Preparation method for polystyrene elastic waterproof coating

A polystyrene and waterproof coating technology, applied in the chemical industry, can solve the problems of high toxicity of tar gas, short construction period, poor environmental protection, etc., and achieve the effect of convenient and simple preparation, less investment in equipment, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

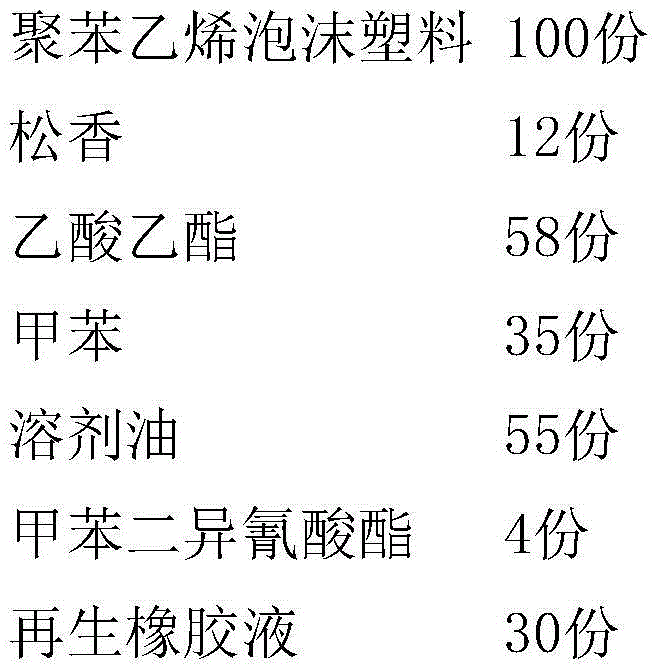

Embodiment 2

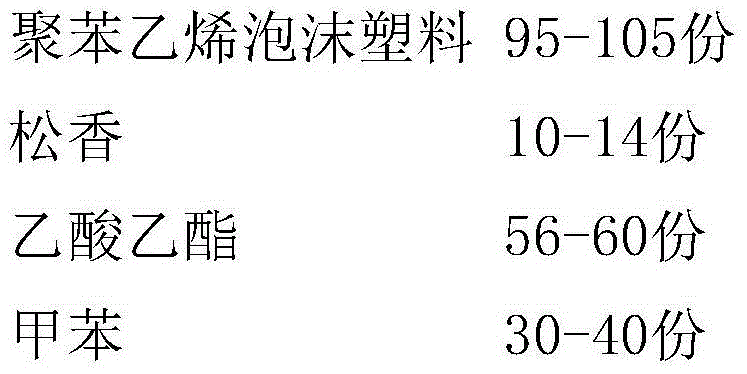

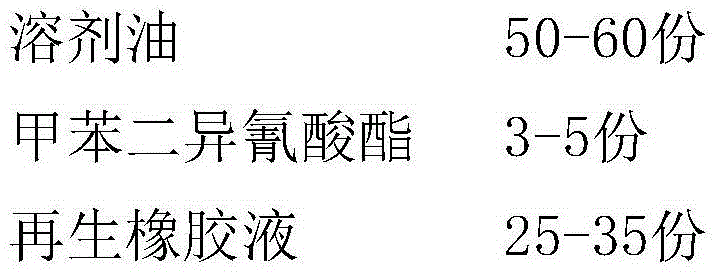

[0025] A polystyrene elastic waterproof coating is characterized in that it is made up of the raw materials of the following components:

[0026]

[0027]

[0028] The method for preparing polystyrene elastic waterproof coating of the present invention comprises the following processing steps:

[0029] a. Weigh the polystyrene foam according to the formula quantity, and then cut it to a length of 2-4cm.

[0030] b. choose a reactor that is provided with a jacket, put all the polystyrene foam plastics after cutting in step a into it, then add rosin, ethyl acetate, toluene, solvent naphtha and toluene in the above-mentioned raw materials according to the formula amount Diisocyanate is added to it, under constant stirring and heated to 48-58°C, react for 4-5h.

[0031] c. After the reaction in the above step b is completed, add the regenerated rubber industry in the above solution into the reaction kettle according to the formula amount, and stir evenly.

[0032] d. The m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap