Clutch booster high in sealing performance

A technology for clutches and boosters, which is applied to clutches, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of uncompensated sealing gaps, failure of clutch boosters, and reduced sealing effects, so as to achieve uniform force and good performance. Sealing effect, the effect of ensuring the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

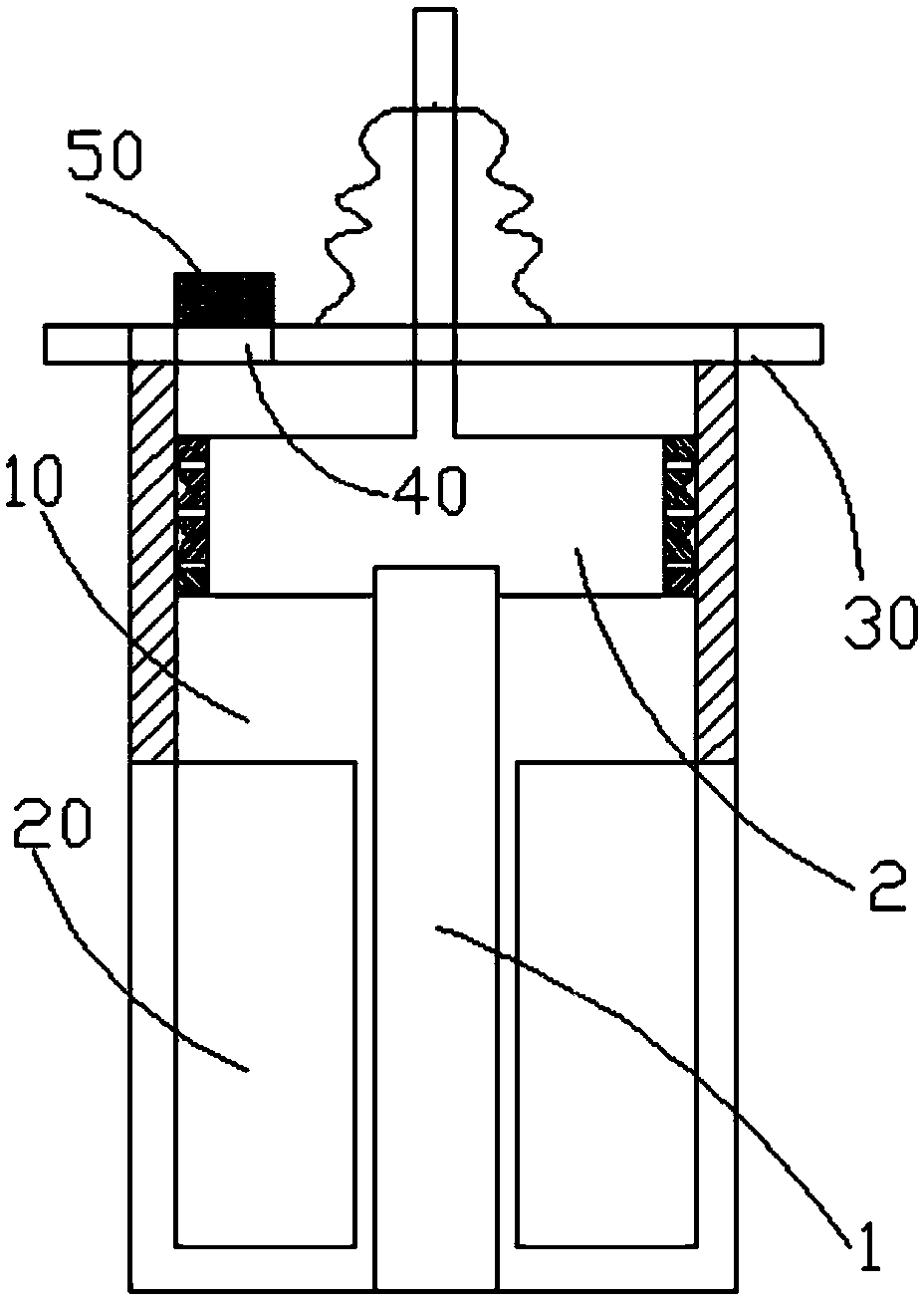

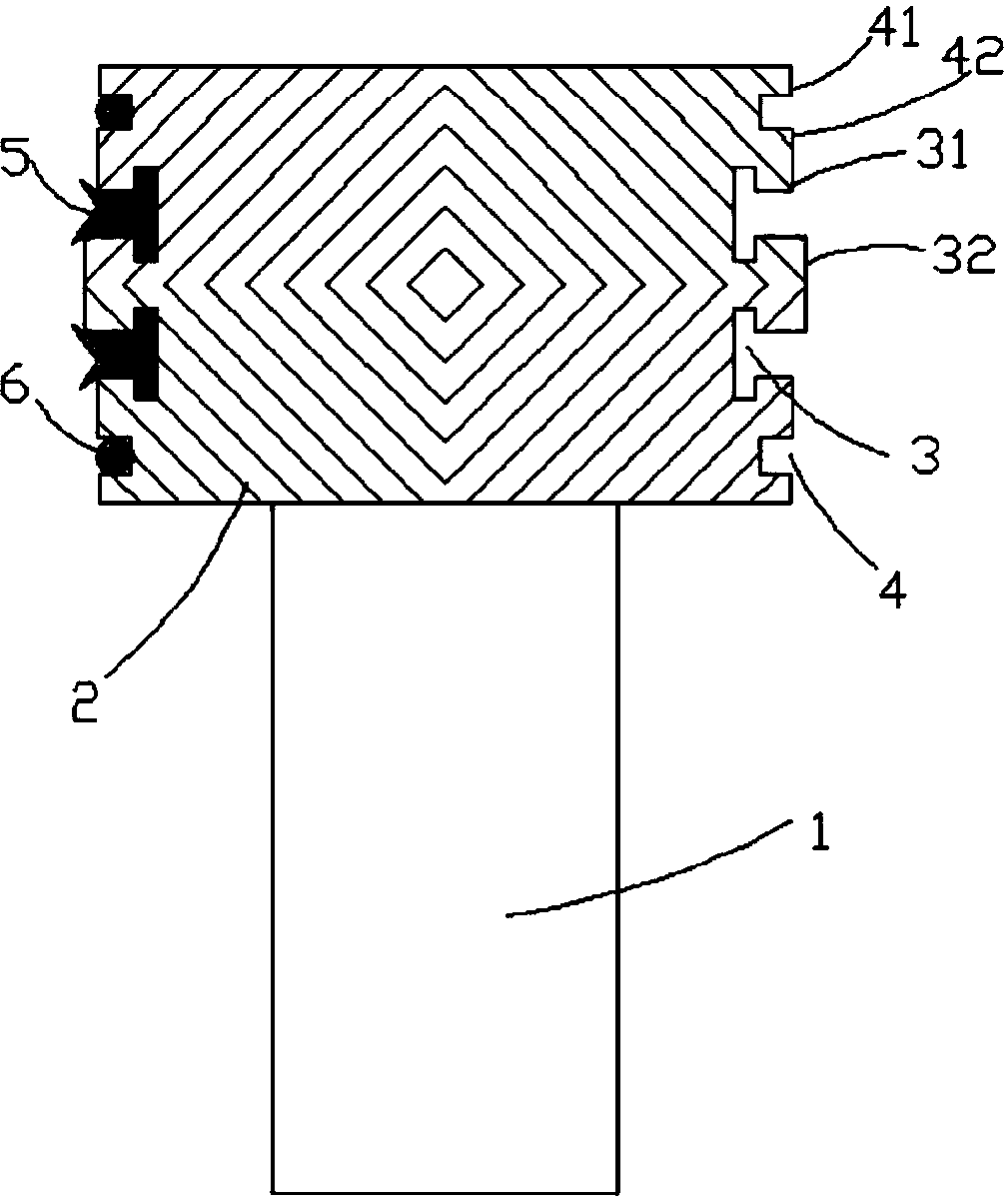

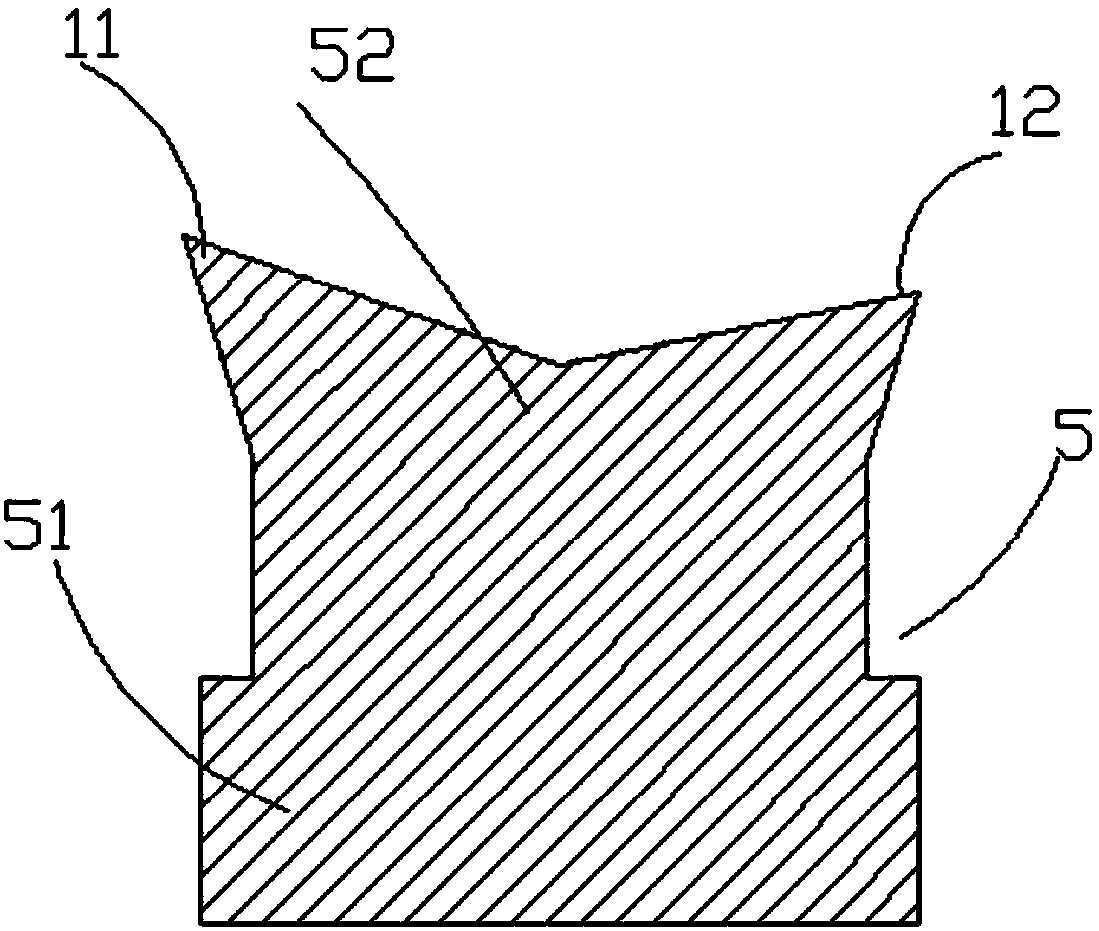

[0023] Such as figure 1 , figure 2 and image 3 As shown, the present invention relates to a clutch booster with good sealing, having a pneumatic cylinder 10 and a hydraulic cylinder 20 connected along the same axis, the piston is placed in the pneumatic cylinder 10, characterized in that the piston comprises a piston rod 1. A piston head 2 is formed at the end of the piston rod 1, two annular grooves 3 with a T-shaped cross section are formed on the outer wall of the piston head 2, and an annular clamping groove 4 is formed at the outer end of the annular groove 3; A sealing member 5 is provided inside, and a sealing ring 6 is provided in the annular slot 4; wherein, one end 31 of the annular slot 3 close to the annular slot 4 is lower than the other end 32, and the outer end 41 of the annular slot 4 is lower than the other end 32. at the inner end 42 .

[0024] Such as image 3 As shown, the sealing member 5 in the present invention includes a fixed end 51, and a Y-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com