An automatic filling water film injection machine

An automatic filling and film injection technology, which is applied in barrel/cask filling, liquid filling, etc., can solve the problems of secondary or cross-contamination of pure water, and achieve the effects of preventing pollution, avoiding cross-contamination, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

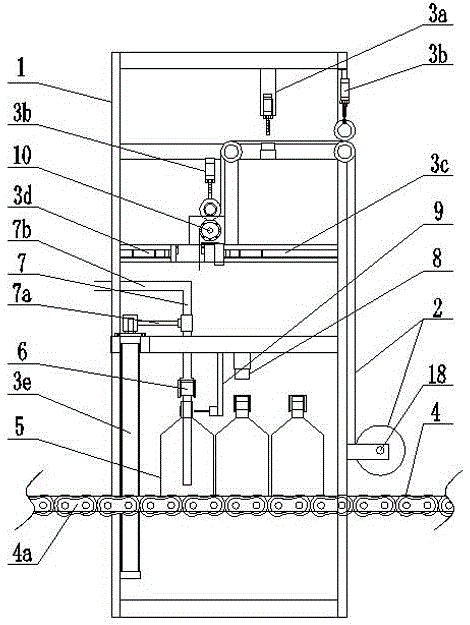

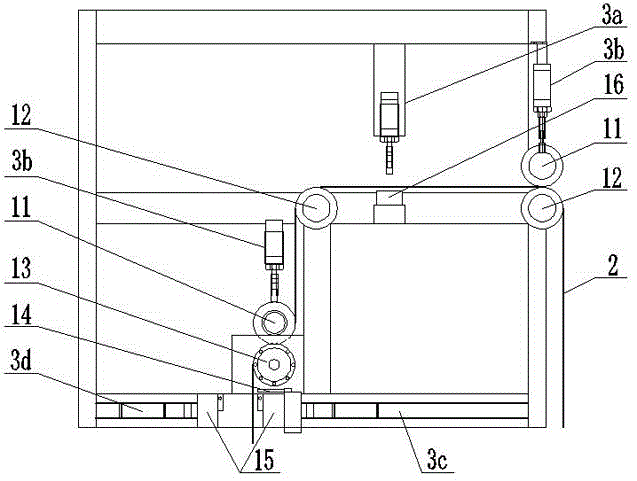

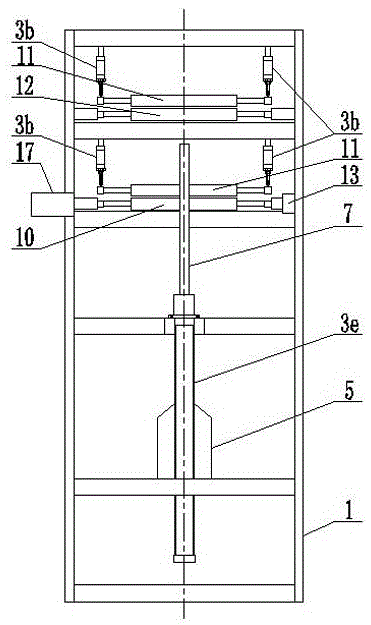

[0020] Such as figure 1 The shown automatic filling water film injection machine includes a feeding device for supplying the bag-shaped film laid inside the barrel for water filling and a device for placing the bag-shaped film in the barrel 5 and pouring pure water The filling assembly is provided with a filling cylinder 3e and a straight-through pipe 7 fixed on the piston rod of the filling cylinder 3e, and the straight-through pipe 7 can be driven up and down by the filling cylinder 3e and can insert the bag-shaped film supplied by the feeding device during the movement, thereby bringing the bag-shaped film into the barrel body 5, and the upper end of the straight-through pipe 7 communicates with the water injection pipe 7b for transporting pure water. The feeding device includes a feed shaft 18 for outputting the plastic film cylinder material 2, a sealing device for quantitatively heat-sealing the plastic film cylinder material 2, and a sealing device for cutting the heat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com