Method for detecting chemical components comprising nickel, chromium and manganese of stainless steel

A technology of chemical composition and detection method, which is applied in the field of stainless steel, can solve problems such as cumbersome process and prolong detection cycle, and achieve the effect of simple preparation operation, accurate detection result, accurate and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

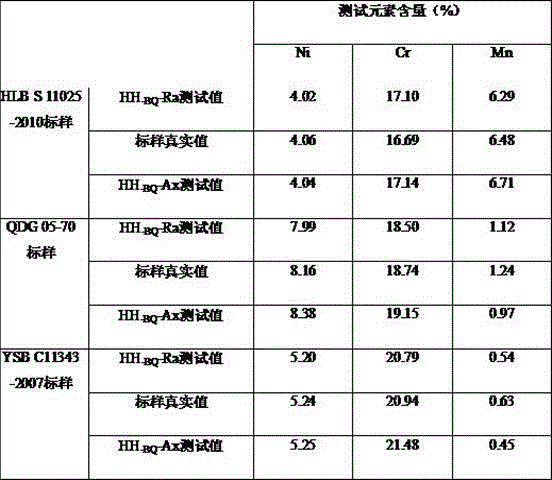

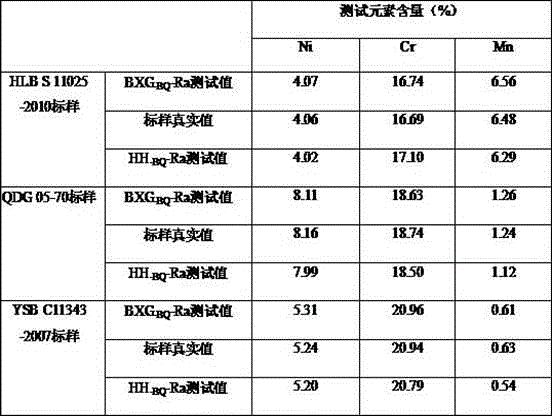

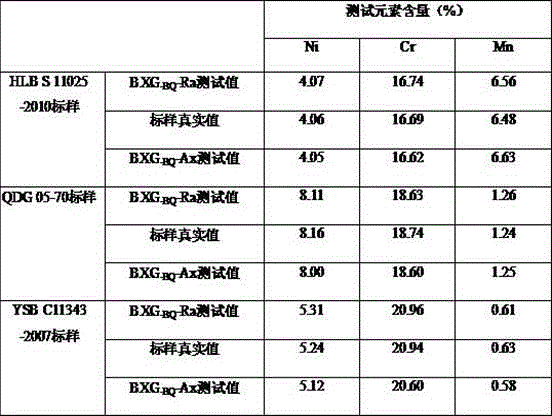

[0011] Stainless steel standard sample and Ni, Cr, Mn content: GSB03-1546-2003 (Ni: 4.04%, Cr: 15.66%, Mn: 0.615%), YSBC 41320c-2006 (Ni: 9.86%, Cr: 18.56% , Mn: 0.803%), YSB C11311-93 (Ni: 11.18%, Cr: 19.32%, Mn: 6.52%), YSB C37362-10 (Ni: 8.49, Cr: 18.56, Mn: 1.44), GBW(E) 010215 (Ni: 4.05, Cr: 12.48, Mn: 9.45), select the standard curve (BXG -BQ ). Ni standard solution (GSB 04-1740-2004), Cr (GSBG62017-90), Mn (GSB G 62019-90), Fe metal pure substance standard sample (YSB C 11001-99) are used to prepare a series of mixed standards with different concentrations Solution (HH -BQ ). Stainless steel 201 standard sample HLB S 11025-2010 ZG1Cr17Mn6Ni5N (Ni: 4.06, Cr: 16.69, Mn: 6.48), stainless steel 304 standard sample QDG 05-70 0Cr18Ni9 (Ni: 8.16, Cr: 18.74, Mn: 1.24), YSB C11343- 2007 (Ni: 5.24, Cr: 20.94, Mn: 0.63) three stainless steel standard samples were used to verify the accuracy of the two working curves and detection methods. The chemical reagents such as nitric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com