Fluid control valve

A fluid control valve, ball technology, applied in the direction of diaphragm valve, balance valve, valve device, etc., can solve the problems such as the increase of the offset of the actuator and the decrease of the stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

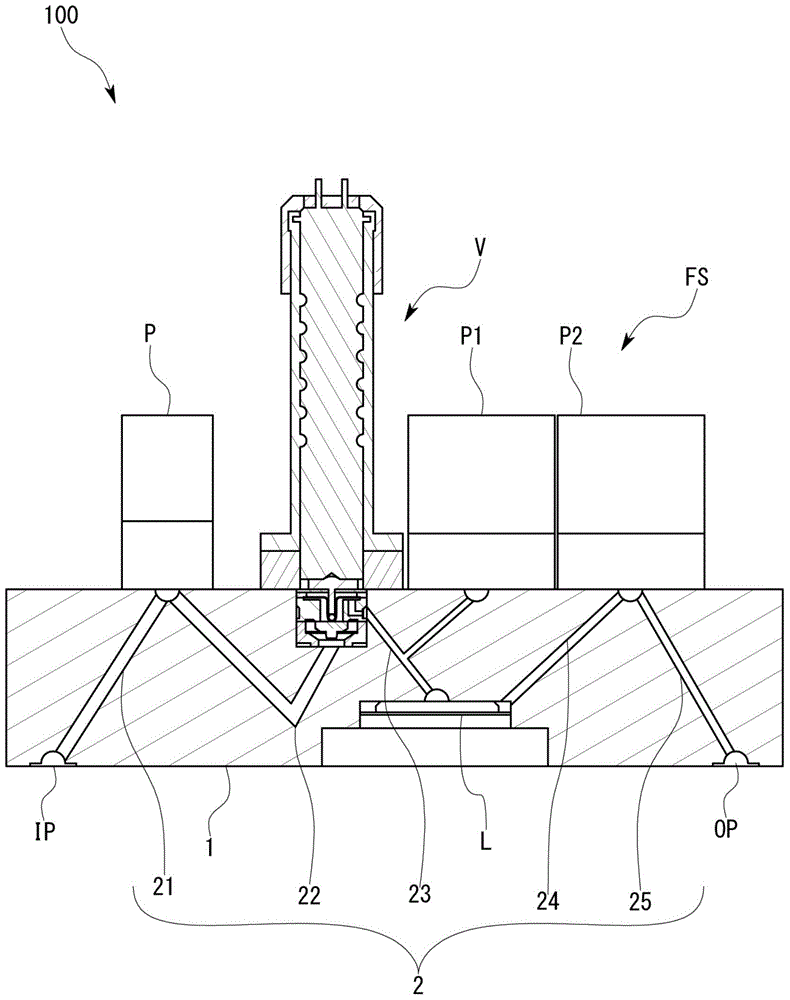

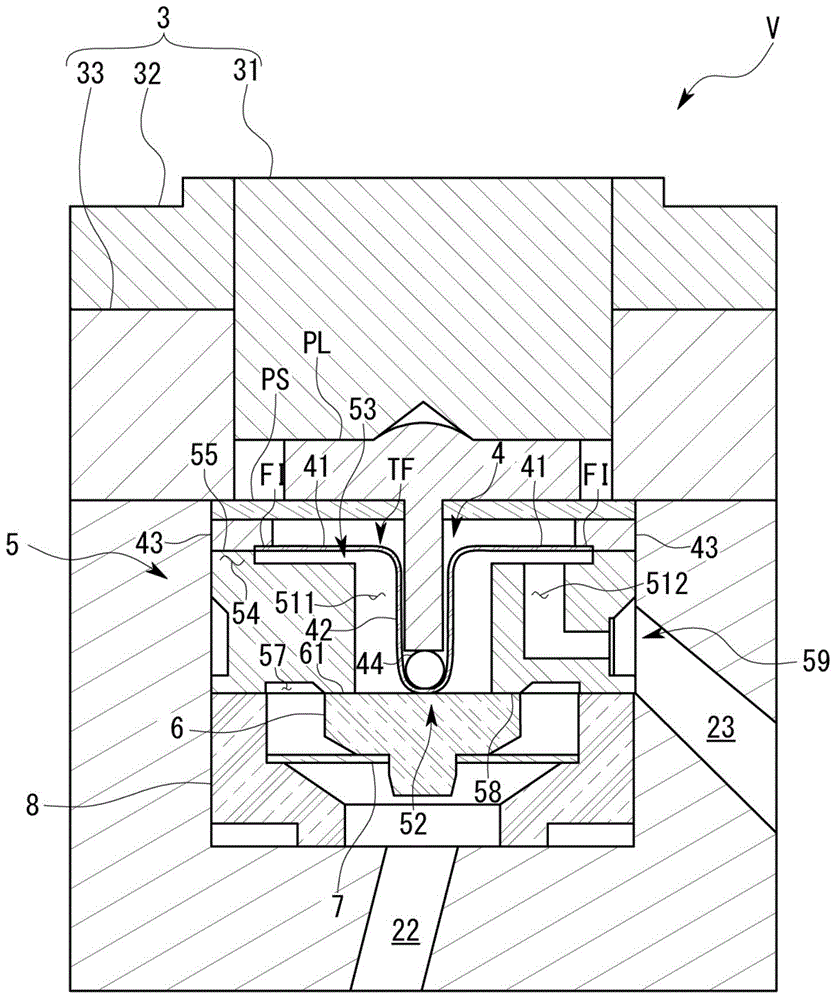

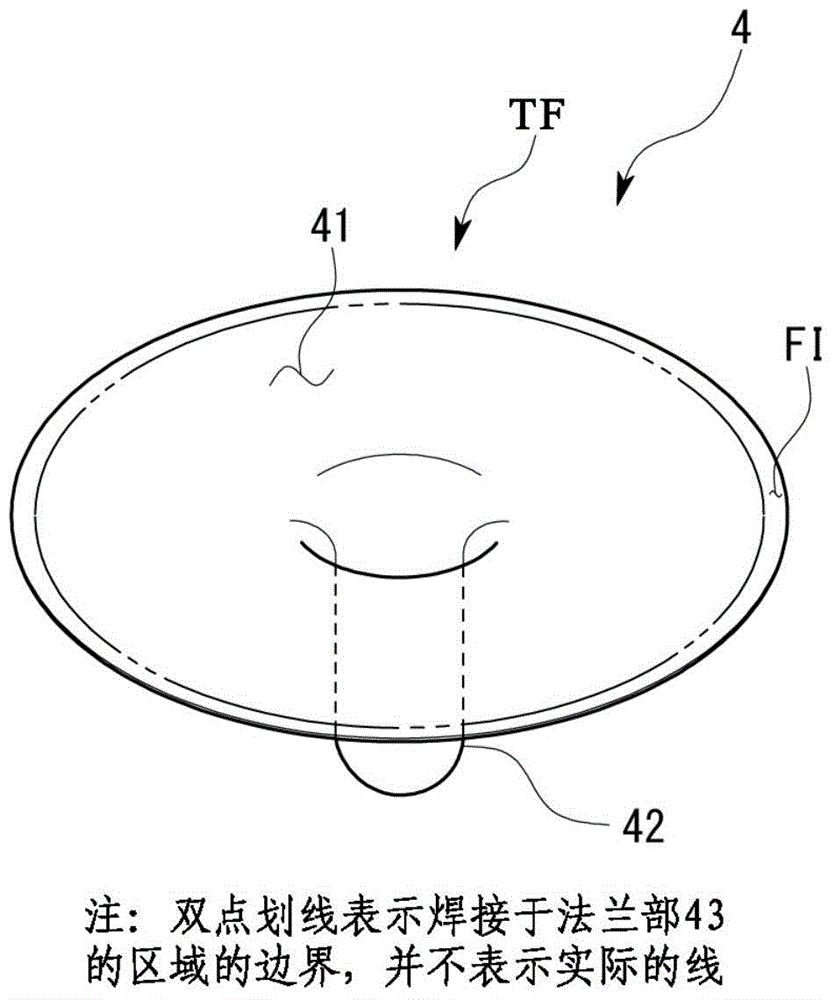

[0047] refer to Figures 1 to 6 The fluid control valve V and the mass flow controller 100 according to the first embodiment of the present invention will be described.

[0048] The mass flow controller 100 of the first embodiment is used in semiconductor manufacturing equipment such as figure 1 As shown, it includes: a main body 1, in which a flow channel 2 is formed to allow the fluid to be measured to flow; a primary pressure sensor P is used to measure the moment when the fluid flowing through the flow channel 2 flows into the main body 1 or enters the main body 1 before the pressure on the upstream side; the fluid control valve V is used to control the flow of the fluid flowing through the flow channel 2; the flow sensor FS is used to measure the flow of the fluid flowing through the flow channel 2; and the control part (not shown shown), feedback control the opening of the fluid control valve V to reduce the deviation between the target flow value and the measured flow ...

no. 2 approach

[0075] Then refer to Figure 8 and Figure 9 A second embodiment will be described. In addition, the same code|symbol is attached|subjected to the member corresponding to 1st Embodiment.

[0076] The fluid control valve V of the second embodiment differs from the first embodiment in the retaining structure of the ball 44 in the diaphragm structure 4 that transmits the force from the actuator 3 .

[0077] More specifically, as Figure 8 and Figure 9 As shown, the diaphragm structure 4 of the second embodiment also has an internal fitting member 45 that is tightly fitted to the inner peripheral surface of the protruding portion 42 and holds the protruding portion 42 . Sphere44.

[0078] The inner fitting member 45 has a substantially hollow cylindrical shape whose thickness increases from the upper side to the lower side, and the diameter of the outer peripheral surface is substantially the same as the inner diameter of the protruding portion 42 . A ball 44 that contacts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com