Ring CVT

A continuously variable transmission and ring-type technology, which is applied in the direction of vehicle gearboxes, friction transmission devices, transmission components, etc., can solve the problems of rising manufacturing costs of trunnions, inability to grind, and poor processing efficiency, and achieve uniform assembly operations and processing Easy and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] [First example of embodiment]

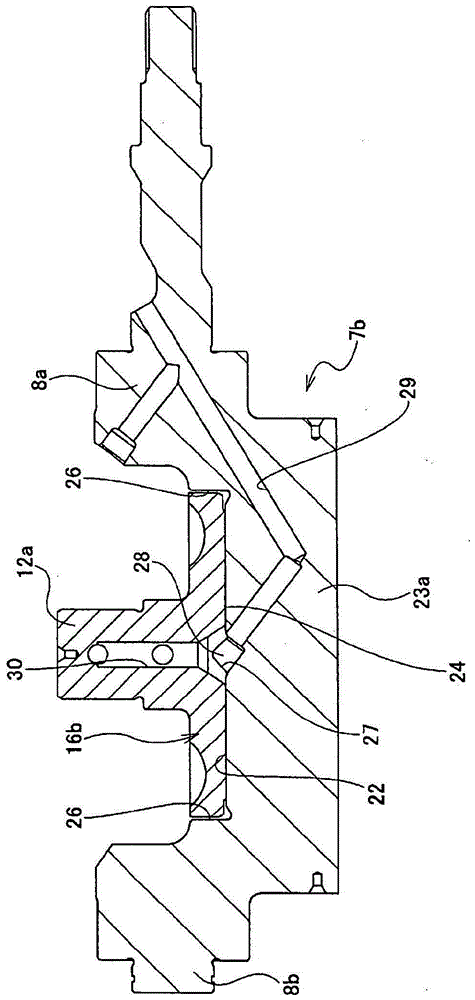

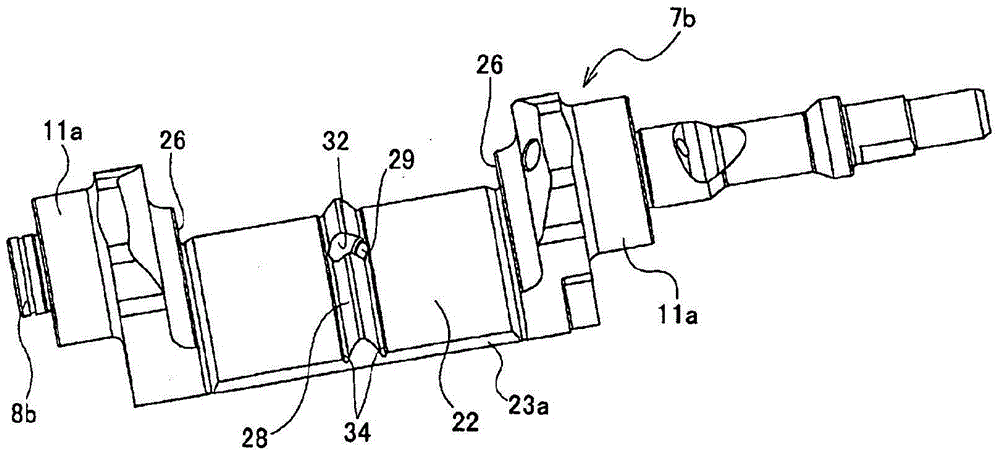

[0076] Figure 1~Figure 8 It shows the first example of the embodiment of the present invention. In addition, this example is characterized by the following structure: in order to stabilize the shifting operation, the outer ring 16b constituting the thrust ball bearing 13a is supported by the support beam portion 23a of the trunnion 7b so as to be swingable relative to the support beam portion 23a, In addition, the outer ring 16 is prevented from being displaced in the axial direction of the support beam portion 23a. The structure and function of the other parts are the same as in the second example of the conventional structure.

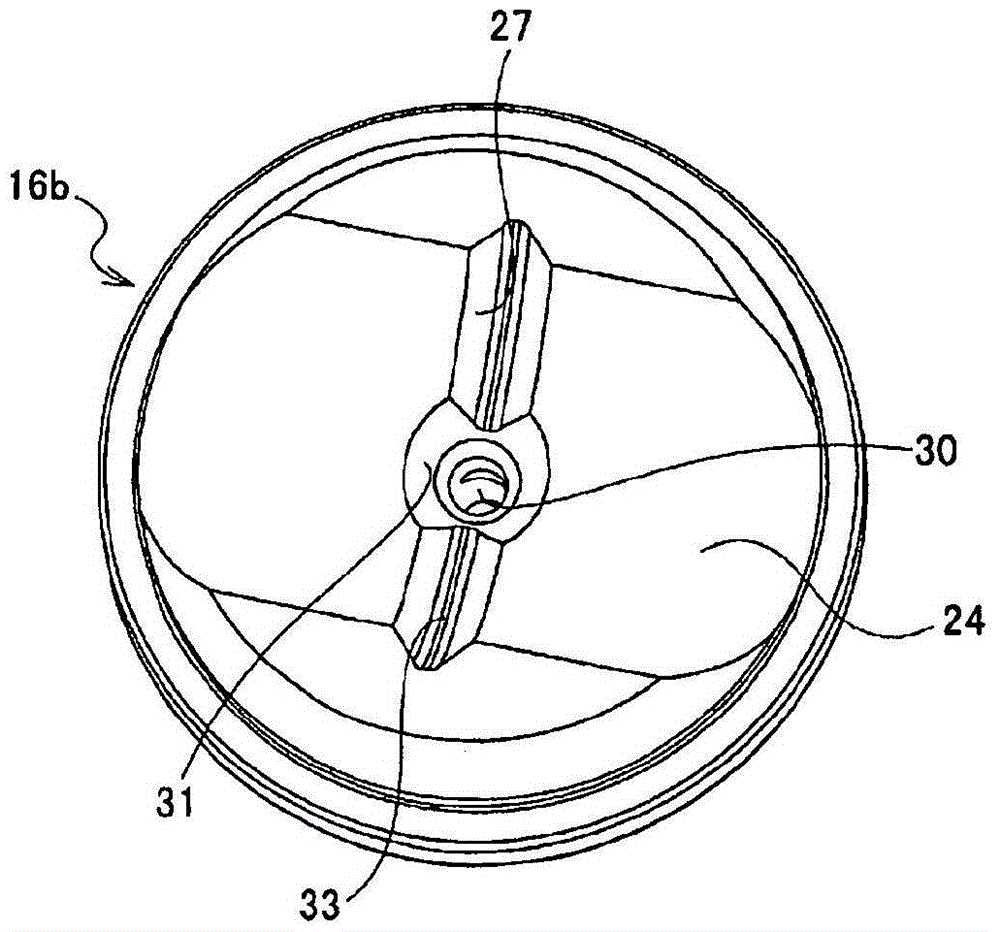

[0077] The outer ring 16b is supported by the concave portion 24 provided on the outer surface of the outer ring 16b and the cylindrical convex surface 22 of the support beam portion 23a so as to be supported on the input disc 2 and the output disc 5 ( See Figure 21 ) Swing displacement in the axial direction. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com