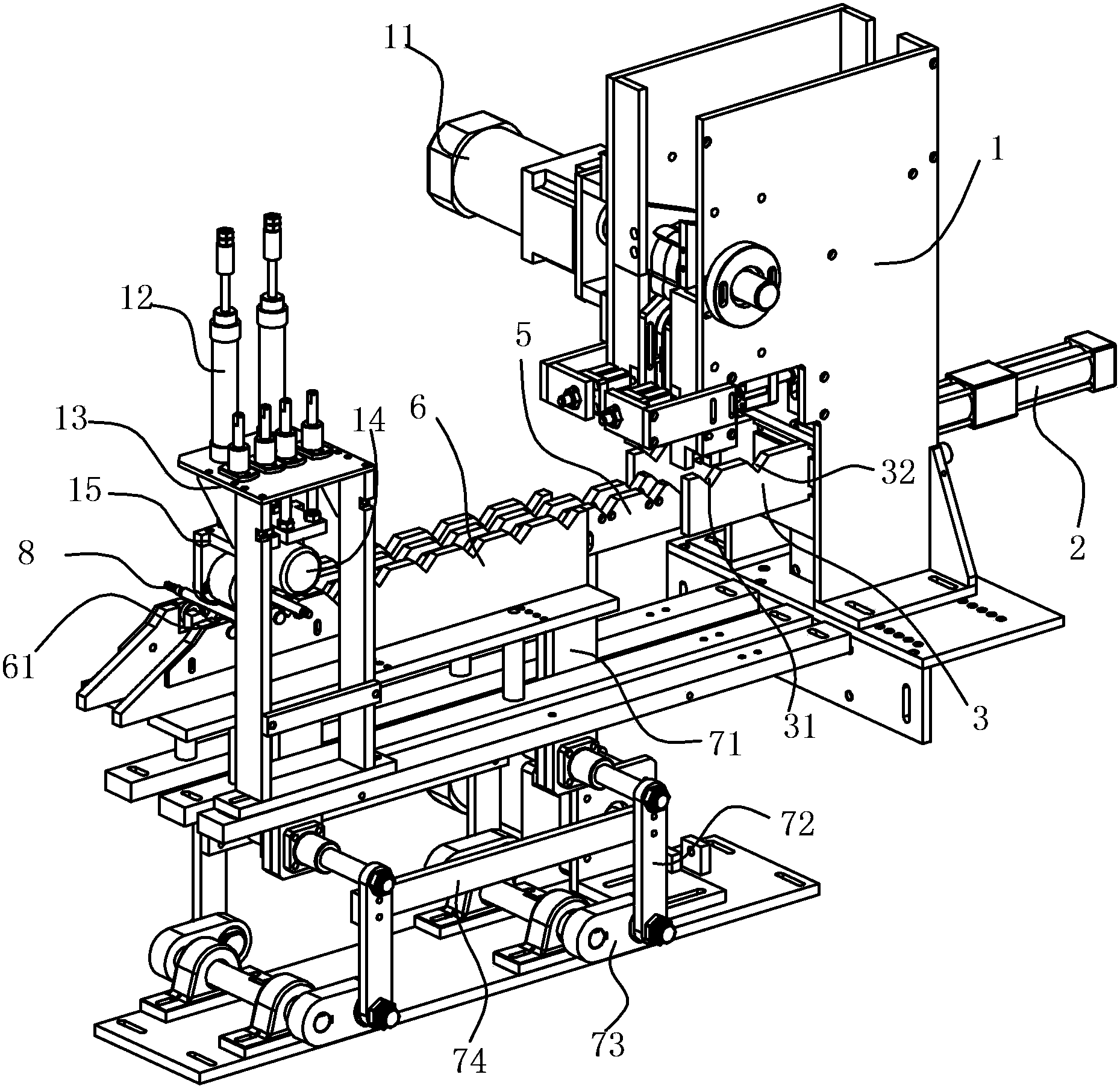

[0030] The automatic discharge and feeding mechanism A includes a hopper 1, a linear feeding plate 3, a feeding motor 11 for driving the feeding opening, and a feeding cylinder 2. The hopper 1 is erected at the rear of the machine base 4, and the feeding motor 11 is installed on the side of the hopper 1. There are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com