Construction method and structure of dam toe hydropower station workshop retaining wall

A technology of hydropower plant and construction method, which is applied to hydropower stations, hydropower, water conservancy projects, etc., to achieve the effects of shortening water diversion lines, saving engineering investment, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

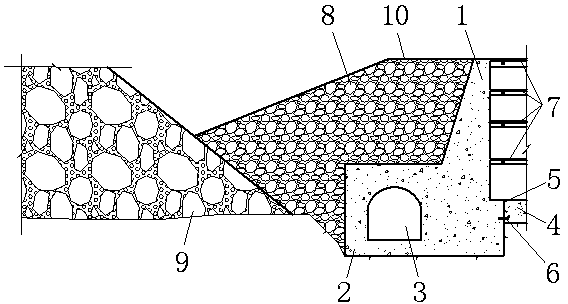

[0022] The construction method of the retaining wall of the powerhouse of the Bajiao Hydropower Station, such as figure 1 As shown, in this method, after the excavation of the foundation pit of the factory building is completed, the retaining wall of the factory building is firstly constructed on the side of the foundation pit close to the earth-rock dam, and a barrier is formed between the factory building and the earth-rock dam to prevent large rocks from the earth-rock dam construction. Rolling into the foundation pit of the factory building will endanger the safety of the factory building structure and construction personnel; the factory building retaining wall will be constructed according to the following steps:

[0023] A. Carry out the concrete construction of the counterweight platform; set u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com