Magnetic rotation type spindle yarn feeding mechanism

A magnetic spinning, spindle technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve problems such as yarn breakage, and achieve the effect of preventing tearing and running evenly and smoothly up and down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention is further described:

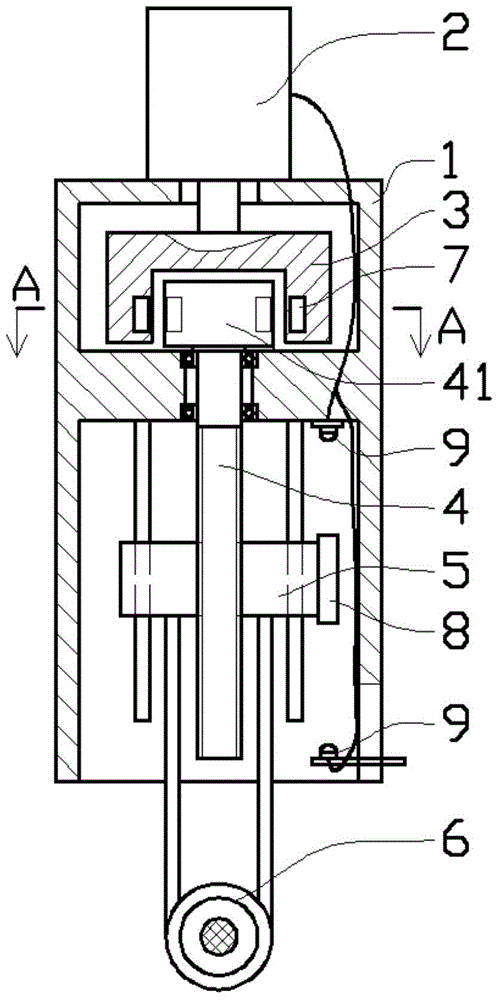

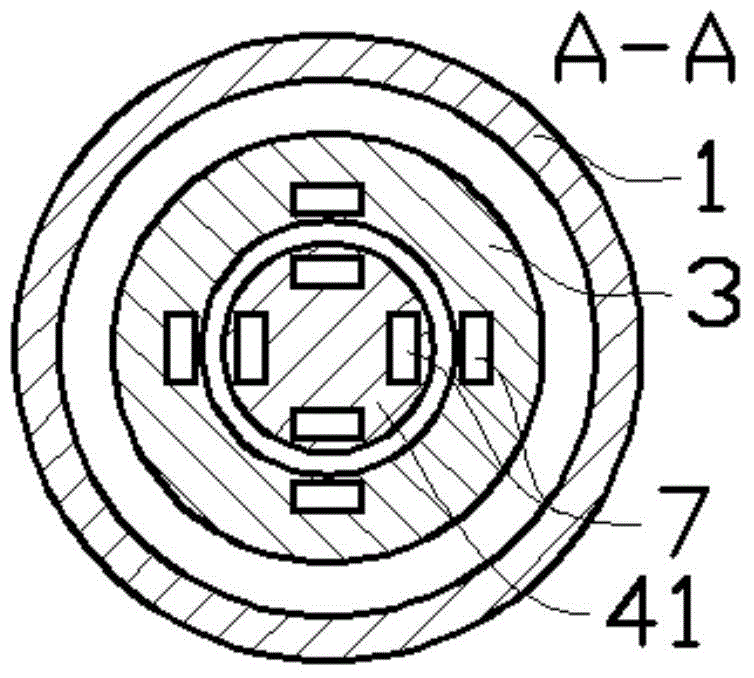

[0011] Such as figure 1 with figure 2 As shown in the embodiment, the magnetic rotary spindle thread feeding mechanism includes a housing 1, a micro motor 2, a transmission block 3, an adjustment screw 4, a sliding block 5, and a yarn guide ring 6; the housing 1 is cylindrical, The micro motor 2 is assembled on the upper part of the housing 1, the output shaft of the micro motor 2 is coaxial with the housing 1, the output shaft goes deep into the housing 1 and is connected with the transmission block 3, and the adjusting screw rod 4 The upper part of the rotating block 41 is fixed, and the lower part of the adjusting screw 4 is designed with a screw thread structure, and the adjusting screw 4 is coaxially assembled with the housing 1 . The rotating block 41 and the transmission block 3 are driven by the small magnetic block 7 corresponding to the position, and the sliding block 5 is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com