Testing method and testing device for low-temperature cracking resistance performance of asphalt beam

A technology of test device and test method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of unsuitability for popularization and high construction cost, and can make up for the insufficient evaluation of low temperature performance of asphalt, simple structure, rich low temperature The effect of performance evaluation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

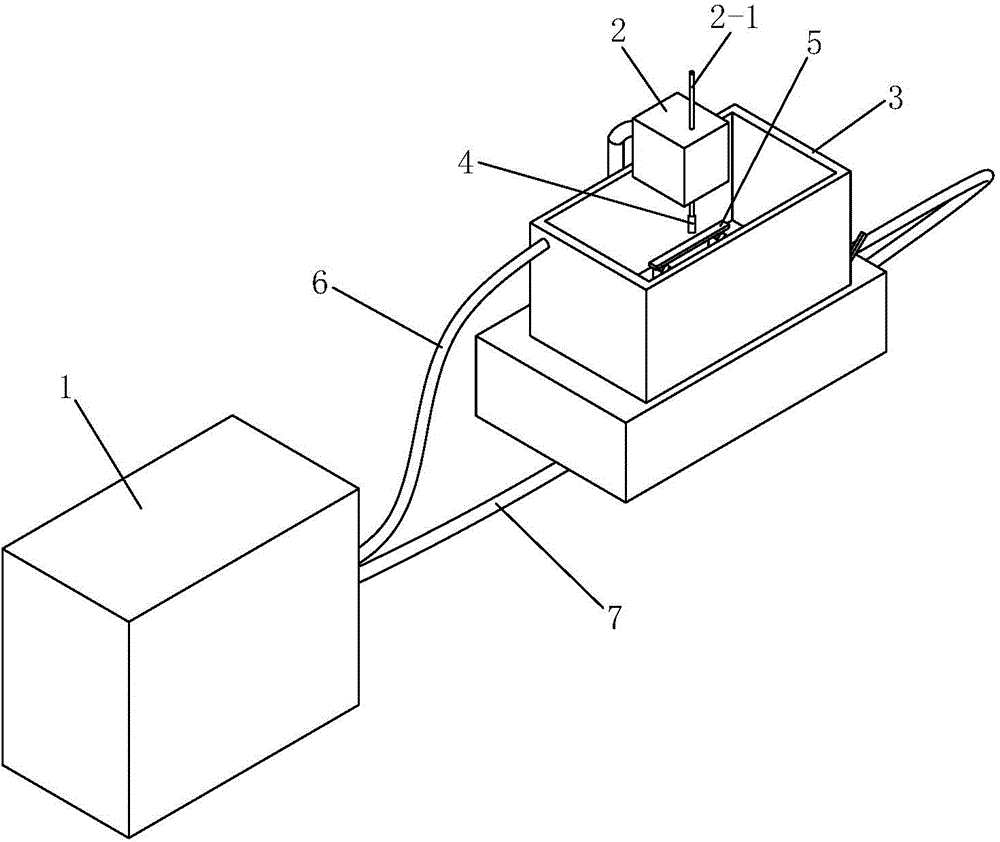

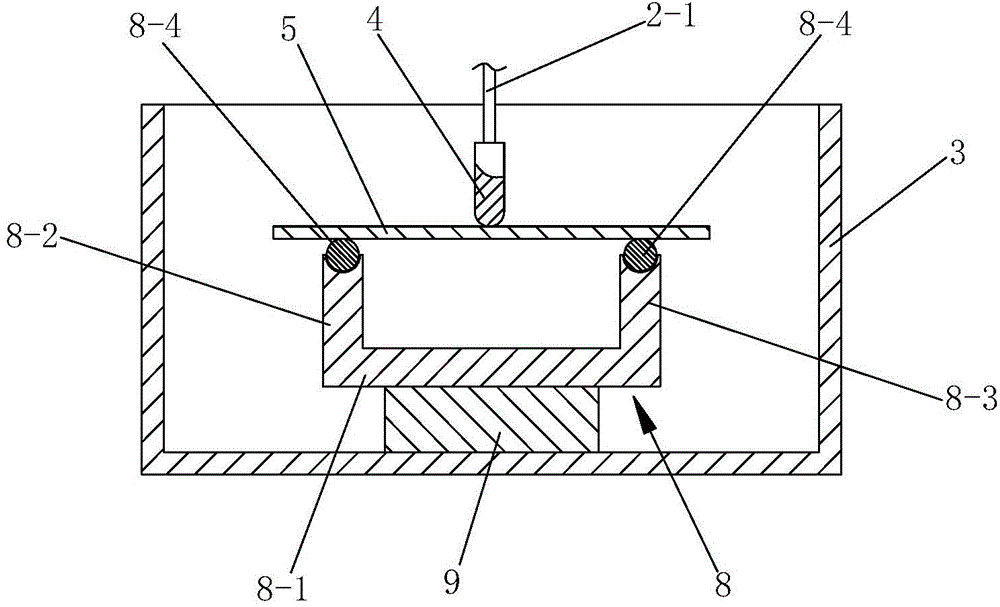

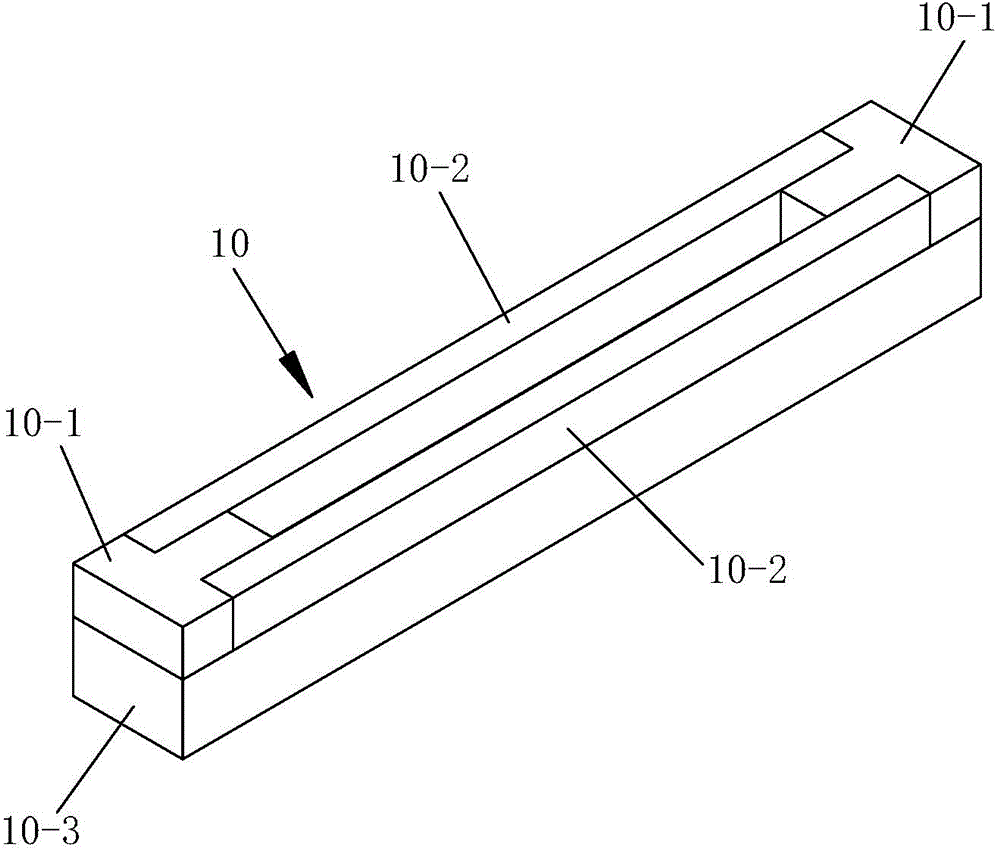

[0038] Such as figure 1 and figure 2 The shown test device for the low-temperature cracking resistance of asphalt beams includes a test tank 3 filled with cooling liquid, and a bracket 8 for carrying an asphalt beam test piece 5 is arranged in the test tank 3, and the bracket 8 and the asphalt The beam specimen 5 forms a two-point support, and the top of the test tank 3 is provided with a loading device for applying a constant vertical load to the asphalt beam specimen 5. The loading head 4 that the parts abut against. Specifically, a support 9 is provided on the inner bottom wall of the test tank 3 , and the support 8 is installed on the support 9 .

[0039] The test device lowers the asphalt beam specimen 5 to the test temperature through the cooling liquid, and uses three-point loading to bend the asphalt beam specimen 5 to start the low-temperature cracking performance test of the asphalt beam. The mechanical principle is simple, and the processing of the bracket 8 Sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com