Heat Exchanger for Cooling Towers

A technology for heat exchange devices and cooling towers, which is applied in the direction of water shower coolers, heat exchanger types, direct contact heat exchangers, etc., and can solve the problems of aggravated load changes in the filling area, excessive wind resistance, and low cooling tower cooling efficiency. problems, to achieve the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

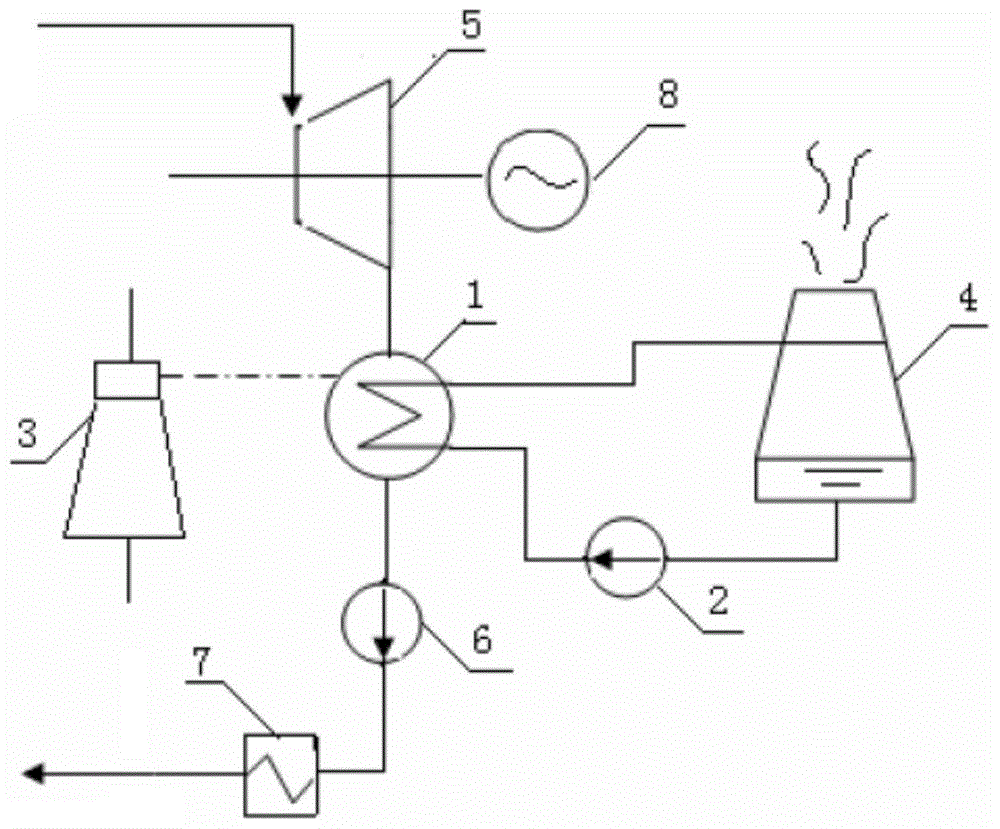

[0037] Cooling tower 4 is a cold end system, with figure 1 The power generation system of the thermal power plant shown as an example is explained. It provides circulating cooling water with the required temperature and flow rate to the condenser 1 to cool the exhausted steam in the main system, and absorbs the latent heat of vaporization of exhausted steam to make it become Condensed water is formed to complete the cycle; in addition, it also provides guarantee for the formation and maintenance of the vacuum of the condenser. The working process of the power generation system is as follows: the steam turbine 5 works under the impetus of external high-temperature and high-pressure steam to drive the generator 8 to generate electricity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com