System for reducing the wiping gas consumption in an air knife

A technology of pressurized gas and air flow, which is applied in the direction of drying gas arrangement, device for coating liquid on the surface, rearrangement of coated substances, etc., and can solve problems such as thermal expansion and deformation of nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0049] When putting this reduction into practice, an embodiment of the device according to the invention is first installed on a gas wiping nozzle (not shown).

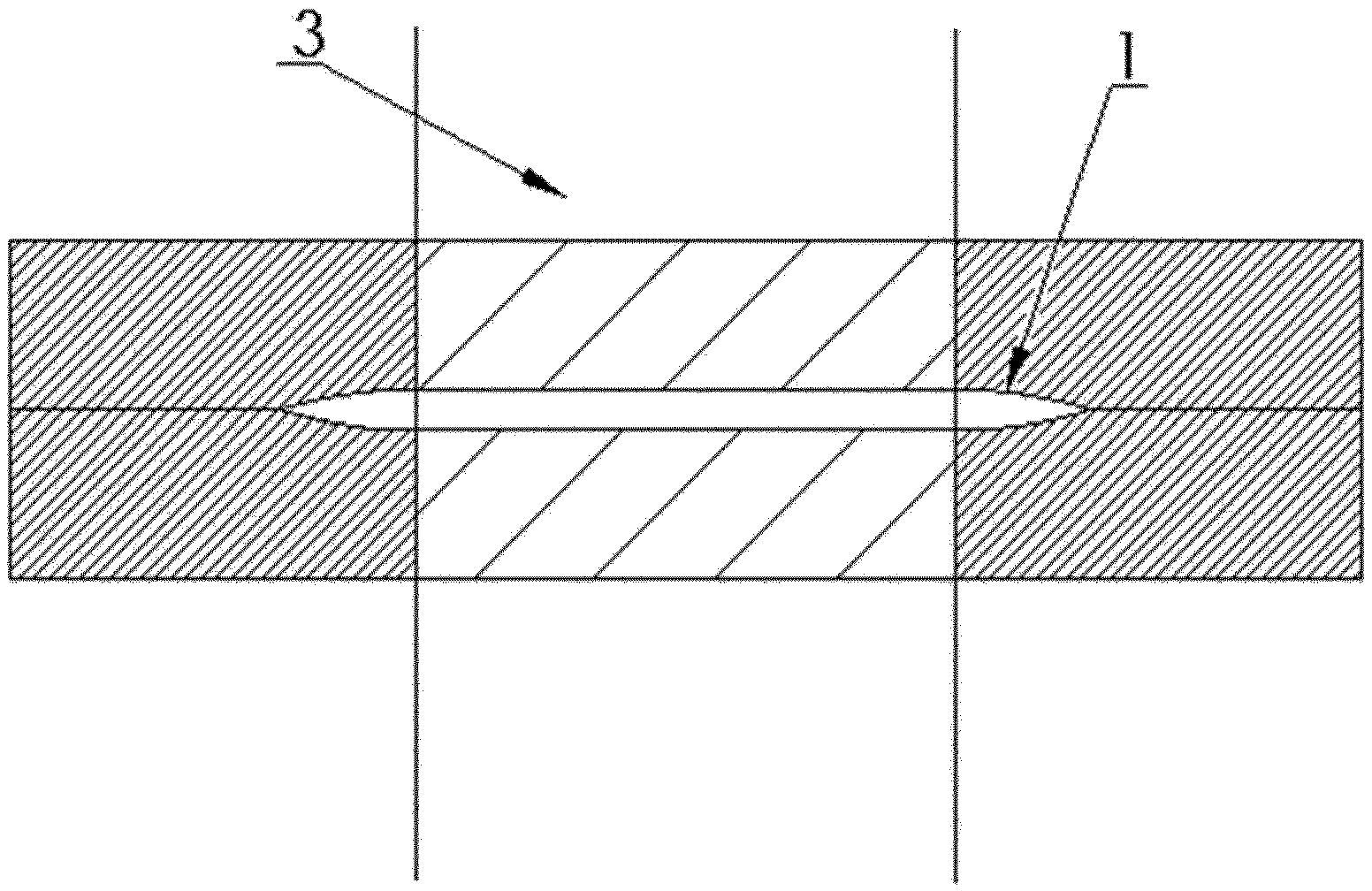

[0050] In this example, the nozzle 1 is about 2.3 m long; the opening 4 of this nozzle may be between 1 mm and 2 mm.

