Method for quickly synthesizing metal organic framework material MIL-101

A metal-organic framework and fast technology, applied in the field of polymer materials, can solve problems such as crystal damage, achieve low operating costs, low investment, and shorten synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

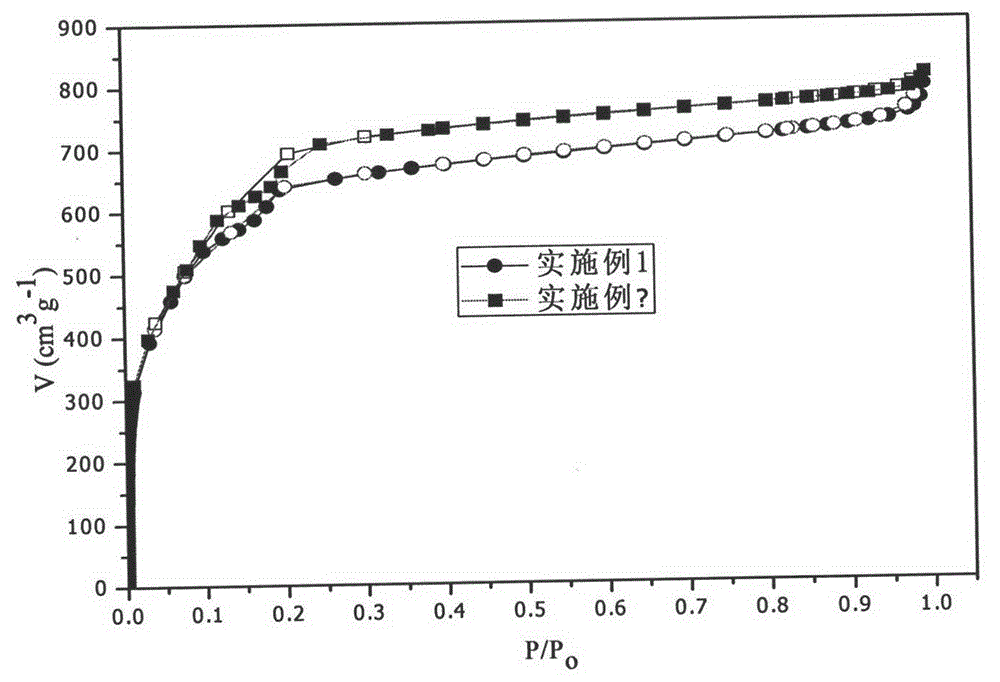

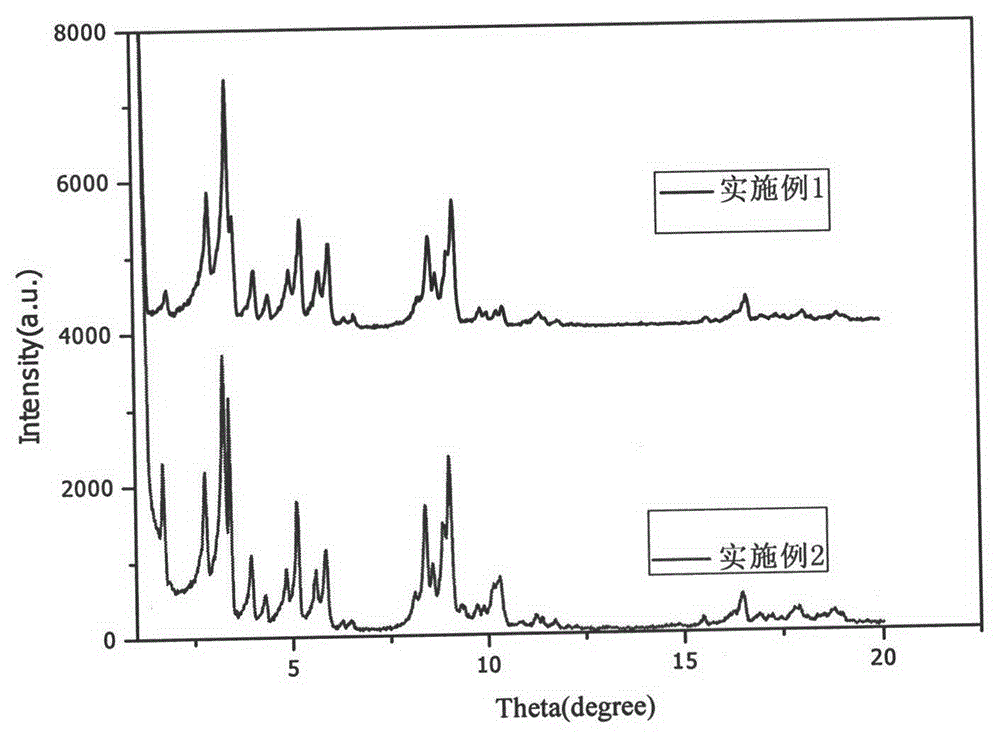

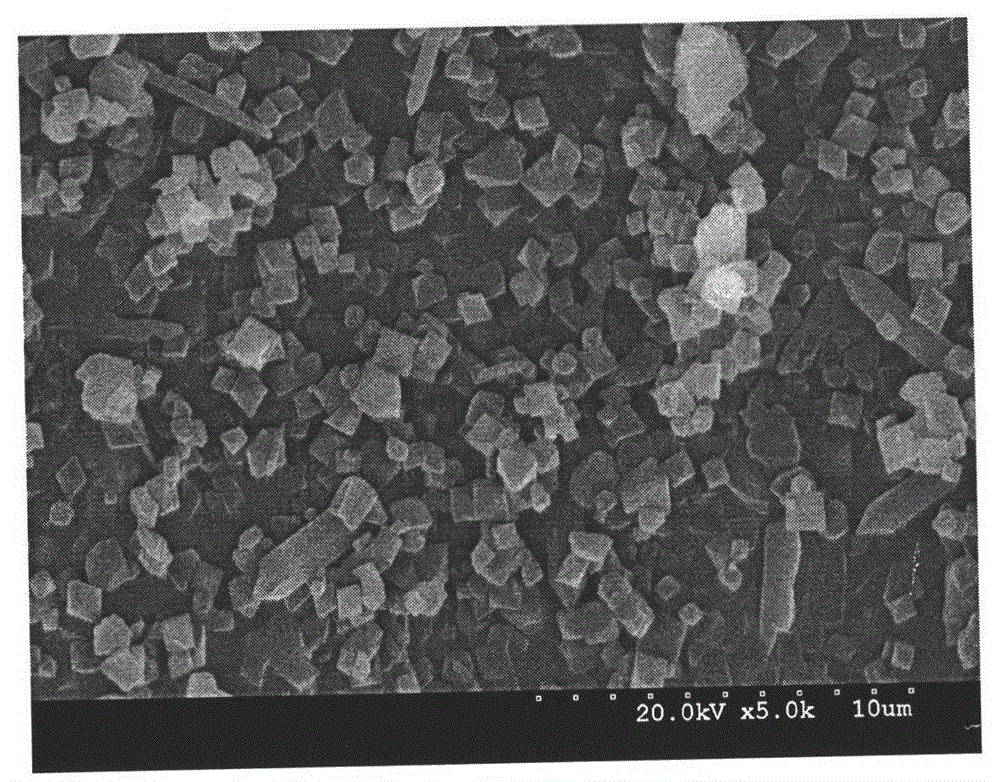

Embodiment 1

[0014] Add 4.00g of chromium nitrate, 0.45ml of hydrofluoric acid with a mass concentration of 40%, and 1.66g of terephthalic acid into 48g of water, stir and mix, then add to a closed reaction kettle, and finally add 0.02g of carbon nanotubes, and react at 220°C for 2h . After the reaction was completed, the temperature was slowly lowered to room temperature, and then centrifuged. The solid obtained in the upper layer was washed with dimethylformamide and absolute ethanol, and vacuum-dried and activated at 150°C to obtain the metal-organic framework material MIL-101.

Embodiment 2

[0016] Add 4.00g of chromium nitrate, 0.23ml of hydrofluoric acid with a mass concentration of 40%, and 1.66g of terephthalic acid into 48g of water, stir and mix, then add to a closed reaction kettle, and finally add 0.8g of nano-carbon fibers, and react at 220°C for 0.5h . After the reaction was completed, the temperature was slowly lowered to room temperature, and then centrifuged. The solid obtained in the upper layer was washed with dimethylformamide and absolute ethanol, and vacuum-dried and activated at 150°C to obtain the metal-organic framework material MIL-101.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com