Side-group long-chain azidated epoxy resin and synthesis technique thereof

A technology of nitriding epoxy resin and nitriding epoxy resin, applied in epoxy resin coatings, coatings, etc., can solve the problems of insufficient surface adhesion of wet substrates, poor toughness of epoxy resin-based anti-corrosion coatings, etc. , to achieve the effect of long-term effect, strong adhesion and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

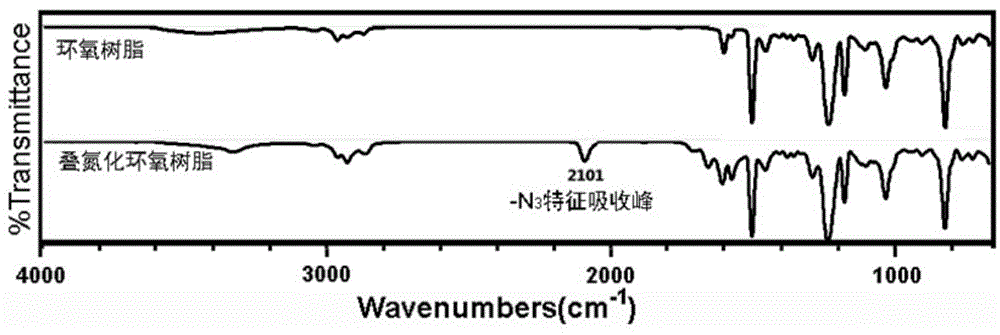

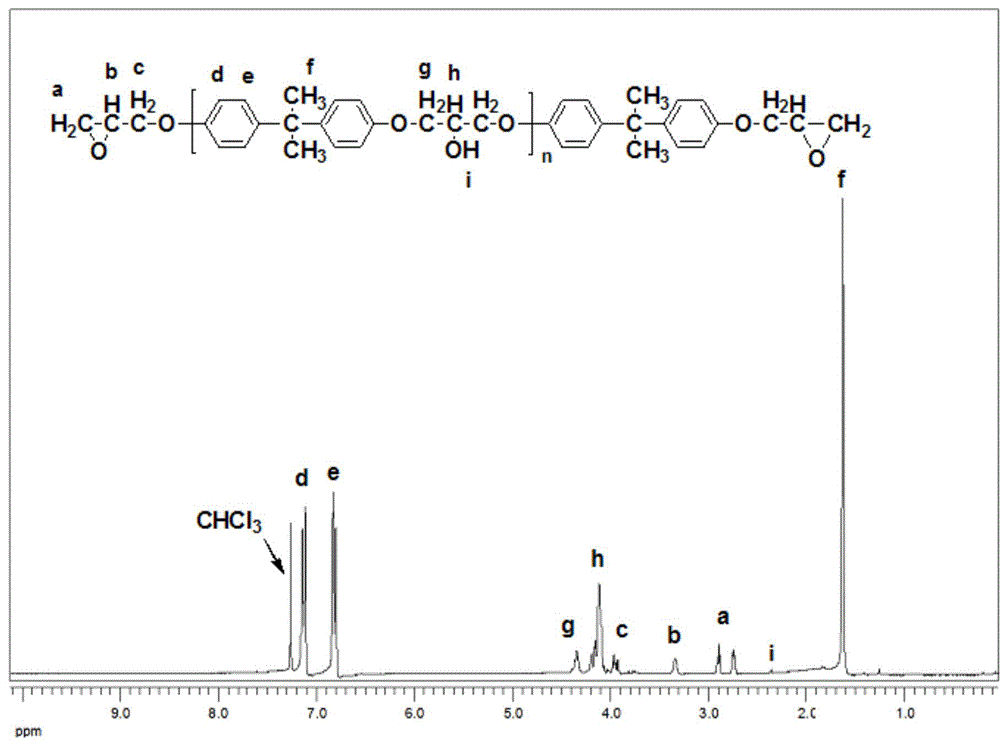

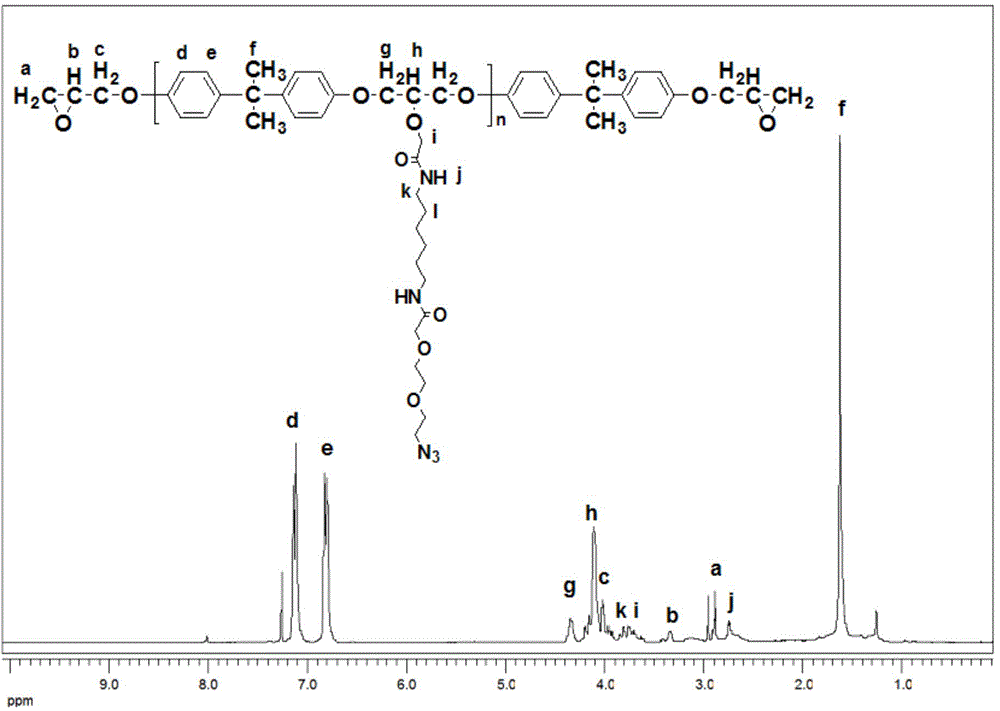

[0038] Two azide fragments were synthesized using 2-chloroethanol and 3-chloropropanol respectively: (a) HO-CH 2 CH 2 -N 3 and (b) HO-CH 2 CH 2 CH 2 -N 3 . Then HDI and TDI were selected to carry out chain extension grafting on E20 epoxy resin, and four kinds of side group long chain azide epoxy resins with different structures were prepared, respectively:

[0039]

[0040] The synthetic process parameter of embodiment one to embodiment four of the present invention is as shown in table 2:

[0041] Table 2 Example synthesis process parameters

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com