Apparatus and method for photographing glass defects in multiple layers

A technology on glass and glass, used in measuring devices, material analysis by optical means, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

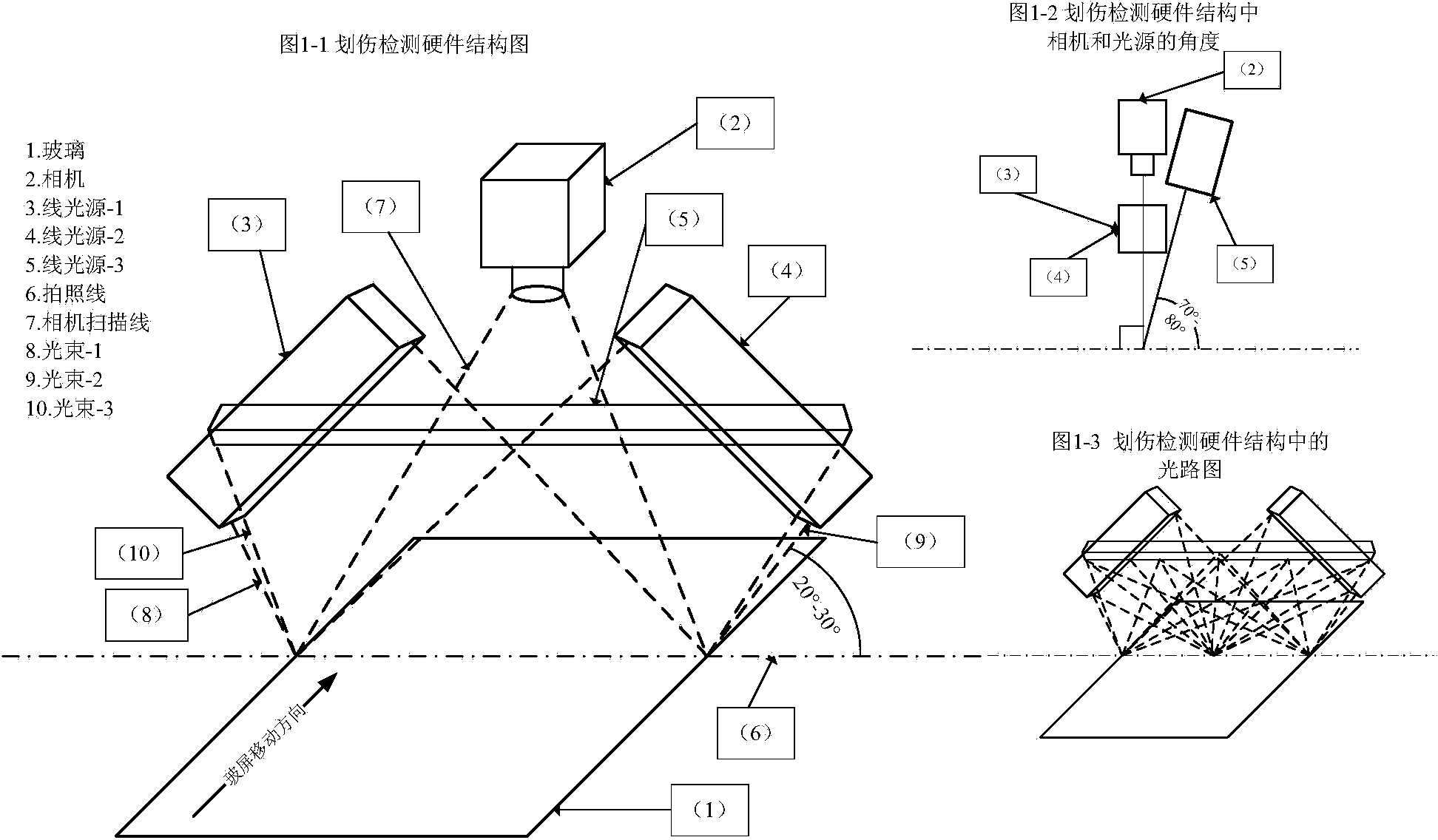

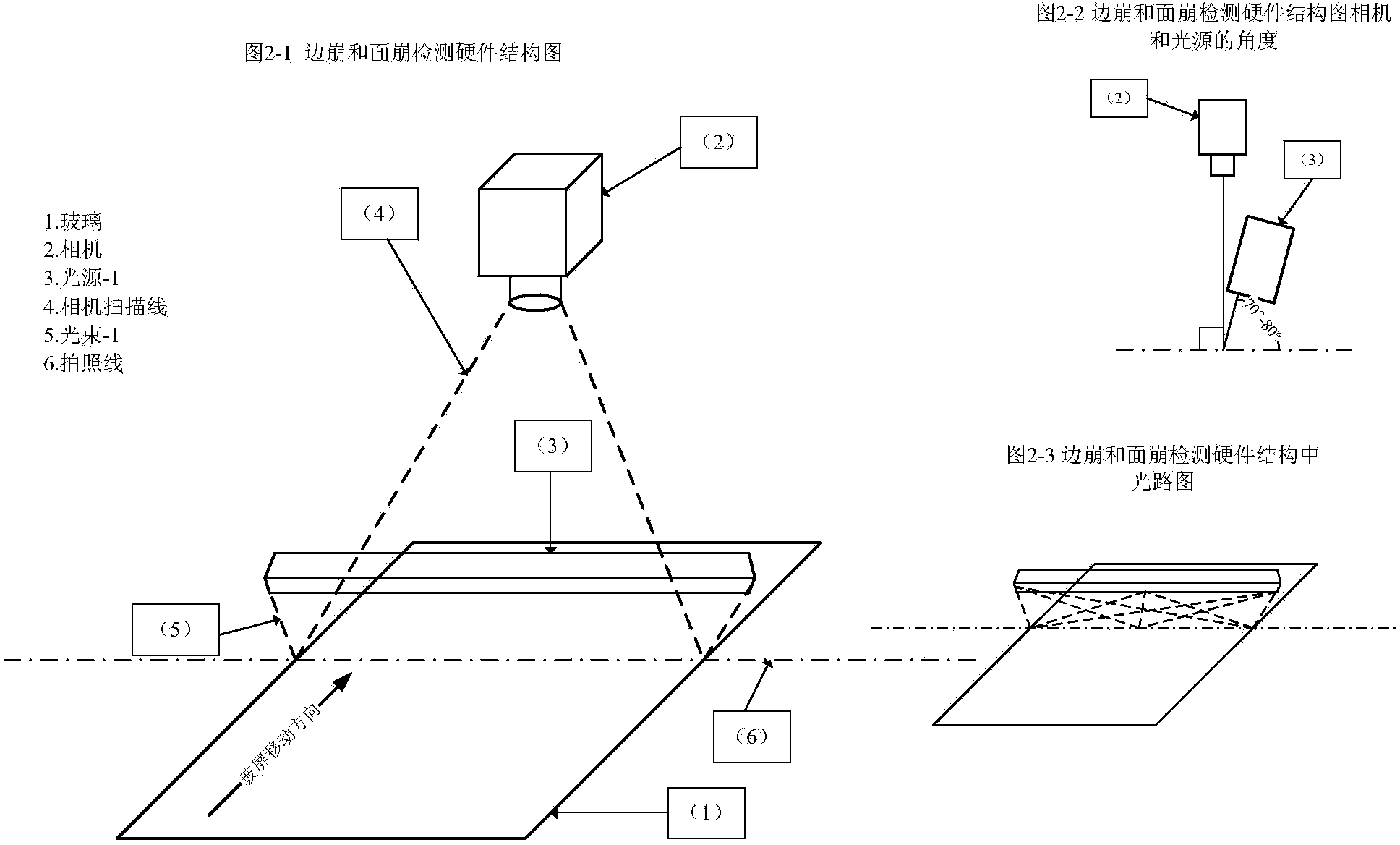

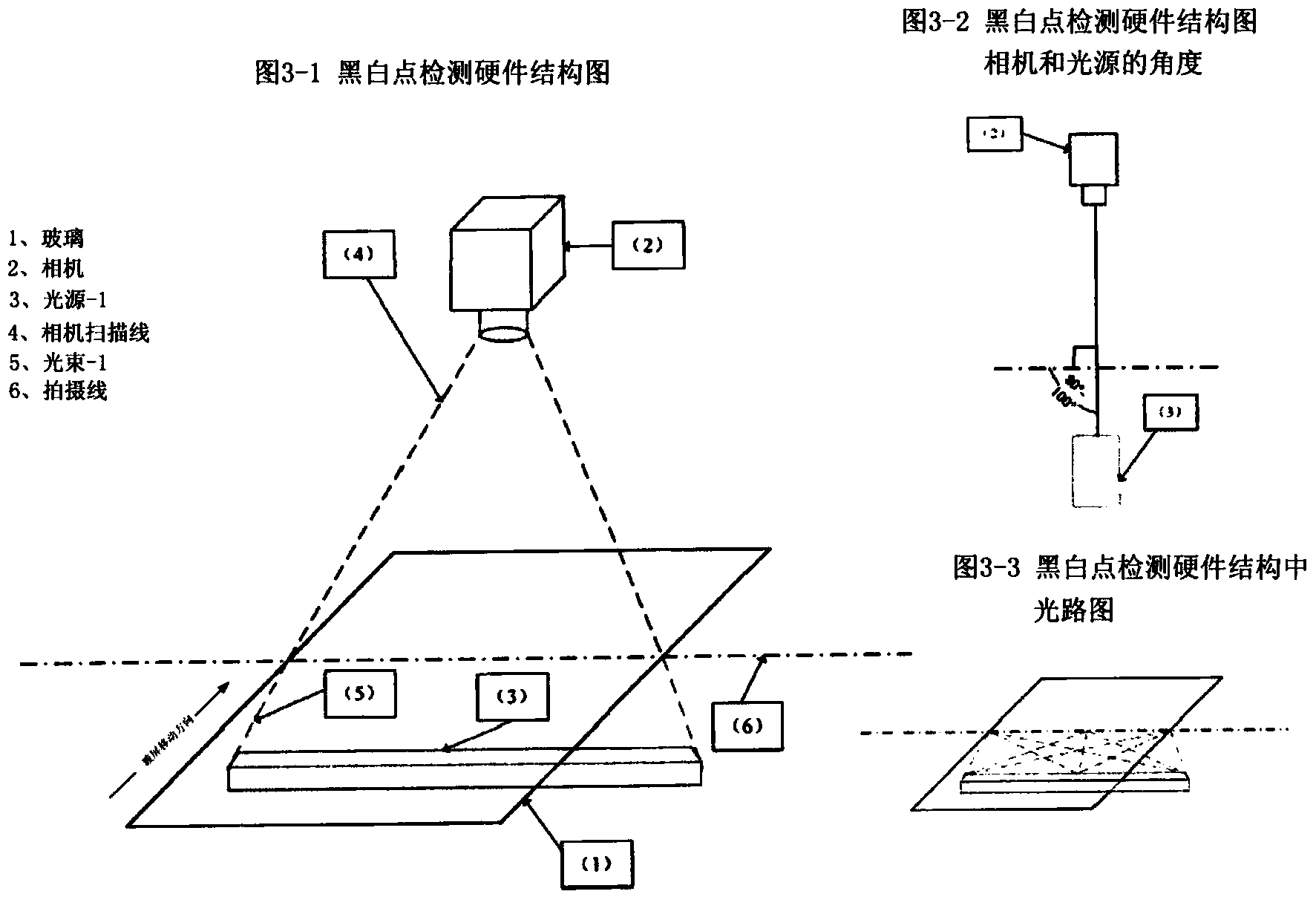

[0048] It must be stated that the types of glass screen defects that can be photographed by the imaging device described in the present invention include but are not limited to scratches, edge collapse / surface collapse, black and white spots, light leakage, cracks, pinholes, bumps, bubbles and Dirt, these defects may be distributed on the surface, back and middle layers of the glass screen. The mechanical structure of the device and photography involves a transmission device, one (or more) line frame (or surface frame) cameras, one (or more) strip light sources (or surface light sources), and one or more common Lens (low precision) or microlens (high precision); among them, the transmission device can be a roller conveyor, air-floating conveyor or any other type of conveyor, if you choose a wire frame camera then the conveyor must leave enough space For line scanning, the corresponding light source can be linear or square, the lens is an ordinary lens or a micro lens, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com