gas grill

A barbecue and gas-fired technology, which is applied to the field of gas-fired barbecues, can solve the problems of insufficient utilization of thermal efficiency, unfavorable large-scale promotion and utilization, pollution of the environment by oil fume, etc., and achieves better roasting effect, simple structure, and combustion. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

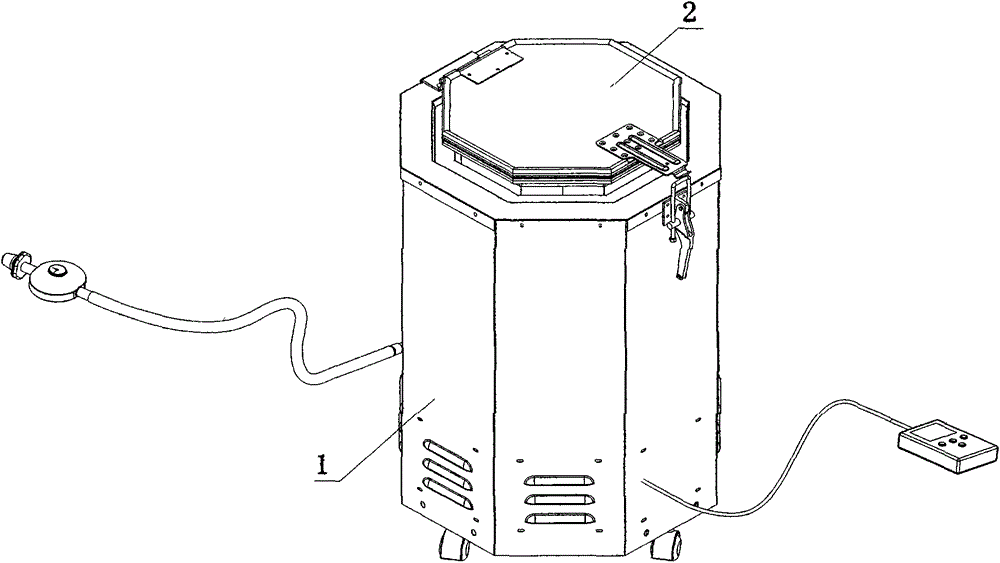

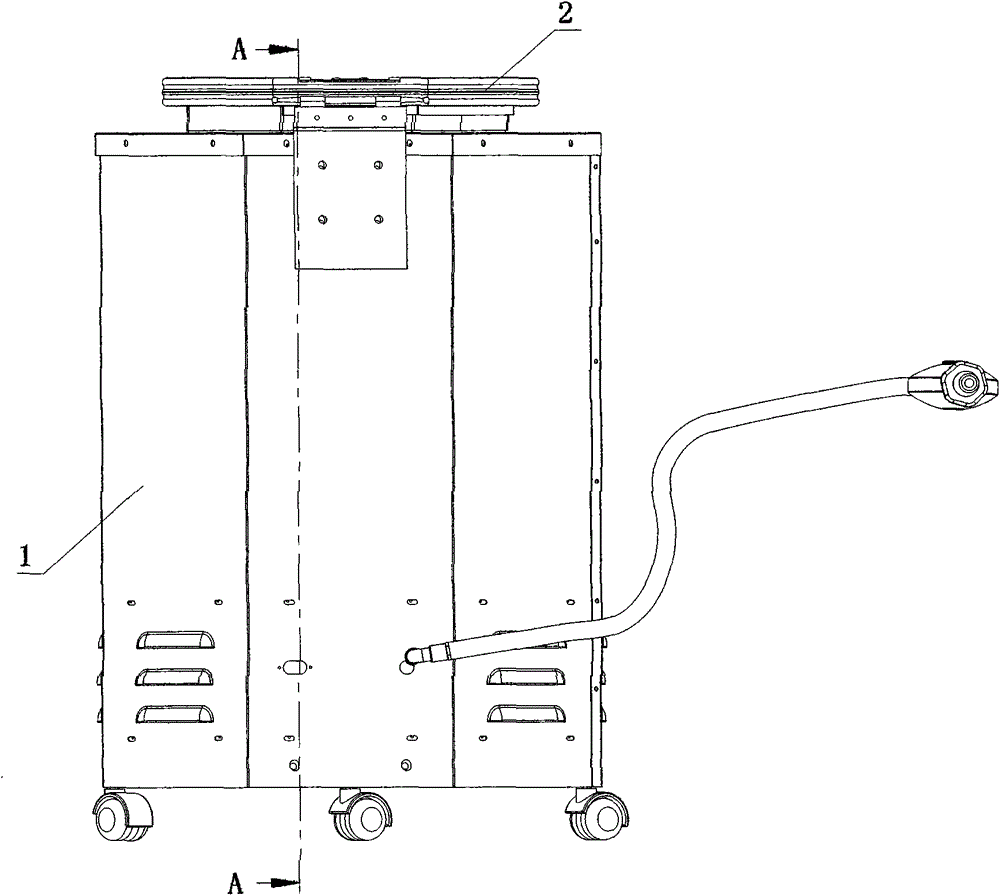

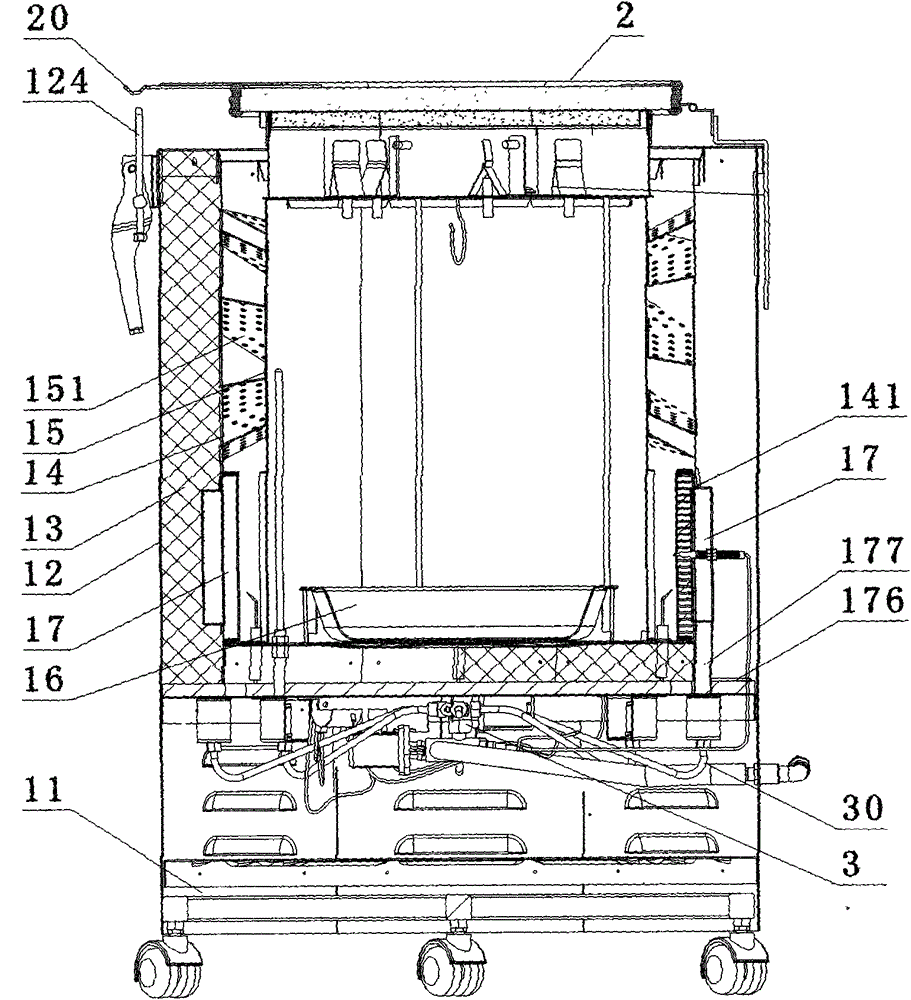

[0032] like figure 1 , figure 2 and image 3As shown, the gas-fired barbecue oven of this embodiment includes a furnace body 1 and a furnace cover 2 that are hingedly connected to each other. The thermal cotton cover 13, the inner tank 14 and the inner tank 15, the outer wall of the inner tank 15 is located on the upper side of the burner head 17 and is provided with a plurality of gas baffles 151 with through holes in a spiral rising arrangement, and the inner tank 15 The cavity is provided with a hanging pan 16 supported on the furnace body 1, a plurality of burner heads 17 are provided between the inner container 14 and the inner container 15, and a gas control assembly including a plurality of gas distribution pipes 30 is provided in the base assembly 11. 3. The gas distribution pipes 30 correspond to the burner heads 17 one by one, and the gas distribution pipes 30 are respectively connected to the corresponding burner heads 17 . In this embodiment, the food to be gri...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, the difference being that the gas control assembly 3 is different. like Figure 11 and Figure 12 As shown, the gas control assembly 3 in this embodiment includes an intake pipe 31, an intake valve 36, a gas distribution valve 37 and an electronic control unit 35. Trachea 30 links to each other with distributing valve 37 respectively, and the end of distributing pipe 30 links to each other with corresponding burner head 17 through gas nozzle 301, and gas distributing valve 37 is also provided with a plurality of normal valves corresponding to number and burner burner 17 one-to-one. The open flame gas pipe 371, the gas distribution valve 37 is provided with the first gas control electromagnetic valve 372 for controlling the on-off of the gas distribution pipe 30, the second gas control solenoid valve 373 for controlling the on-off of the open fire gas pipe 371, and the open flame gas pipe 371. The end is set in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com