Full-automatic integrated kitchen oil-water separator

An oil-water separator, fully automatic technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to separate oil-water and impurities in sewage, affect the effect of oil-water separation, and urban Problems such as underground pipe network blockage, to achieve the effect of light weight, simple structure, and clean separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

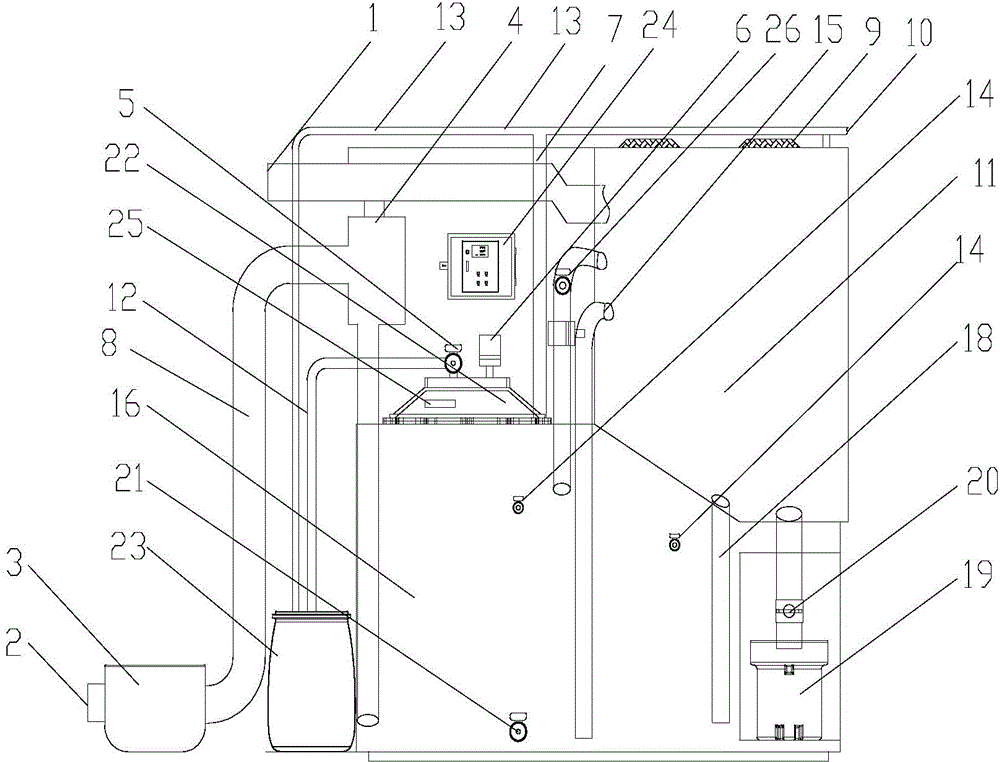

[0019] refer to figure 1 As shown, the embodiment of the present invention provides a fully automatic integral kitchen oil-water separator, which is characterized in that it includes a primary separator (11) and a secondary separator (16), a primary separator (11) and a secondary The separators (16) are connected by a separation guide pipe (18), and the bottom of the primary separator (11) is provided with an impurity sludge water filter (19), and the impurity sludge water filter (19 ) has an impurity sludge discharge port, and the secondary separator (16) is provided with a grease stirring separator (6) and a grease storage heating chamber (22), and is externally connected with a grease collection bucket (23) and a sewage drain Outlet (2), wherein, the sewage enters the primary separator (11) through the sewage inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com