[0051] The cable 9 has a diameter of 5 mm and is applied or withdrawn by means of a carriage with two sheaves 6, 7, of which there is one carriage 10 on each side of the nozzle. The carriage is moved by a motor powered screw. The internal movement of the carriage 10 is limited by carriage stoppers 12 .

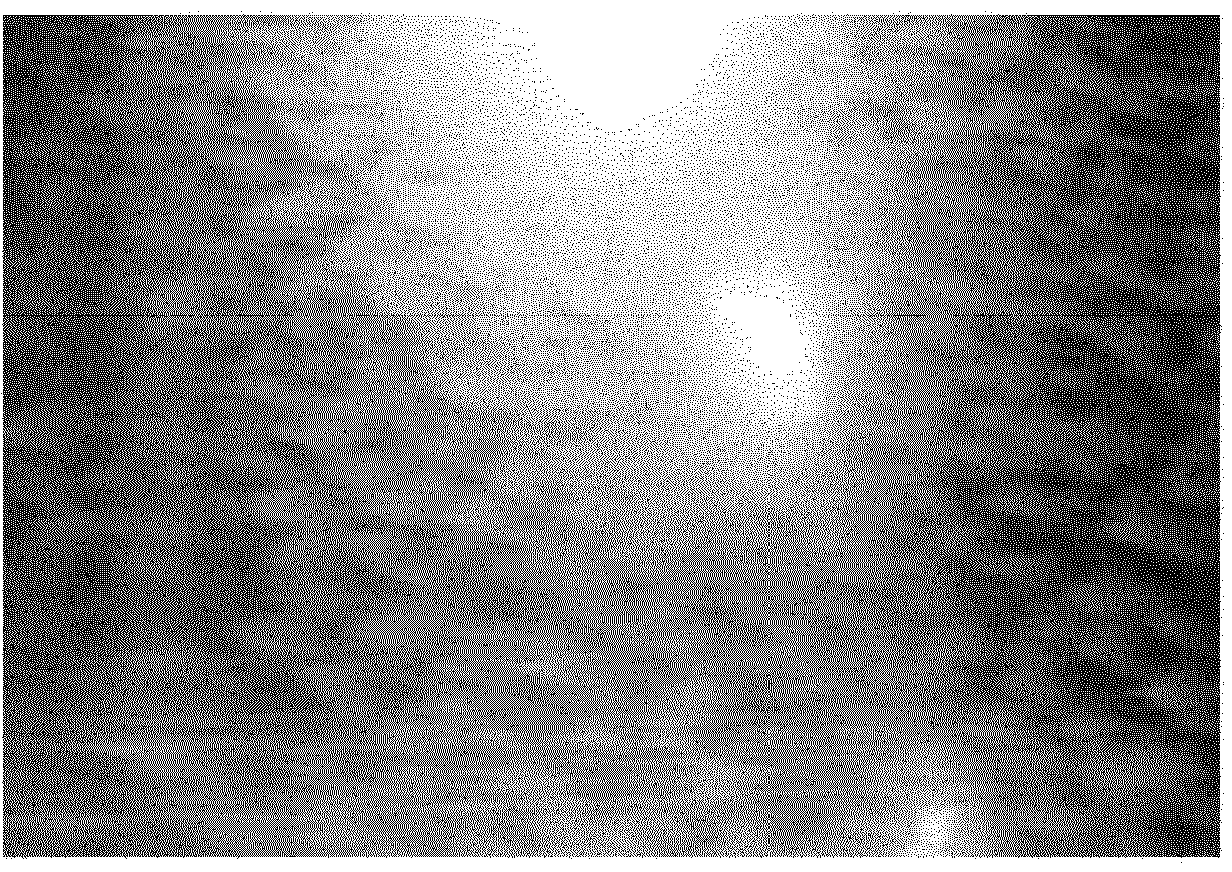

[0052] Tested using an internal pressure of 220mb in the chamber and a very small Pitot tube (Pitot tube) at the outlet ( Figure 8 ) to measure dynamic pressure. On the right side of the figure it can be observed that the dynamic stress can be significantly reduced where the cable is applied. A detailed analysis of the results showed that the residual flow at the applied cable was approximately 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com