Extruder cleaning pad cooling device and use method thereof

A cooling device and extruder technology, applied in the field of metallurgical equipment, can solve the problems of prolonging the production cycle, affecting the service life, long cooling time, etc., and achieving the effects of reliable and stable torsional power, prolonged service life and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

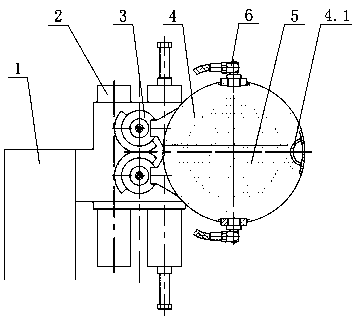

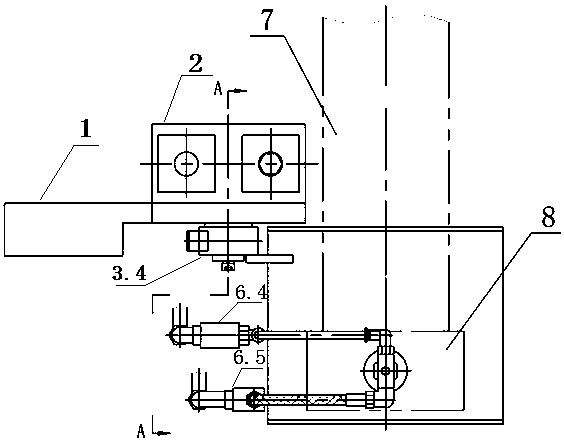

[0027] Such as figure 1 , figure 2 As shown, an extruder cleaning pad cooling device at least includes a cleaning pad 8, and the cleaning pad 8 is fixed on the front end of the cleaning shaft 7, and also includes a fixing seat 1, a power device 2, a transmission device 3, an upper half Cover 4, lower half cover 5 and pressure spray device 6, one side of the fixed seat 1 is provided with a power device 2, and the other side of the fixed seat is provided with a transmission device 3, and the power device 2 and the transmission device 3 relative settings;

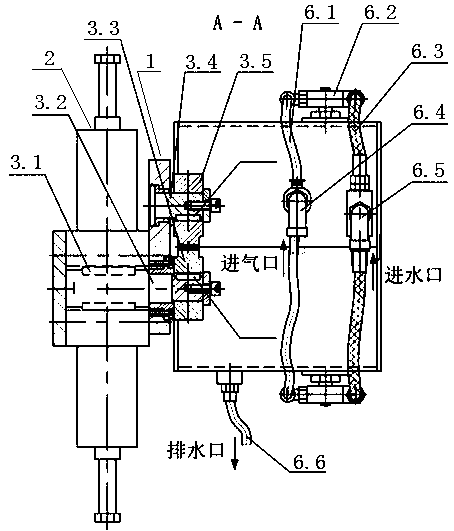

[0028] The transmission device 3 includes an output shaft 3.2, a driving gear 3.3, a pin shaft 3.4 and a driven gear 3.5, one end of the output shaft 3.2 passes through the fixed seat 1 and is connected to the power unit 2, and the other end of the output shaft 3.2 is connected to the driving gear 3.3 connection, the driven gear 3.5 is connected with the fixed seat 1 through the pin shaft 3.4, and meshes with the driving ge...

Embodiment 2

[0032] On the basis of the above embodiments, the power device 2 is a double-rack swing cylinder with a magnetic switch, and its function is to use compressed air to drive the output shaft to perform reciprocating rotary motion within a certain angle range. The double-rack swing cylinder can be output with multiple torques to ensure sufficient torsional power, and the output torsional power is reliable and stable, and the transmission efficiency is high; it is installed on the fixed seat by screws, and the structure is reliable.

[0033] One end of the output shaft 3.2 passes through the fixed seat 1, and is connected with the power unit 2 through the key one 3.1, the other end of the output shaft 3.2 is connected with the driving gear 3.3 through the key three 3.7, and the pin shaft 3.4 passes through the fixed seat 1, And be connected with driven gear 3.5 by key two 3.6. After assembly, it should be ensured that the center distance between the pin shaft 3.4 and the output sh...

Embodiment 3

[0035] Such as image 3As shown, further, the pressure spray device 6 includes an atomizing nozzle 6.2, an air hose 6.1, an air tee joint 6.4, a water hose 6.3 and a water tee joint 6.5, and the top of the upper half cover 4 is connected to the The bottom of the lower half cover 5 is equipped with atomizing nozzles 6.2 respectively. The left and right sides of the atomizing nozzles 6.2 are air inlets and water inlets respectively. The two passages of the air tee joint 6.4 are connected, the water inlets of the two atomizing nozzles 6.2 are respectively connected with the two passages of the water tee joint 6.5 through the water hose 6.3, and the air tee joint 6.4 is connected to the The other channel of the waterway tee joint 6.5 is used as the total air inlet and water inlet respectively, and is connected with the compressed air station and the cooling water station respectively, so that the two nozzles can be opened and closed synchronously.

[0036] Further, the atomizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com