Low-temperature deep-cycle positive grid alloy and preparation method thereof

A deep cycle and positive plate technology is applied in the field of low temperature deep cycle lead-acid battery positive grid alloy and its preparation, which can solve the problems of limiting the deep cycle performance of the battery and the large resistance of the anode corrosion film, so as to improve the deep cycle performance, The effect of good electrical conductivity and uniform alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

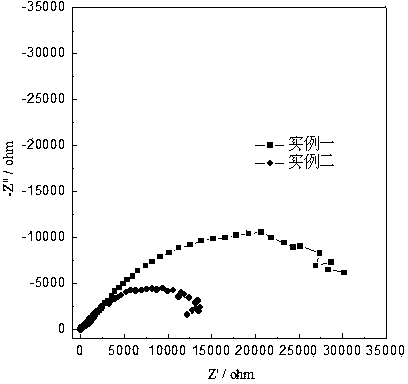

Examples

Embodiment 1

[0028] A method for preparing a low-temperature deep-cycle positive electrode grid alloy, characterized in that it comprises the following steps:

[0029] (1) Raw material preparation: lead, calcium, tin and aluminum, and the mass percentage of each raw material in the total raw material is: calcium: 0.09%, tin: 1.8%, aluminum: 0.05%, zinc: 0.01%, and lead is the balance;

[0030] (2) Add lead grains accounting for 85% of the total mass of lead raw materials into the graphite lead melting pot of the intermediate frequency furnace and heat to 670~680°C to fully melt the lead grains, and wrap and mix them with lead skin accounting for 0.5% of the total mass of lead raw materials Uniform calcium chips and broken aluminum flakes, and press them into the molten lead liquid together, and then stir for 2~3 minutes to mix the calcium and aluminum elements in the lead liquid evenly. During this process, keep the temperature of the melt at 670~ Between 680°C;

[0031] (3) Stop stirring...

Embodiment 2

[0035] A method for preparing a low-temperature deep-cycle positive electrode grid alloy, characterized in that it comprises the following steps:

[0036] (1) Raw material preparation: lead, calcium, tin and aluminum, and the mass percentage of each raw material in the total raw material is: calcium: 0.09%, tin: 1.8%, aluminum: 0.05%, zinc: 0.08%, lead as the balance;

[0037] (2) Add lead grains accounting for 85% of the total mass of lead raw materials into the graphite lead melting pot of the intermediate frequency furnace and heat to 670~680°C to fully melt the lead grains, and wrap and mix them with lead skin accounting for 0.5% of the total mass of lead raw materials Uniform calcium chips and broken aluminum flakes, and press them into the molten lead liquid together, and then stir for 2~3 minutes to mix the calcium and aluminum elements in the lead liquid evenly. During this process, keep the temperature of the melt at 670~ Between 680°C;

[0038] (3) Stop stirring and...

Embodiment 3

[0042] A method for preparing a low-temperature deep-cycle positive electrode grid alloy, characterized in that it comprises the following steps:

[0043] (1) Raw material preparation: lead, calcium, tin and aluminum, and the mass percentage of each raw material in the total raw material is: calcium: 0.09%, tin: 0.5%, aluminum: 0.05%, zinc: 0.2%, and lead as the balance;

[0044] (2) Add lead grains accounting for 85% of the total mass of lead raw materials into the graphite lead melting pot of the intermediate frequency furnace and heat to 670~680°C to fully melt the lead grains, and wrap and mix them with lead skin accounting for 0.5% of the total mass of lead raw materials Uniform calcium chips and broken aluminum flakes, and press them into the molten lead liquid together, and then stir for 2~3 minutes to mix the calcium and aluminum elements in the lead liquid evenly. During this process, keep the temperature of the melt at 670~ Between 680°C;

[0045] (3) Stop stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com