High-temperature steam heat pump unit

A heat pump unit, high temperature steam technology, applied in heat pump, steam generation, steam generation method and other directions, can solve the problems of low heating efficiency and poor heating effect, and achieve the effect of prolonging the service life, reducing the temperature of the refrigerant, and realizing the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

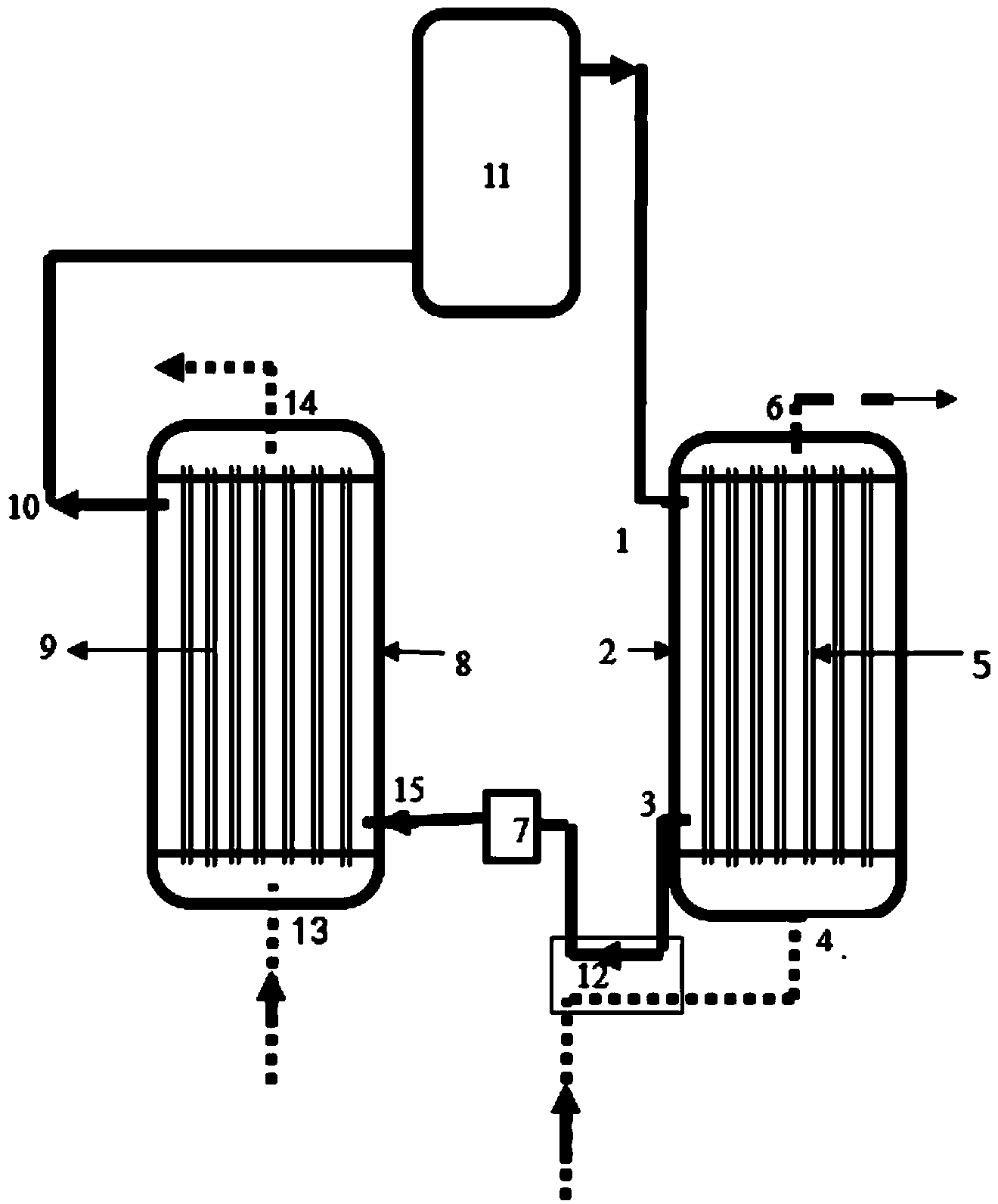

[0024] The high-temperature heat pump unit aimed at recovering waste hot water sources includes an evaporator, a compressor 11, a condenser, and an electronic expansion valve throttling device 7. The refrigerant evaporation outlet 10 of the evaporator is connected to the inlet of the compressor 11, and the outlet of the compressor 11 is connected to the inlet of the compressor 11. The refrigerant condensation inlet 1 of the condenser is communicated, and the refrigerant condensation outlet 3 of the condenser is communicated with the refrigerant evaporation inlet 15 of the evaporator through the electronic expansion valve throttling device 7 .

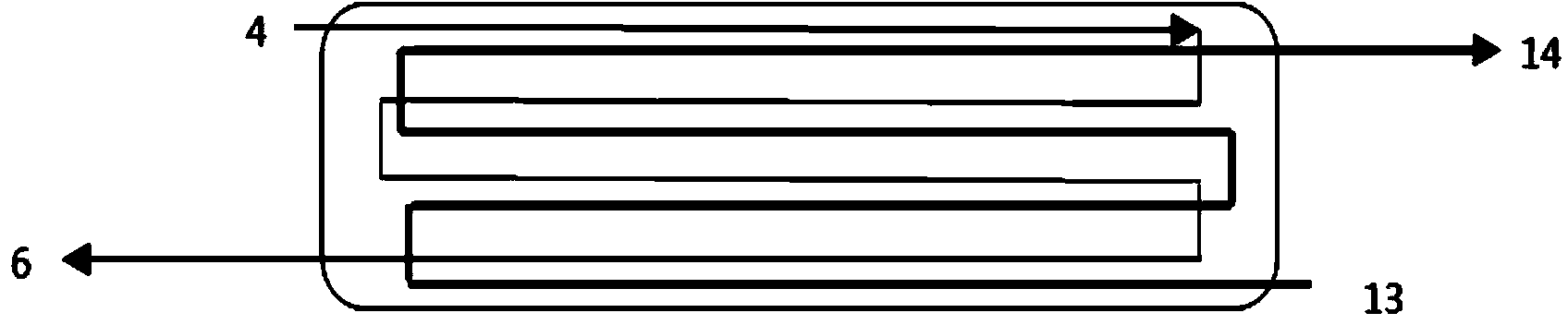

[0025] Such as figure 2 In the right half of the middle, the condenser includes a condensation chamber 2 and a condensed water heat exchange tube 5. There are three chambers in the condensation chamber 2 from top to bottom, which are the first chamber, the second chamber, the third chamber, and the second chamber A plurality of vertica...

Embodiment 2

[0034] For the high-temperature heat pump unit that recovers heat sources such as high-temperature exhaust gas and exhaust steam, a finned evaporator on the market is used, and it is sealed for heat exchange; the structure of the rest is the same as that of the first embodiment.

[0035] In addition, the evaporator adopts the existing horizontal arrangement structure and is used in combination with the condenser in this embodiment to generate waste water and steam, but the efficiency of evaporation and heat exchange is lower than that of Embodiment 1.

[0036] In Embodiment 1 and Embodiment 2, after the generated boiling water vapor is utilized, the remaining waste heat can be recovered and recycled as a part of the waste heat source, which can further improve the efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com