Self-propelled field weeding machine

A weeding machine, self-propelled technology, applied in the direction of land preparation machinery, agricultural machinery and implements, applications, etc., to achieve good profiling effect, simple structure, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

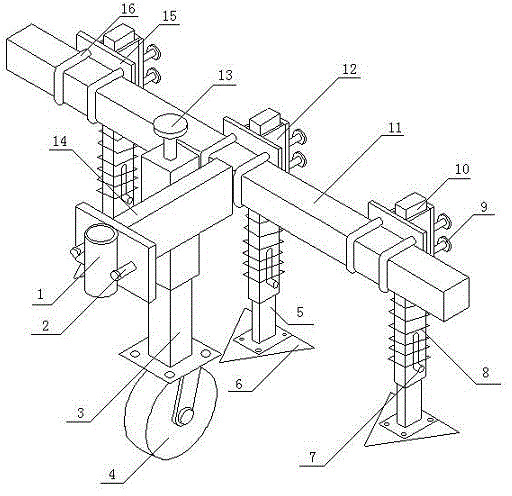

[0014] like figure 1 As shown, a self-propelled field weeder includes a connecting pin hole 1, a balance adjustment bolt 2, a telescopic tube 3, a lift-limiting wheel 4, a telescopic handle 5, a hoe 6, a pin 7, a buffer spring 8, a top wire 9, Hoe shovel handle 10, large frame 11, fixing seat 12, lifting wheel adjustment handle 13, connecting frame 14, fixing plate 15, U-bolt 16, the fixing seat 12 is welded and fixed on one side of the fixing plate 15, the fixing plate 15 The frame 11 is fixed by U-shaped bolts 16; the upper end of the telescopic handle 5 passes through the square hole of the fixed seat 12 and is fixed in the fixed seat 12 by the jacking wire 9, and the lower end of the telescopic handle 5 is fixed with a shovel 6 by bolts; The middle part of the large frame 11 and the opposite side of the fixed seat 12 are welded and fixed to the connecting frame 14, and the front end of the fixed connecting frame 14 is welded and fixed to the connecting pin hole 1 in the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com