Bridge crane main beam

An overhead crane and main beam technology, which is applied in the directions of load hanging components, transportation and packaging, support structures, etc., can solve the problems of limited choice of main beams, consuming materials and power, increasing the weight of main beams, etc., to save energy and raw materials. , easy maintenance, and the effect of improving the carrying capacity of the crane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

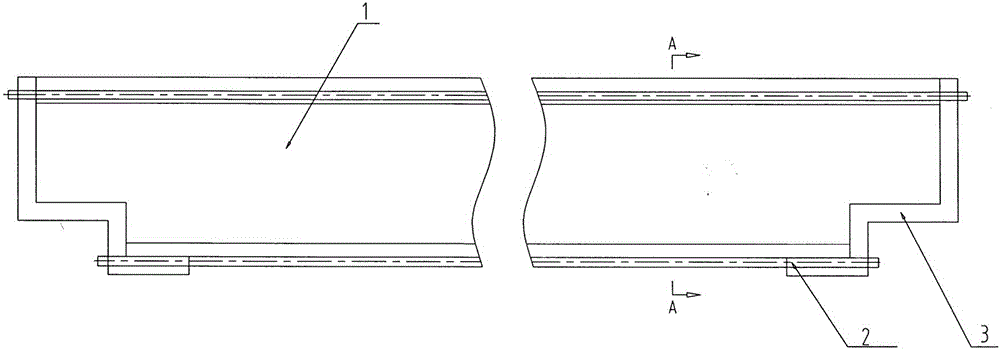

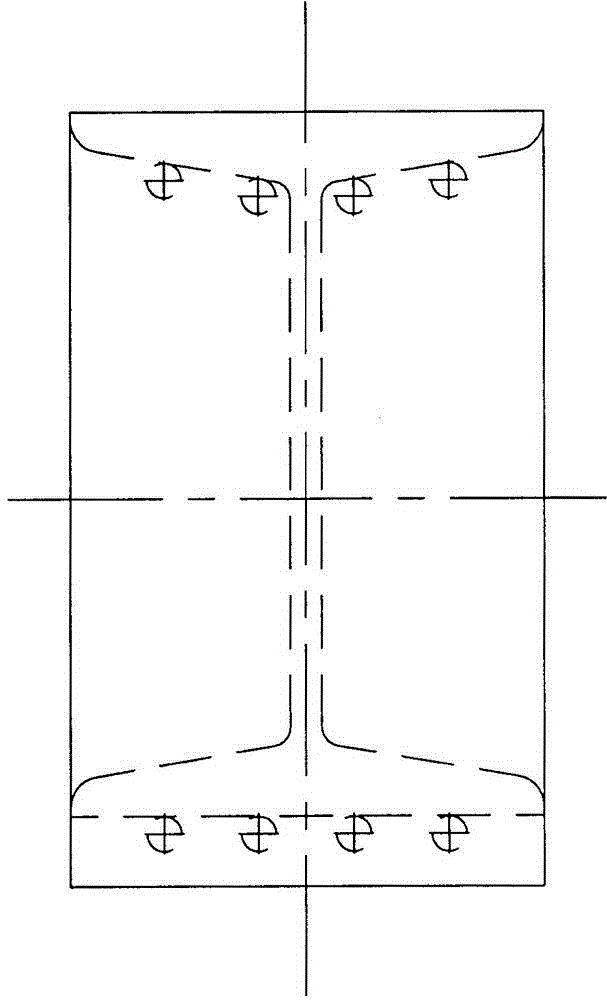

[0018] like figure 1 , 2 , 3, the main girder of the bridge crane of the present invention includes the I-beams that are respectively fixedly connected with the positioning plate 3 as the two ends of the main girder 1, and the bottom surface of the I-beam and the I-beam The bottom surface of the upper wing plate of the steel beam is arranged longitudinally side by side with prestressed steel wire ropes 4, and the horizontal arrangement of the said prestressed steel wire ropes 4 is symmetrically arranged according to the center line of the beam body, and is arranged at intervals along the length direction of the main beam 1 beam body. The prestressed steel wire rope is positioned by the plate and the sheath; the prestressed steel wire rope is covered with a wrapping layer made of stainless steel material, and the wrapping layer is coated with anti-rust grease; the two ends of the main beam 1 are fixed with positioning plate 3, the two ends of the prestressed steel wire rope 4 ...

Embodiment 2

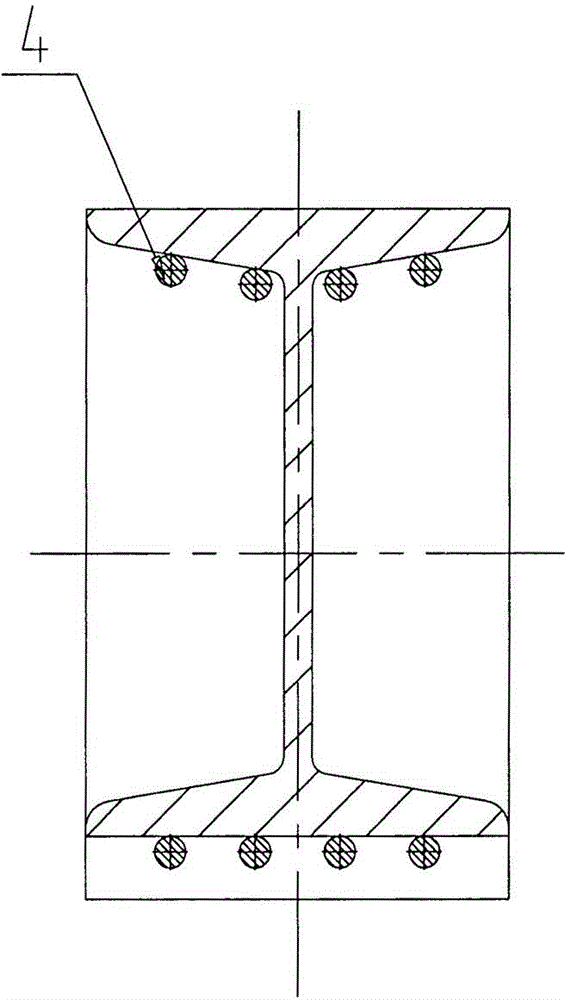

[0021] like Figure 4 As mentioned above, the difference between this embodiment and Embodiment 1 is that the main girder of the bridge crane of the present invention is composed of a rectangular box girder with positioning plates 3 fixedly fixed at both ends, and the rectangular box girder The bottom surface and the bottom surface of the rectangular box girder top plate are provided with prestressed steel wire ropes 4 arranged side by side longitudinally.

[0022] The specifications, quantity and prestress size of the prestressed steel wire rope among the present invention, according to the crane specification, select the bearing strength value that design will increase, select the specification and root number of the steel wire rope and I-beam or rectangular box by the size of the strength value beam specification. The trolley track is set on the main girder. When the crane lifts heavy objects, the steel wire rope bears the maximum tension, thereby greatly reducing the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com