Pneumatic sliding plate type vehicle blocking device

A pneumatic skateboard and car-stopping technology, which is applied in the directions of transportation and packaging, railway car body parts, and forced railway car stoppers, etc., can solve the problems of heavy installation workload, high labor intensity of staff, and failure of car stoppers to raise the foundation, etc. Achieve the effect of improving the deformation resistance strength and impact strength and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

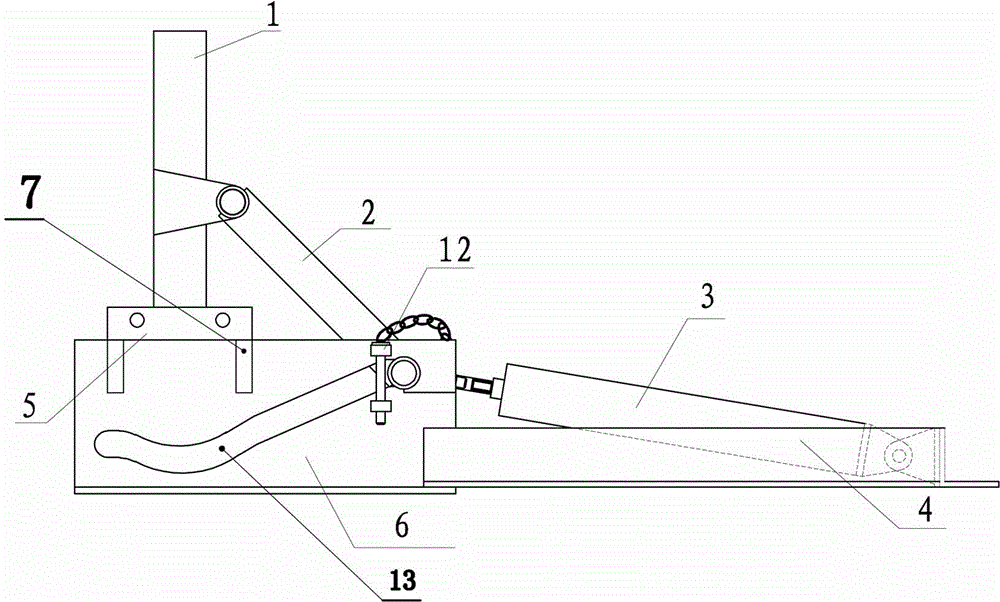

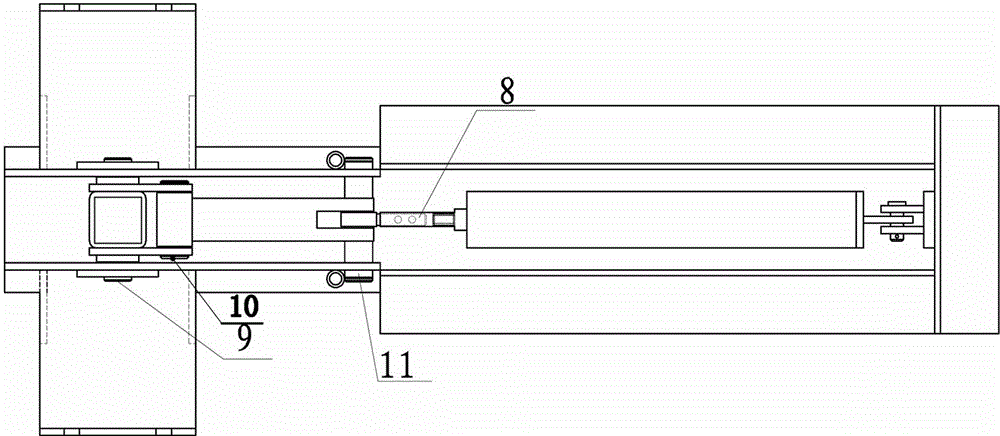

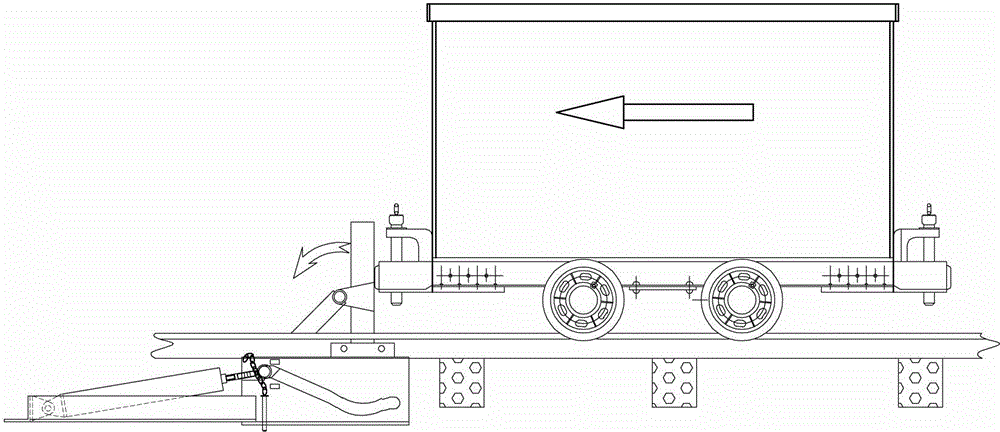

[0022] The present invention comprises cylinder 3, support bar 2, stop bar 1 and frame, and frame is made up of two parts of chute plate 6 and frame 4, and chute plate 6 is connected with frame 4 together, and frame 4 rear end side plate Cylinder 3 is hinged on the cylinder block, and cylinder 3 is contained in frame 4 inside, and two side plates of chute plate 6 are connected with stop bar 1 by car stop rotating shaft 9, and the supporting rotating shaft 10 on the car stop bar 1 is also hinged with Support rod 2, the other end of support rod 2 is also connected with sliding shaft 11, and sliding shaft 11 is contained in the inside of the chute 13 of two side plates of chute plate 6, and the head end of cylinder 3 piston rod is hinged on the slide through connecting rod 8. on axis 11. The chute 13 is a hollow groove with a circular arc transition milled out on the side plate, and the width of the chute 13 is greater than or equal to the outer diameter of the sliding shaft 11 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com